Sheet metal bending is a metalworking technique used to change flat sheet metal parts into V, U, or groove shapes.

Three advantages of sheet metal processing

1. Fast processing speed

The most obvious advantage of sheet metal processing technology is fast cutting speed, which will not be limited by the amount of processing. But the processing process is more suitable for processing special-shaped workpieces because it does not waste the tool change time, so as to effectively improve the processing speed; To a certain extent, its machining speed and maximum positioning speed are obviously faster than that of wire cutting.

2, the effect is obvious

Laser cutting in sheet metal processing belongs to non-contact cutting, its cutting edge is less affected by heat and can avoid the adverse effect of thermal deformation of the workpiece. Moreover, it can completely avoid the edge collapse formed when the material is cut and cut, and the cutting seam generally does not need secondary processing, which improves the work efficiency to a certain extent. In addition, its cutting head does not contact the material surface, thus effectively ensuring that the workpiece will not be scratched.

3. Not limited by material properties

Sheet metal processing can quickly process aluminum alloy plate and hard alloy, no matter how high the hardness can be cut without deformation. And its processing flexibility is very good. Not only can it process any kind of figure, but it can also cut pipes and other odd-shaped materials. Moreover, most non-metallic materials can be cut quickly and efficiently, so they are not limited by any material properties.

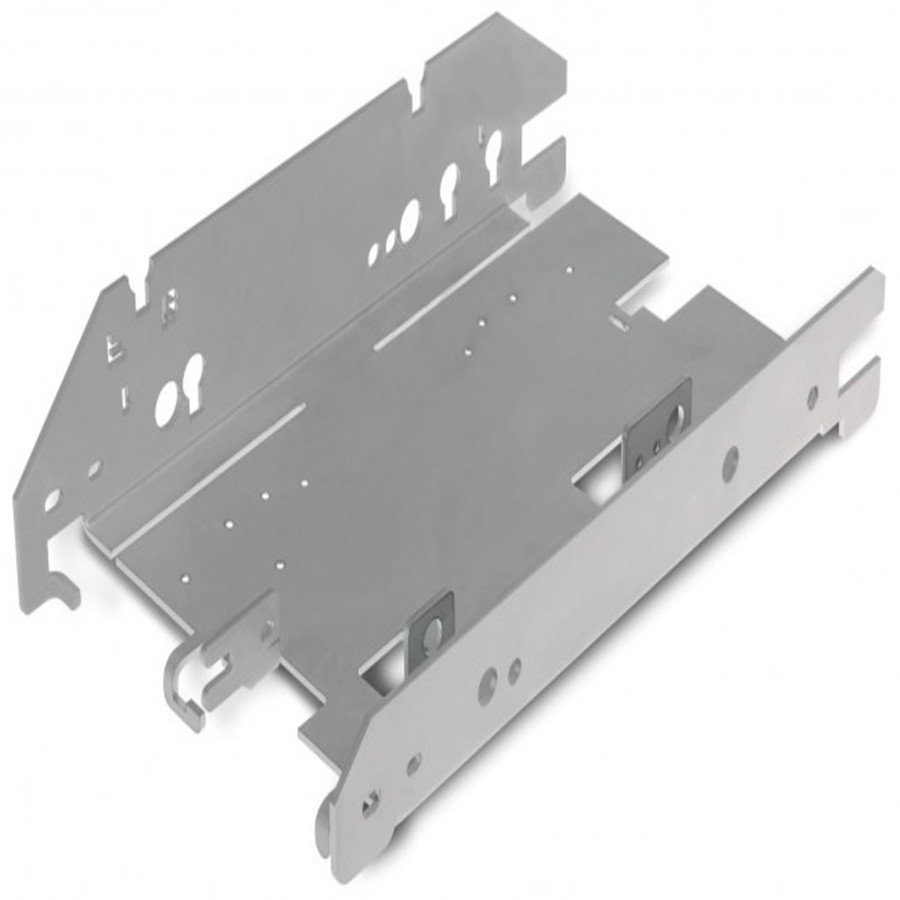

sheet metal fabrication is the processing of metal products, more is to transform the metal plate, to achieve its various uses. There are many processing methods including stamping, cutting, cutting, and so on. Can change the properties and shape of the metal.

Sheet metal products have the characteristics of lightweight, high strength, electric conductivity, low cost, good mass production performance, and so on, have a wide range of uses, sheet metal processing in electronic appliances, communications, automotive industry, medical equipment, and other fields have been widely used, such as in computer cases, mobile phones, MP3, sheet metal is an essential part. It is also used in the manufacturing of medical devices, car and truck bodies, aircraft fuselages and wings, medical tables, building roofs, and many other applications. In short, sheet metal processing has some very wide use, in our production and life brings a lot of conveniences.

The most important sheet metal bending device is the brake, which comes in several different forms:

A cornice brake is a simple bending machine -- and the most widely used brake in manufacturing -- that clamps a metal plate to a flat surface and then uses force to make straight bends or simple creases through the movement of movable bending blades.

A bending machine is a bending machine that uses a moving punch and corresponding die. During this process, the metal plate is placed on the mold and the punch is forced into the metal, forcing it into the mold. Depending on the shape of the mold, you can use a bending machine to make V, U, and other shapes.

Box brakes (also known as finger brakes) are another type of bending machine that uses an array of metal "fingers" to achieve multiple custom bends. As the name suggests, box disc brakes are often used to make custom-sized boxes.

A bar folding machine is a small and simple bending machine with a handle that clamps a metal plate and bends it in a single motion.

Sheet metal bending machine

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.