Sheet metal bending is the metal plate through the pressure equipment and special mold, the flat sheet into a three-dimensional processing process called bending. Due to different materials, thickness, length, the width of the plate, and the shape of different shapes and angles, so there are different tonnage and sizes of the bending machine pressure equipment, with different heights, shapes, and V amplitude sizes of the upper and lower die with its special shape of the special mold.

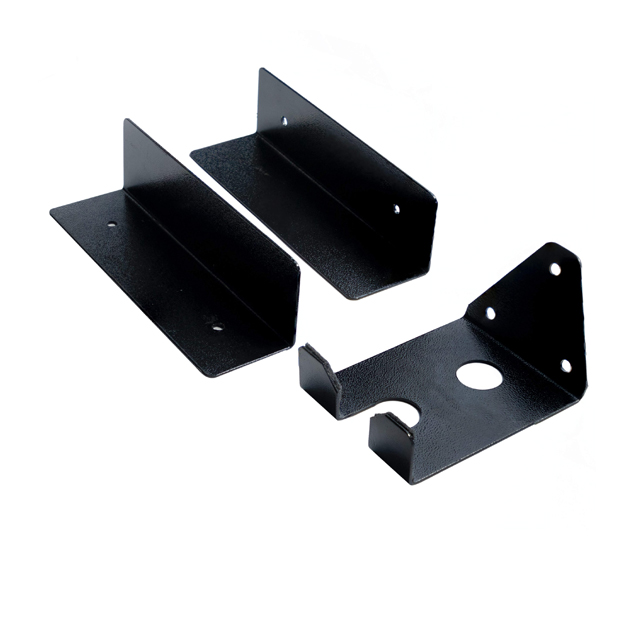

Our precision sheet metal bending services offer high-quality, accurate, and durable products that are created through the use of specialized pressure equipment and molds. With the ability to bend flat sheets into three-dimensional shapes, our services cater to different materials, thicknesses, lengths, and widths, ensuring a wide range of applications. From partial bending to dense bending and embossing bending, our versatile bending capabilities provide precise and reliable results, making them suitable for various industries and product types.

At Precision Sheet Metal, our team strength lies in our exceptional expertise and experience in providing high-quality bending services. Our dedicated team of skilled professionals brings a wealth of knowledge and technical proficiency to ensure precise and accurate bending of sheet metal materials. With a keen attention to detail and a commitment to customer satisfaction, our team takes pride in delivering superior results on every project. Through collaborative teamwork and effective communication, we streamline the production process and meet tight deadlines without compromising on quality. Trust in our team's strength to provide reliable and efficient sheet metal bending services for your business needs.

At Precision Sheet Metal Bending Services, our team strength lies in our highly skilled and experienced staff who are dedicated to delivering top-quality products. Our team of metal bending experts are trained in the latest techniques and equipment to ensure precise and accurate bending for all our customers' needs. Our collaborative approach ensures that every project benefits from the collective experience and expertise of our team, resulting in superior outcomes. With a focus on attention to detail and a commitment to customer satisfaction, our team's strength lies in their ability to consistently deliver exceptional results. Trust in our team for all your precision sheet metal bending needs.

Sheet metal bending is the metal plate through the pressure equipment and special mold, the flat sheet into a three-dimensional processing process called bending. Due to different materials, thickness, length, the width of the plate, and the shape of different shapes and angles, so there are different tonnage and sizes of the bending machine pressure equipment, with different heights, shapes, and V amplitude sizes of the upper and lower die with its special shape of the special mold.

Bending processing is divided into three categories: partial bending, dense bending, and embossing bending.

Part of the bending is 88 degrees; The following upper die, V= 12T (V represents the width of the slot, T represents the thickness of the material) of the lower die for right Angle, obtuse bending method. Close bending is 90 degrees; On the Right Angle and the obtuse bending method. Close bending selection V=6~ 12T. Embossing bending is 90 degrees; The upper die for right-angle bending. (is a standard right-angle bending) embossing bending die selection V=5~ 6T.

At present, there are many kinds of bending machines for sheet metal processing, which can be divided into mechanical (servo motor) and hydraulic types according to the way of rotation. The control system can be divided into simple manual bending machines, ordinary domestic digital positioning bending machines, and process control digital full-function bending machines. According to the action, the part can be divided into 4 axes, 8 axes, and 12 axes bending machines.

Sheet metal fabrication as the name implies is to uses sheet metal processing according to the demand to do needed items. There are a computer case cabinet, TV backplane, car shell, air conditioner shell, terminal integrated case, charging pile box, and so on.

1. Blanking:

There are a variety of blanking methods, refer to the workpiece after laser cutting or CNC punch cutting, shearing machine process. CNC blanking and laser cutting blanking can be used for thick and complex plate workpieces; the Shearing machine can be cut out of the larger shape of the workpiece length and width size; the Punch press can batch use punch press will workpiece shape and hole processing.

2, smoke hole

Hole pumping also called flanging, refers to the use of a die in the ordinary press or other stamping equipment on the workpiece to form a round hole edge up the process. Is in the pre-punch hole into a specified size the hole, so that the workpiece can tap teeth with more strength, generally used in the thickness of 1.5mm plate on the workpiece.

3, pressure riveting

Generally refers to the use of punch or hydraulic riveting machine riveting studs, riveting nuts, riveting screws, and other firmly riveting pressure on the workpiece process.

4, bending

Bending is the process of forming the workpiece by the bending machine with the bending bed and the related bending mold, which can strengthen the strength of the workpiece.

5, welding

Common welding processing types are two protection welding, argon arc welding, electric welding, robot welding, touch welding, etc., the process is mainly to two or more two parts together, to achieve the purpose of finished products or assembly accessories processing; Or the edge seam of a single part needs to be welded so that the bending edge is precise to increase the strength of the folding.

6, surface treatment

The surface treatment has phosphating skin film spraying powder, electroplating colorful zinc, chromate, paint, oxidation, and so on. After phosphating skin film, the workpiece can be electrostatic powder spraying, which is suitable for cold-rolled sheets and galvanized sheets. Electroplating colorful zinc is generally used for surface treatment of cold-rolled plates and machined parts; Chromate and oxidation are generally used for surface treatment of aluminum and aluminum profiles. Surface treatment is to make the sheet metal parts as a whole look beautiful and play a protective role in themselves, the specific surface treatment is based on customer material requirements.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.