The development of the machinery industry has made the sheet metal fabrication industry develop vigorously. There are many mechanical equipment materials with stainless steel sheet metal. For different equipment needs, we want to provide different solutions and create good quality for customers at a low cost. So how is the stainless steel sheet metal fabrication?

The development of the machinery industry has made the sheet metal fabrication industry develop vigorously. There are many mechanical equipment materials with stainless steel sheet metal. For different equipment needs, we want to provide different solutions and create good quality for customers at a low cost. So how is the stainless steel sheet metal fabrication? Today bergek will introduce the process steps of stainless steel sheet metal processing.

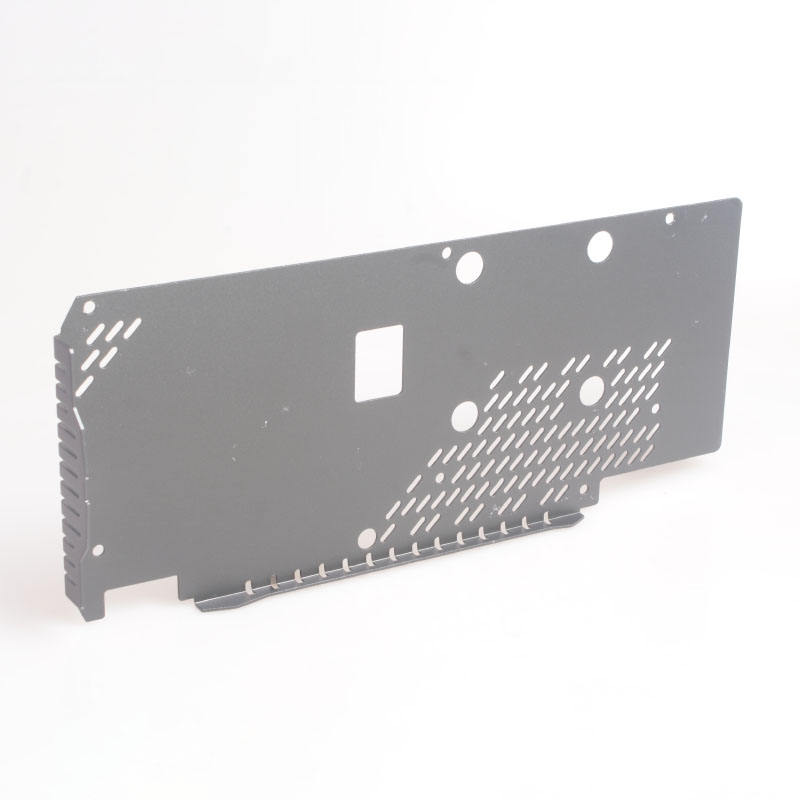

How to process stainless steel sheet metal?

Select the cutting material. When complete, the next process begins. Different stainless steel workpieces will enter the corresponding process according to the processing requirements. Secondly, bending should be determined according to the size of the drawing and the thickness of the stainless steel material bending tool and knife slot. The key to selecting the upper die is to prevent deformation caused by the collision between the material and the tool, which is determined according to the thickness of the stainless steel plate. Pressure riveting to consider the height of the stud, choose the appropriate mold, and then adjust the pressure of the press, in order to ensure that the bolted column and the workpiece surface flush, avoid the stud pressure not firm or pressure out of the workpiece surface, resulting in a scrap of the workpiece. Welding includes argon arc welding, spot welding, carbon dioxide gas-shielded welding, and manual arc welding. The welding position of the workpiece should be considered when spot welding, stainless steel plate batch processing should be made positioning tooling, to ensure accurate spot welding position.

In order to ensure solid welding, it is necessary to hit a convex point on the welder, so that the convex point is in contact with the stainless steel plate before electric welding, to ensure that each point heating is uniform, and can determine the welding position. In addition, in the welding process, should adjust the preload time, heat preservation time, and rest time, are to ensure that the workpiece spot welding firm.

2. The surface of the stainless steel sheet metal workpiece after bending riveting needs to be treated, and the treatment method for different plate surfaces are different. Stainless steel cold plate surface is usually processed after plating, plating is not sprayed, but the use of phosphating treatment, phosphating treatment needs to be sprayed. After the surface is cleaned and degreased, the plating plate is sprayed.

3. After the surface pretreatment of stainless steel sheet metal, a spraying process is required. When the workpiece needs spraying after assembly, the conductive hole and other parts of the tooth hole should be protected. A soft glue rod or screw can be inserted into the tooth hole. High-temperature tape should be pasted on the parts that need conductive protection, and a large number of positioning tools should be made for positioning protection so that the spraying will not spray into the workpiece. On the outer surface of the stainless steel workpiece, the hole of the nut flanging can be seen to be protected by the screw, so as to avoid the hole of the nut 40 flanging 41 after spraying.

4. Start the assembly process after spraying. Before assembly, the protective stickers used in the original stainless steel spraying should be removed to ensure that no paint or powder is sprayed in the inner threaded holes of the parts. During the whole process, gloves should be worn to prevent dust from splashing on the workpiece, and part of the workpiece should be cleaned by purging. After assembly, the packaging process begins. After inspection, put the workpiece into a special bag for protection. Some parts without special packaging are packed with bubble wrap. Before packaging, the bubble film should be cut into a large size that can be used for packaging the workpiece, so as not to package one side, and affect the processing speed; After packaging, you can customize a large number of stainless steel special cartons or bubble bags, rubber pads, trays, wooden cases, etc., put them into the carton, and then stick the labels of finished products or semi-finished products on the carton.

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.