Sheet metal bending or forming is the process of applying a bend or bend to a sheet of metal by holding it at a point and applying enough pressure to fold the metal.

Sheet metal bending or forming is the process of applying a bend or bend to a sheet of metal by holding it at a point and applying enough pressure to fold the metal. The Angle of bending is usually determined by the shape of the top or bottom tool (usually a "V" shape) and the pressure applied.

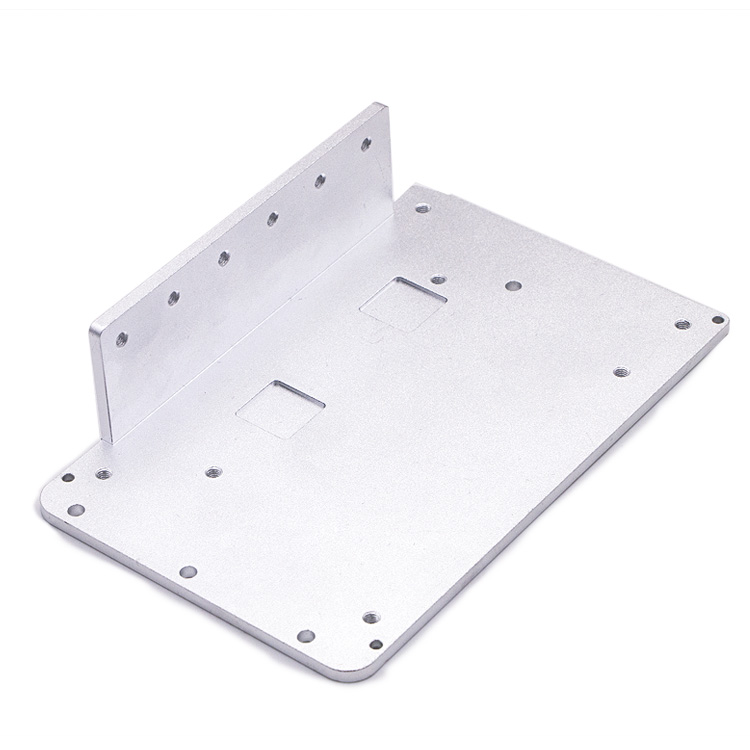

Principle: bending refers to doing in sheet metal pieces of the straight edge, hypotenuse, bending, such as shape, such as metal sheet bending into L, U, V, sheet metal outer layer by the tension in the process of bending, the inner stress, from la to pressure between a neither by pulling force and the transition of the middle, no pressure before the middle in the process of bending and bending length, remain the same. The middle layer is the basic standard for calculating the length of bending parts. The middle position is related to the degree of deformation, when the bending radius is larger, the bending Angle is smaller, the deformation degree is smaller, and the middle position is close to the center of the sheet thickness. When the bending radius becomes smaller and the bending Angle increases, the deformation degree increases, and the middle layer gradually move to the inner side of the bending center.

There are a computer case cabinet, TV backplane, car shell, air conditioner shell, terminal integrated case, charging pile box, and so on.

fast processing speed

Sheet metal processing technology is the most significant advantage of cutting processing speed

Sheet metal processing laser cutting belongs to non-contact cutting, its cutting edge is very little affected by heat

Sheet metal processing can be fast processing of aluminum alloy plate and hard alloy

Seam cutting generally does not require secondary processing, which improves work efficiency to a certain extent

Sheet metal fabrication materials commonly used are cold-rolled sheet (SPCC), hot-rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (CU) brass, red copper, beryllium copper, aluminum plate (6061, 6063, hard aluminum, etc.), aluminum profiles, stainless steel (mirror, drawing surface, fog surface), according to the different role of the product, the selection of materials, Generally, the use and cost of the product should be considered.

1. SPCC cold-rolled sheet, mainly used in electroplating and paint parts, low cost, easy molding, material thickness ≤3.2mm.

2. Hot rolled plate SHCC, material T≥3.0mm, also used electroplating, paint parts, low cost, but difficult to form, mainly used flat parts.

3. Galvanized sheet SECC, SGCC. SECC electrolytic plate N material, P material, N material is not mainly surface treatment, high cost, P material for spraying parts.

4. Copper; Mainly with conductive materials, its surface treatment is nickel plating, chromium plating, or no treatment, high cost.

5. Aluminum plate; General surface chromate (J11-A), oxidation (conductive oxidation, chemical oxidation), high cost, silver plating, nickel plating.

6. Aluminum profile; Materials with complex cross-section structures are widely used in various boxes. Surface treatment with aluminum plate.

7. Stainless steel; Mainly used without any surface treatment, high cost.

1. Electroplating: in an electroplating solution, charged ions are attached to the surface of the product under the action of an electric field to form a coating.

2. Powder spraying: the powder is polarized, under the action of electric field force, evenly attached to the product surface of opposite polarity.

3. Electrophoretic coating: Under the action of the Yin and Yang poles, charged coating ions move to the surface of the product and deposit to form a coating.

4. Dipping: the product is heated in the molten material, and the heated metal is combined with the surrounding molten material to form a surface material of a certain thickness.

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.