For any structural part, it has a certain processing process. First the sheet metal fabrication plant parts design and draw drawings, the structure of the expression; Then the complex structure of the parts into a shape and easy to process the hole of the workpiece. Next to the processing link, according to the differences in sheet metal parts structure, the sheet metal process is different, summarize the following points.

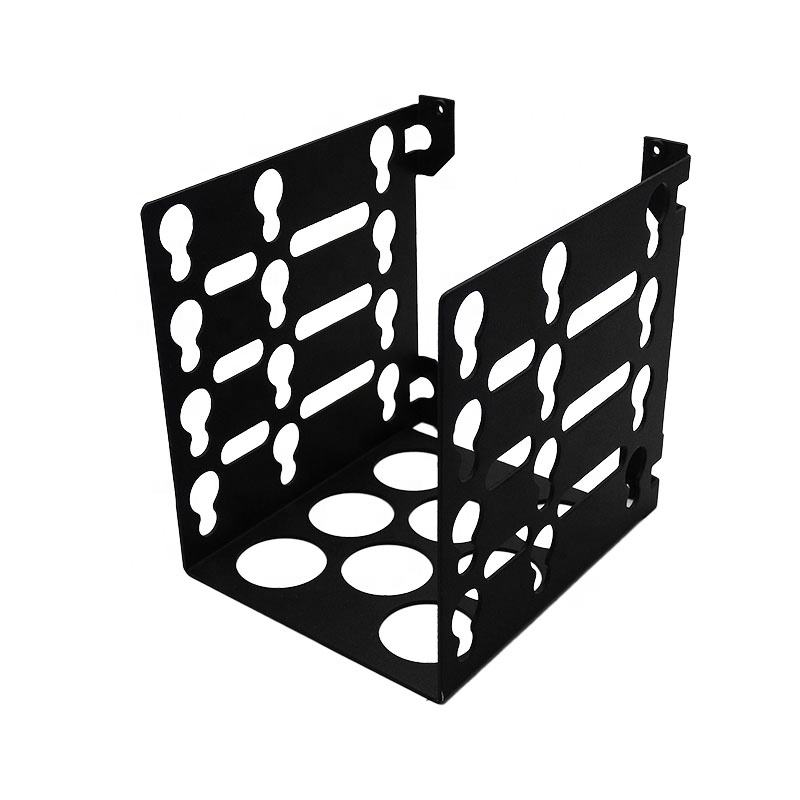

Our metal bending company specializes in precision sheet metal fabrication. With a focus on core attributes such as accuracy and quality, we offer services that include blanking, flanging, pressure riveting, bending, welding, surface treatment, and assembly. Our value attributes lie in our ability to cater to different sheet metal parts structures and provide customized solutions for various material requirements. Trust our expertise in metal bending services to deliver top-notch products with strong structural integrity.

At our Metal Bending Services, our team strength lies in our precision sheet metal fabrication capabilities. With a highly skilled team of experienced technicians and engineers, we are dedicated to providing top-quality metal bending services that meet and exceed our customers' expectations. Our team's expertise, attention to detail, and innovative approach ensure that every project is completed with precision and efficiency. With a focus on teamwork and collaboration, we are able to deliver exceptional results while maintaining a high level of customer satisfaction. Trust our team to handle all your sheet metal fabrication needs with professionalism and expertise.

Our team of skilled craftsmen at Metal Bending Services is the backbone of our precision sheet metal fabrication business. With years of experience and dedication to quality, our team ensures that each product we create meets the highest standards of accuracy and durability. From our expert welders to our detail-oriented engineers, every member of our team plays a crucial role in delivering top-notch metal bending services to our customers. Our collaborative approach and strong communication skills guarantee that we work seamlessly together to provide you with the best possible results. Trust in our team's strength to bring your metal fabrication projects to life.

For any structural part, it has a certain processing process. First the sheet metal fabrication plant parts design and draw drawings, the structure of the expression; Then the complex structure of the parts into a shape and easy to process the hole of the workpiece. Next to the processing link, according to the differences in sheet metal parts structure, the sheet metal process is different, summarize the following points.

1. Blanking. There are many ways of blanking, mainly the following four ways: cutting bed blanking. It is the use of a cutting machine to cut out the length and width of the outline of the diagram. Only the maximum size of the workpiece can be cut out; Punch blanking. Is the use of punch to its shape and hole processing, mass production punch blanking has more advantages;

There are two kinds of CNC blanking, the workpiece made of high precision: CNC number punching blanking and laser blanking. The former is more suitable for the sheet under a 3.0mm plate, the latter is suitable for a more complex structure of the workpiece and a thicker sheet workpiece

2. Flanging. Flanging is also called turning hole, hole extraction is to draw a specified size hole on the pre-punching, the sheet metal process can make the workpiece tapping teeth more strength, suitable for the thickness of the plate below 1.5mm workpiece

3. Pressure riveting. Pressure riveting commonly uses studs, nuts, screws, etc., pressure riveting can be riveted to the sheet metal parts through the punch or pressure riveting machine.

4. Bending. Bending is to strengthen the strength of the workpiece. Its processing needs a folding bed and related bending die to complete.

5. Welding. Welding is welding 2 or more 2 parts together to achieve the purpose of processing, Or the edge seam of a single part should be welded to increase the strength of the hem. Its processing types are two-protection welding, argon arc welding, electric welding, robot welding, and collision welding, etc.

6. Surface treatment. Surface treatment has phosphating film, electroplating colorful zinc, chromate, paint, oxidation, etc. Phosphating film is suitable for cold-rolled plates and electrolytic plates; Electroplating colorful zinc is generally used for the surface treatment of cold-rolled plates and machined parts; Chromate, oxidation is generally used for the surface treatment of aluminum and aluminum profiles; The specific surface treatment is based on customer material requirements.

7. Assembly: It is to put multiple parts or components together according to the requirements of the drawing to make it into a complete part. The assembled parts may be finished or semi-finished

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.