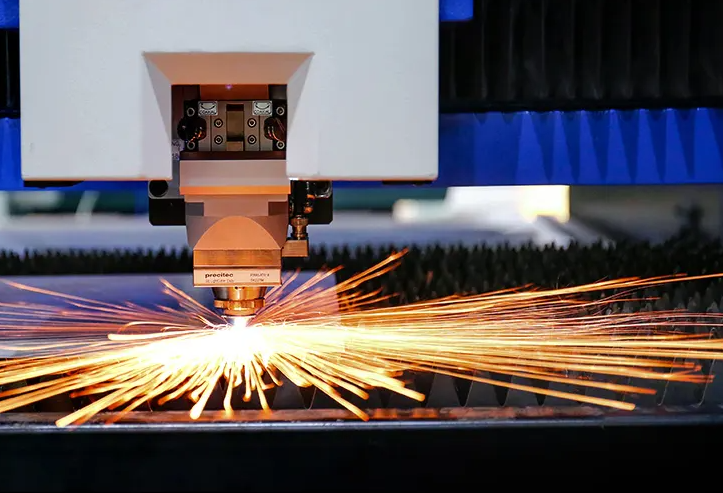

Laser cutting service technology has been widely penetrated into various processing industries, such as metal processing, steel, aerospace, automotive manufacturing, medical equipment and so on. Firstly, the laser cut beam focusing spot has a very small irradiation area, which can be used for micro and precision machining, such as the processing of micro cracks and micro holes.

sheet metal fabrication definition and classification: sheet metal is a pointer to the metal sheet 6mm below a comprehensive cold processing process, the process mainly includes: blanking, bending, welding, and surface treatment.

Which blanking can be divided into number punching and laser cutting according to the processing mode.

Number punching is mainly used to cut cold-rolled plates and hot-rolled plates below 3mm, aluminum plates below 4mm, and stainless steel below 2mm, the maximum plate processing size is 1250mm*4000mm;

Laser cutting machine applications are wide, there are three types, YAG solid, CO2, and fiber laser cutting machine.

Advantages and characteristics of laser cutting: for many varieties, many batches, small batches, and non-standard and high precision processing requirements, laser cutting has obvious advantages.

Compared with the traditional process of NUMERICAL control, it has the following characteristics:

1, high degree of flexibility, cutting speed, and then improve production efficiency, shorten the production cycle.

2, high degree of automation, simple operation, reduce labor intensity.

3, high material utilization rate, reduce production costs, improve economic benefits.

4, good adaptability of materials, no prop wear, effectively prolong life.

(1) It is beneficial to optimize the process, reduce the processing process and reduce the production cost. This is due to the one-time operation of sheet forming and the welding of the sleeve, reducing the use of the mold, thus reducing the production time.

(2) to improve the efficiency of laser cutting. Using software programming to develop a more reasonable cutting scheme can not only reduce the use and waste of materials but also effectively improve the processing efficiency.

(3) It is beneficial to product development. As the production cycle is shortened, the speed of research and development of new products will be increased to explore new market needs.

Laser welding, laser marking, and laser cutting are three applications of laser, and laser cutting with cutting size, cutting speed, can cut thicker plate incomparable advantages, high power laser cutting has been widely recognized in the market. But because the high power laser cutting technology is still in the initial stage of popularity, some operators of high power laser cutting skills are not very skilled, laser cutting in the application process there are three technological difficulties.

1, laser head all lenses without pollution, are clean;

2, the water temperature of the water tank is normal, and the laser has no condensation phenomenon;

3, cutting gas purity, gas flow, no leakage phenomenon.

Problem one: there are burrs on the bottom

Possible causes:

1. The nozzle diameter is too small to meet the processing requirements;

2, negative defocus does not match, should increase the negative defocus, modulation appropriate position;

3, the pressure is small, resulting in a burr at the bottom, unable to fully cut.

Solutions:

1, the selection of a large diameter nozzle, can increase the gas flow;

2, increase the negative defocus so that the cutting section reaches the bottom position;

3, increasing the air pressure, can reduce the bottom burr.

Tube laser cutting equipment

Problem two: cutting with stripes

Possible causes:

1, the nozzle selection is wrong, the nozzle is too large;

2, the air pressure setting is not correct, the setting air pressure is too large to lead to overburning stripes;

3, the cutting speed is not correct, the cutting speed is too slow or too fast will cause full overburning.

Solutions:

1, replace the nozzle, replace the nozzle with a small diameter, such as 16mm carbon steel bright cutting, high-speed nozzle D1.4 can be selected; 20mm carbon steel bright surface can choose high-speed nozzle D1.6;

2, reduce the cutting pressure, improve the quality of end cutting;

3, adjust the cutting speed, power, and cutting speed match properly, in order to achieve the following effect on the right.

Problem three: there are nodules at the bottom

Possible causes:

1, the nozzle selection is too small, the cutting focus does not match;

2, pressure is too small or too large, cutting speed is too fast;

3, plate material is poor, plate quality is not good, and the small nozzle is difficult to remove tumor residue.

Solutions:

1. Replace the large-caliber nozzle and adjust the focal point to the appropriate position;

2. Increase or decrease the air pressure until the airflow is appropriate;

3, choose a good plate.

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.