sheet metal fabrication has been widely used in many fields, such as the electronic and communication industry, car industry, and then, the medical machinery, has been widely used, we ordinary people also often used sheet metal fabrication and manufacturing of products, such as TV, mobile phone, refrigerator, computer, electric cooker and so on.

There are many sheet metal materials suitable for stamping processing. Sheet metal materials widely used in the electronic and electrical industry include:

SPCC refers to the continuous rolling of steel ingot into steel coil or sheet of required thickness by the cold rolling mill. SPCC surface without any protection, exposure to the air is easy to be oxidized, especially in the humid environment, the speed of oxidation, dark red rust, in use to spray paint, electroplating or another protective surface.

The base material of SECC is a general cold-rolled steel coil, which becomes an electro galvanizing product after a continuous electro galvanizing production line goes through degreasing, pickling, electroplating, and various post-treatment processes. SECC not only has the mechanical properties and similar machinability of ordinary cold-rolled steel sheets but also has superior corrosion resistance and decorative appearance. In the electronic products, home appliances and furniture market have great competitiveness and substitution. For example, SECC is commonly used in computer cases.

Hot-dip galvanized steel coil refers to the semi-finished product after hot pickling or cold rolling, after cleaning, annealing, immersed in the temperature of about 460°C melt zinc tank, the steel sheet plated with zinc layer, and then after quenching and leveling and chemical treatment. SGCC material is harder than SECC material, has poor ductility (avoiding deep pumping design), a thicker zinc layer, and poor weldability.

It has stainless steel SUS301

Cr(chromium) content is lower than SUS304, poor corrosion resistance, but after cold processing can obtain a good tension and hardness, and good elasticity, used for spring and anti-EMI.

Stainless steel SUS304

One of the most widely used stainless steel, containing Ni(nickel) than Cr(chromium) steel is rich in corrosion resistance, and heat resistance, with very good mechanical properties, no heat treatment hardening phenomenon, and no elasticity.

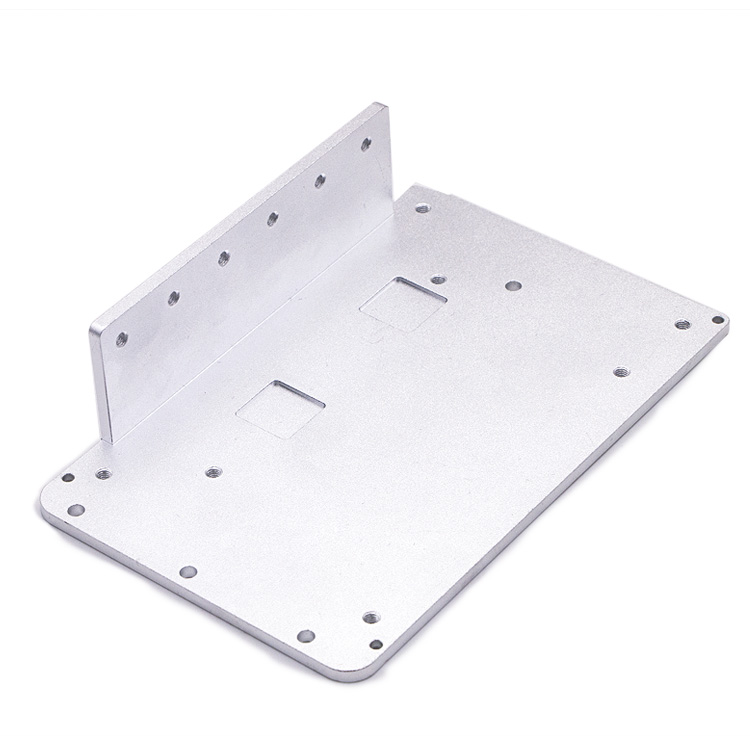

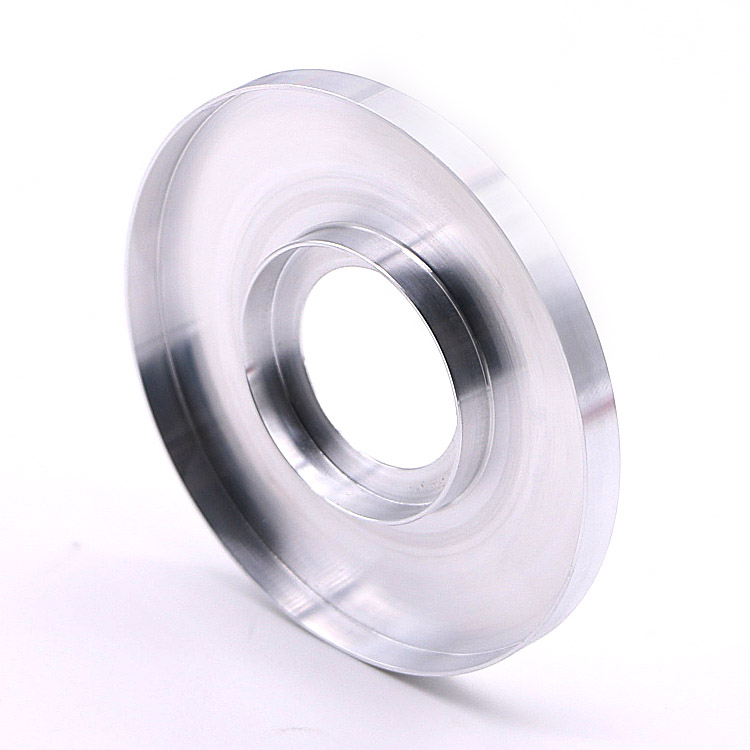

sheet metal fabrication is a kind of iron and steel products processing technology belongs to the cold processing process, and sheet metal fabrication belongs to the iron and steel processing industry, according to the international definition of sheet metal fabrication, sheet metal fabrication is a relatively complete cold processing technology of sheet metal, sheet metal fabrication through cutting plate, cutting plate, splicing and other processes finally forming.

sheet metal fabrication has been widely used in many fields, such as the electronic and communication industry, car industry, and then, the medical machinery, has been widely used, we ordinary people also often used sheet metal fabrication and manufacturing of products, such as TV, mobile phone, refrigerator, computer, electric cooker and so on.

Before the sheet metal fabrication, the staff also needs to know about the range of sheet metal fabrication, generally in the sheet metal fabrication, can choose copper and stainless steel and galvanized sheet materials such as complete machining process, so this way of sheet metal fabrication range is wide, also can meet the production needs of different industries, in sheet metal fabrication technology during the processing, People can choose materials flexibly, do not worry about the material does not meet the processing requirements and affect the progress of the production task.

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.