Laser cutting is the most widely used laser processing technology in many countries, and in many fields abroad, for example, the automobile manufacturing industry and machine tool manufacturing industry are using laser cutting to process sheet metal parts.

1. Automotive applications

Advanced 3D laser equipment can not only realize the cutting of car body parts but also realize the cutting, welding, heat treatment, cladding, and even 3D measurement of the whole car body, so as to achieve the technical requirements that cannot be achieved by conventional processing.

2. Wide application in the aviation field

Many aero-engine enterprises in the world use 3d laser equipment to cut and punch the superalloy material in the burner section. Laser cutting of aluminum alloy material or special material in military and civil aircraft have been successful.

Laser cutting is the most widely used laser processing technology in many countries, and in many fields abroad, for example, the automobile manufacturing industry and machine tool manufacturing industry are using laser cutting to process sheet metal parts. With the continuous improvement of high power laser beam quality, the laser cutting processing object range will be more extensive, almost including all metal and non-metal materials. For example, the laser can be used for high hardness, high brittleness, and a high melting point of materials for complex shape three-dimensional parts cutting, which is the advantage of laser cutting.

Now, choosing the laser cutting system of the enterprise is mainly divided into two categories: one is large and medium-sized manufacturing enterprises, these enterprises produce a large number of plate products that need blanking, and cutting, and have strong economic and technical strength; Another class collectively referred to as the processing station, specialized external laser processing business, their own no leading products. Its existence on the one hand can meet the needs of some small and medium-sized enterprises processing, on the other hand in the early application of laser cutting technology to promote the role of publicity demonstration.

Several key technologies of laser cutting are integrated technologies of optical, mechanical, and electrical integration. The parameters of the laser beam, the performance, and the precision of the machine and the NUMERICAL control system directly affect the efficiency and quality of laser cutting. The precision, efficiency, and quality of laser cutting are changed by different parameters, such as cutting power, speed, frequency, material thickness, and material, so the rich experience of the operator is particularly important.

(1) good cutting quality: narrow incision width (generally 0.1-0.5mm), high precision (general hole center distance error 0.1-0.4mm, outline size error 0.1-0.5mm), good incision surface roughness (general Ra 12.5 ~ 25μm), slit generally do not need secondary processing can be welded.

(2) cutting speed, such as the use of 2kW laser power, the thickness of 8mm carbon steel cutting speed of 1.6m/min; The thickness of 2mm stainless steel cutting speed of 3.5m/min, small heat-affected zone, minimal deformation.

(3) Clean, safe, and pollution-free, greatly improving the working environment of operators.

Laser cutting belongs to non-contact optical thermal processing, known as the "never wear tool". The workpiece can be arranged or cut tightly in any form to make full use of raw materials. Due to non-contact machining, the distortion of machined parts is minimized and the amount of wear is reduced.

In fact, laser cutting also has its shortcomings, in terms of precision and incision surface roughness, laser cutting failed to exceed the electrical processing, and in terms of cutting thickness is difficult to reach the flame and plasma cutting level. In addition, it can not be shaped like a turret punch, tapping, and folding.

Previously, the sheet metal processing industry uses the traditional punch press for stamping, which later developed into CNC turret punch and compound machine tools. With social progress, laser cutting technology has also been introduced to the metal processing industry and has become a rapid development of industrial plate cutting, a widely used advanced processing method. According to informal statistics, the total number of laser cutting systems used in industrial production in China has exceeded 500, accounting for about 2% of the total number of operating systems in the world.

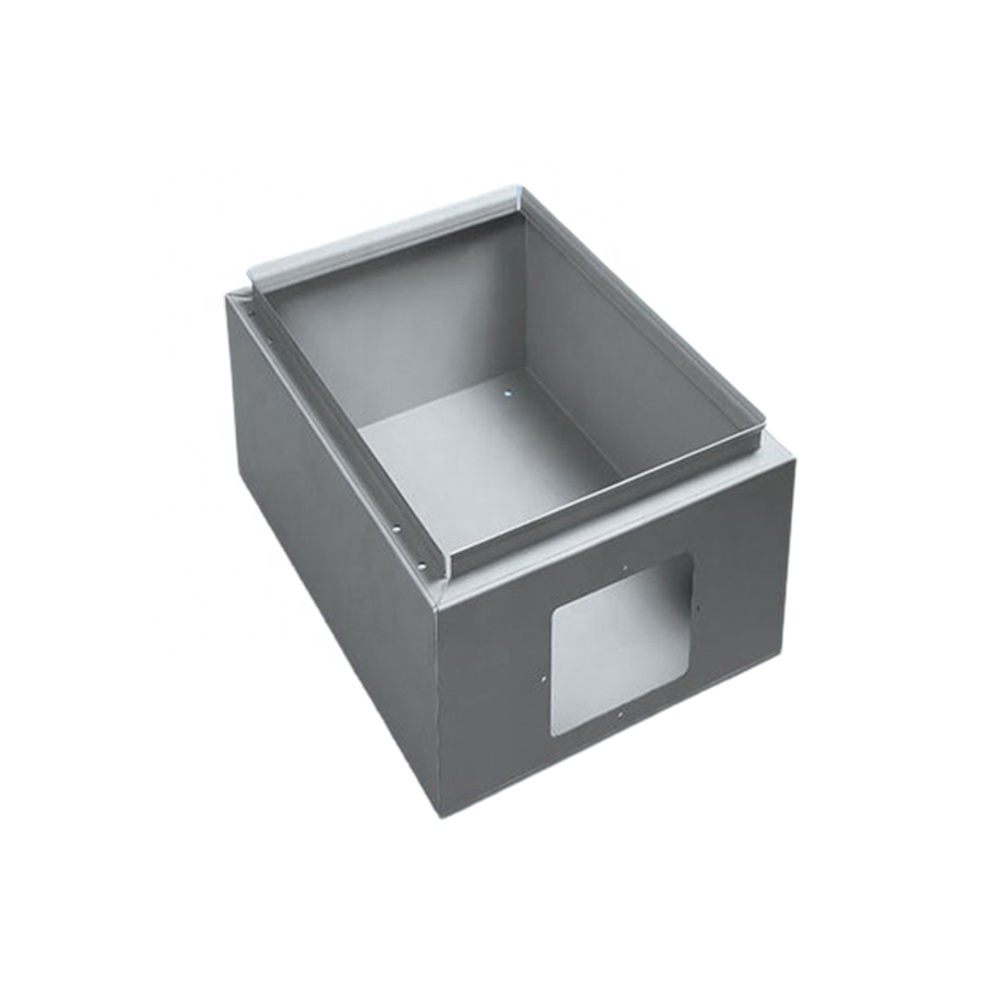

In the metal processing industry, laser cutting is widely used in the thickness of not more than 20mm low carbon steel and 8mm stainless steel, Most the sheet metal parts are complex in shape and small in quantity, such as automatic elevator structural parts, elevator panel, machine tool and food machinery outer cover, various electrical cabinets, switch cabinets, textile machinery parts, construction machinery structural parts, large motor silicon steel sheet, etc. In addition, some decoration, advertising, and service industry with metal patterns, logos, and fonts can also use laser cutting manufacturing.

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.