Customized metal enclosures (customized metal cabinets) are core components that protect precision parts. Their performance is directly dependent on the accuracy of sheet metal bending and welding processes. In this article, we will deeply analyze how sheet metal processing technology can create durable metal enclosures with high strength and high precision, and provide selection guidance for enterprises.

Customized metal enclosures (customized metal cabinets) are core components that protect precision parts. Their performance is directly dependent on the accuracy of sheet metal bending and welding processes. In this article, we will deeply analyze how sheet metal processing technology can create durable metal enclosures with high strength and high precision, and provide selection guidance for enterprises.

About Sheet Metal Fabrication Process

Sheet metal fabrication transforms flat metal sheets into functional components through a series of precise steps. Here's a structured breakdown:

1. Design & Planning

CAD/CAM: Software creates 3D models (CAD) and converts them into machine instructions (CAM).

Tolerances & Allowances: Critical for fit; bend allowance calculated using the K-factor (material-dependent ratio).

2. Cutting Processes

Shearing: Straight cuts using guillotine-like tools.

Laser Cutting: High precision with CO2/fiber lasers (fiber handles reflective metals).

Waterjet Cutting: Uses abrasives for heat-sensitive materials.

Plasma Cutting: Cost-effective for thick metals.

Punching/Blanking: Creates holes (punching) or shapes (blanking) with dies.

Notching: Removes edge sections for fittings.

3. Bending & Forming

Press Brake: Uses punches/dies; accounts for springback (material rebound).

Rolling: Forms curves via three-roller machines.

Stamping: Dies in presses create complex shapes (single/progressive stages).

Deep Drawing: Stretches metal into dies for hollow shapes (e.g., cans).

Hemming/Flanging: Folded edges for safety or attachment.

4. Joining Techniques

Welding: MIG (fast), TIG (precise), Spot (auto panels).

Riveting/Adhesives: Mechanical or chemical bonding.

Fasteners: Screws/bolts for removable parts.

Soldering/Brazing: Low-temp joining (<840°F soldering; >840°F brazing).

5. Finishing

Deburring: Remove sharp edges manually or mechanically.

Surface Treatment: Powder coating (durable), painting, plating (galvanizing, chrome), anodizing (aluminum oxide layer).

Polishing: Aesthetic finish for decorative parts.

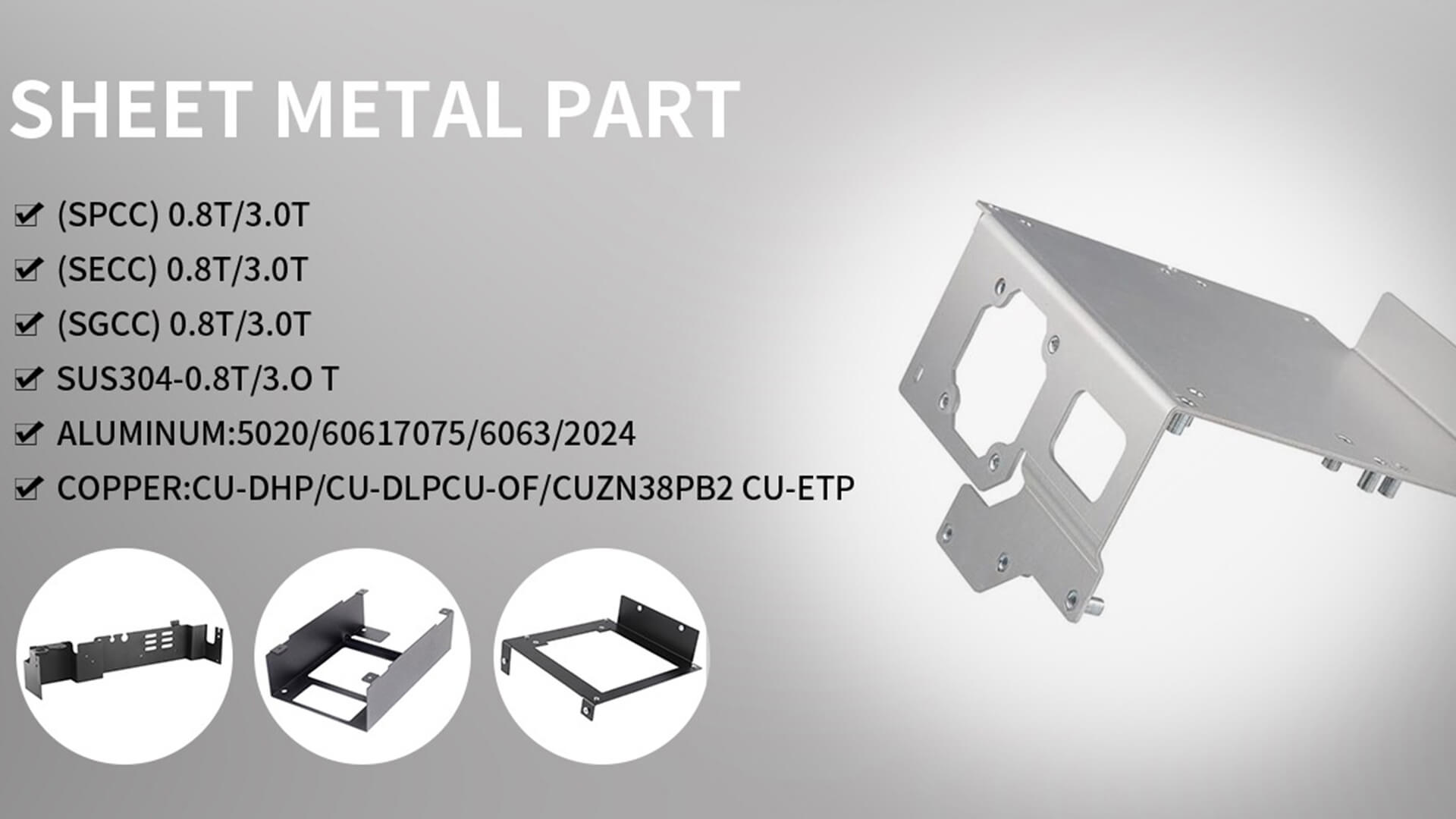

Material selection for custom metal enclosures

Common materials

Stainless steel: Highly corrosion-resistant, suitable for medical equipment, outdoor cabinets (such as NEMA 4X enclosures).

Aluminum: Lightweight and highly thermally conductive, suitable for electronic heat dissipation enclosures (such as 5052 aluminum alloy for IP67 outdoor equipment).

Carbon steel: Low cost, high strength, mostly used in construction and heavy machinery.

Copper/brass: Excellent conductivity, used for electronic component enclosures or decorative parts.

Thickness selection

Material thickness (0.006–0.25 inches) needs to balance strength and machinability. For example, thin sheets (such as 1.5mm aluminum) are easy to bend, but the minimum bend radius must be noted to avoid cracking

Design Principles For Metal Enclosure

Minimum bending radius: usually 1–1.5 times the material thickness, stainless steel requires a larger radius (e.g. R ≥ 2t) to prevent cracks.

Hole and cutout design: hole diameter must be ≥ material thickness to avoid stress concentration (e.g. server chassis hole offset case).

Tolerance control: bending angle tolerance ±1°, laser cutting accuracy can reach ±0.1mm, and ISO 2768 standard must be combined.

Springback compensation: Springback is a common problem in sheet metal bending, which can be solved by die angle compensation (e.g. overbending method) or material pretreatment (e.g. annealing)

Welding technology - Ensures airtightness and durability of metal Enclosure

Sheet metal welding process Introduction

Sheet Metal Welding Types | Used For | Advantages |

TIG welding | Stainless steel/aluminum alloy housing | Beautiful, spatter-free weld seams for precision electronic devices |

Laser cutting welding | Ultra-thin sheet (under 0.5mm) | Small heat affected zone to avoid metal deformation |

Resistance welding | TIG welding | Fast and suitable for standardized metal enclosures |

Surface Finishing of Metal Enclosure

Powder coating: corrosion resistance, various colors, suitable for outdoor cabinets (such as NEMA 4X enclosures).

Anodizing: enhances the wear resistance of aluminum, common in electronic equipment housings.

Electromagnetic shielding finishing: bend seams need to be welded or filled with conductive glue to ensure electromagnetic continuity (such as server chassis)

How to choose a sheet metal Fabrication Service Provider?

Custom metal enclosure selection guide

Customized services and industry experience

Demands vary greatly in different fields, such as medical equipment requires 316L stainless steel and passivation treatment, while outdoor cabinets require powder coating for corrosion protection47. Sheet metal processing service providers should have relevant industry experience. Support ODM/OEM services and provide full process support from design to assembly, such as hinge structure optimization or electromagnetic shielding treatment

Material diversity

High-quality sheet metal processing service providers should provide a variety of material options, such as stainless steel (corrosion resistance), aluminum alloy (lightweight), galvanized steel (economical), etc., and can recommend suitable materials according to the application scenario19.

Design for manufacturability (DFM) support

Sheet metal processing service providers need to participate in design optimization, such as adjusting the bending radius (at least 1-1.5 times the material thickness), hole layout (to avoid stress concentration) and tolerance control (such as ±0.1mm) to reduce production risks

Equipped with advanced processing equipment

Preferably choose sheet metal processing service providers equipped with high-precision CNC equipment (such as laser cutting machines, CNC bending machines, and punching machines) to ensure the efficient implementation of complex designs. For example, laser cutting accuracy can reach ±0.1mm, which is suitable for precise heat dissipation holes or complex contours

Quality control and certification system

The sheet metal processing service provider you choose should be equipped with tools such as three-dimensional coordinate measuring machine (CMM), hardness tester, etc., and follow international certifications such as ISO 2768 (tolerance standard) and ISO 9001 (quality management)

Recommended Custom Metal Enclosure Manufacturer

The sheet metal bending process directly determines the reliability and market competitiveness of the product by affecting the strength, precision, surface quality and functionality of the metal housing. The housing performance can be significantly improved through scientific material selection, mold optimization, precise parameter control and process sequence planning.

Whether you are a startup that needs a small batch of customized metal housings or a manufacturer pursuing mass production metal housing solutions, Bergek CNC technical engineering experts in sheet metal bending and welding technology will provide you with reliability assurance.

Contact our team of engineers now to get free design and real factory price quotation advice!

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.