Picking the right material for your CNC machining project can feel like navigating a minefield, right? One wrong move, and boom - wasted time and money. But don't worry, we've got you covered. This guide will walk you through everything you need to know to choose the perfect material, every single time.

CNC machining can produce parts from almost any metal or plastic. As such, the range of materials from which parts can be produced via CNC milling and turning is vast, and CNC machining offers a wide variety of materials. Whether you are thinking about metal, plastic, wood, or foam, it is important to understand the benefits and best uses for each available material. One wrong move, and boom - wasted time and money. But don't worry, we've got you covered. This guide will walk you through everything you need to know to choose the perfect material, every single time.

Factors To Consider When Choosing CNC Machining Materials

Choosing the right material for your CNC machining project is critical to its success. It's a careful evaluation where several factors must be balanced to achieve the desired outcome. Each material possesses unique properties that make it suitable for specific applications. To ensure optimal results, consider the following key factors:

Product Usage

While getting the product requirements from customers, ask them where the product will be used. Inquire about the environment in which the part will operate or function. Every material has different properties and is used for dedicated applications. So, according to part application, materials with the most suited physical and chemical properties are chosen.

Dimensional Tolerances

Select such a material that offers excellent formability and easy fabrication. Because more machinability a material provides, it is easier to attain tight tolerances requirements.

Tolerance requirements depend on the particular industry as every sector demands different tolerances. For example, the aerospace and medical sectors demand ultra-high precision parts manufacturing. Thus they require greater dimensional tolerances.Choosing materials with precise dimensional tolerances is paramount for high precision, cost-effectiveness, and flawless and on-time project completion.

Stress Load

Stress load means how robust the part should be. It is estimated according to the product application. Once you evaluate the load stress, select a material whose load-bearing capability matches the best. Stress load needs to be calculated carefully. It might be critical in some industries.

Material Cost

Cost is the major factor affecting the whole CNC machining material selection process. Consider that material whose attributes are commensurate the most with requirements. But on the other hand, it should be a cost-effective or cheaper one.

Material Availability

Availability of the material is a big problem when you come to know in the middle of a mass-production project, especially when the material is exhausted and no anymore in stock. The procurement department should ensure availability before finalizing all the project details.

Popular CNC Machining Materials and Their Properties

Now that you know what to consider, let's explore some popular CNC machining materials and their unique characteristics. Think of this as your cheat sheet for finding the perfect match for your project:

Metals:

1.Aluminum

Lightweight, corrosion-resistant, and easy to machine, aluminum is a versatile choice for various applications. It's often used in aerospace, automotive, and consumer goods. Think lightweight bike frames or sleek electronic enclosures.

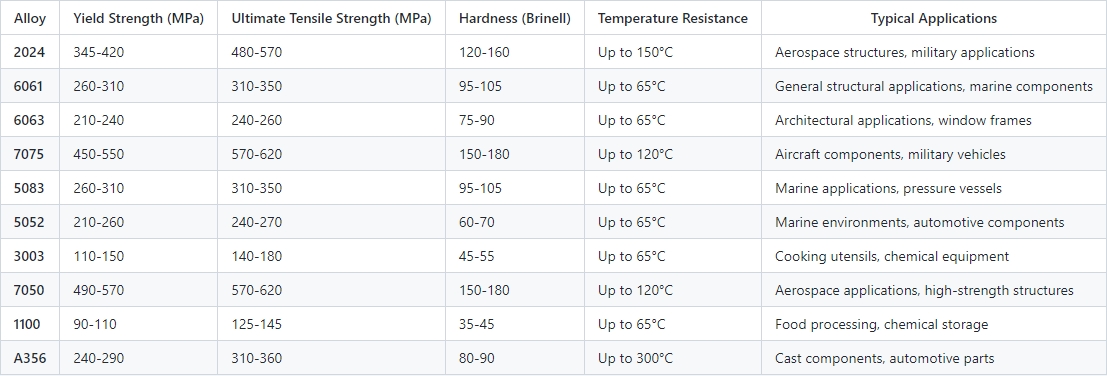

There are several material grades of aluminum, but not all are ideal for use in CNC machining parts and products. That notwithstanding, aluminum grades like 6061 and 7075 aluminum are highly machinable and often used in the production parts where weight is a consideration, such as automotive engine parts and aerospace frames. These categories of aluminum also find application in consumer electronics, construction, and the medical industry. Let's break down the different types of aluminum alloys:

● Aluminum 6061 is the most common, general-use aluminum alloy, with a good strength-to-weight ratio and excellent machinability.

● Aluminum 6082 has a similar composition and material properties to 6061. It’s more commonly used in Europe (as it complies with British Standards).

● Aluminum 7075 is the alloy most commonly used in aerospace applications where weight reduction is critical. It has excellent fatigue properties and can be heat treated to high strength and hardness, making it comparable to steels.

● Aluminum 5083 has higher strength than most other aluminum alloys and exceptional resistance to seawater. This makes it optimal for construction and marine applications. It’s also an excellent choice for welding.

2. Stainless Steel

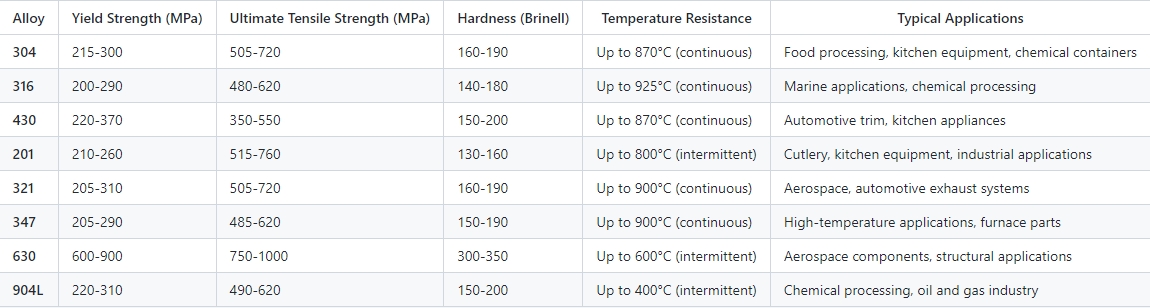

With excellent corrosion resistance, stainless steel is perfect for harsh environments and applications requiring hygiene. It's a popular choice for medical devices, food processing equipment, and marine components. Picture surgical instruments or durable kitchenware.

● Stainless steel 304 is the most common stainless steel alloy. It has excellent mechanical properties and good machinability. It's resistant to most environmental conditions and corrosive media.

● Stainless steel 316 is another common stainless steel alloy with similar mechanical properties to 304. It has a higher corrosion and chemical resistance though, especially to saline solutions (for example seawater), so it's often better for dealing with harsher environments.

● Stainless steel 2205 Duplex has the highest strength (twice that of common stainless steel alloys) and excellent resistance to corrosion. It's used in extreme environments, with many applications in Oil & Gas.

● Stainless steel 303 has excellent toughness, but lower corrosion resistance compared to 304. Due to its excellent machinability, it's often used in high-volume applications, such as producing nuts and bolts for aerospace.

● Stainless steel 17-4 (SAE grade 630) has mechanical properties comparable to 304. It can be precipitation hardened to a very high degree (comparable to tool steels) and has excellent chemical resistance, making it suitable for very high-performance applications, such as manufacturing blades for wind turbines.

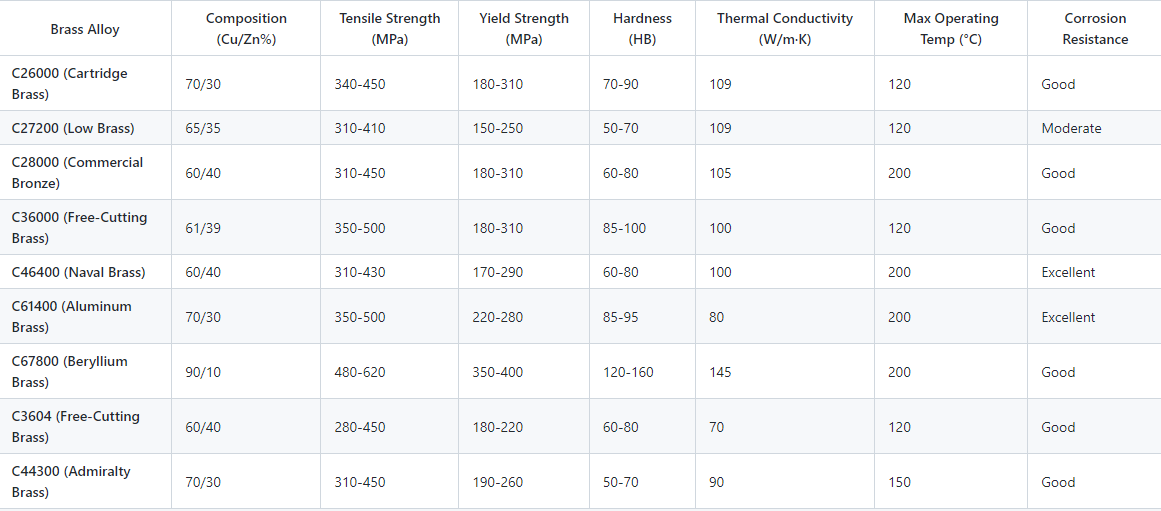

3. Brass

Brass is an alloy of copper and zinc known for its corrosion resistance, excellent electrical conductivity, and machinability. It frequently appears in consumer goods, low-strength fasteners, plumbing, and electrical equipment. Offering a balance of strength, machinability, and aesthetic appeal, brass is often used for decorative components, fittings, and musical instruments. Think intricate door handles or shiny trumpet valves.

Brass C36000 is a material with high tensile strength and natural corrosion resistance. It's one of the most easily machinable materials, so it's often used for high-volume applications.

Material characteristics:

Typical density: 8.4-8.7 g/cm3

Non-magnetic

4. Titanium

Lightweight yet incredibly strong, titanium is often used in aerospace, medical implants, and high-performance applications. Think aircraft components or durable hip replacements.

Titanium has a high strength-to-weight ratio. In other words, aside from being extremely strong, it is also lightweight. Along with having strong heat conductivity, they are also resistant to corrosion. Furthermore, because titanium is biocompatible, it finds use in the biomedical industry.

What's more, titanium finds application in producing high-performance machined parts for several industries, including military, aerospace, and medical. Titanium also finds use as a CNC machine tools material.

Plastics:

1. ABS (Acrylonitrile Butadiene Styrene)

A versatile plastic with good impact resistance and dimensional stability, ABS is used in everything from toys and electronics to automotive parts. Think durable LEGO bricks or protective phone cases. Due to its outstanding machinability, tensile strength, impact resistance, and chemical resistance, ABS material is a very affordable plastic material that is suitable for CNC machining. Additionally, it is simple to color, making it perfect for uses where aesthetics is crucial.

2. Polycarbonate

Polycarbonate is an excellent choice for CNC machining due to its combination of strength, transparency, and ease of machining. Known for its strength, transparency, and heat resistance, polycarbonate is used in eyeglasses, safety helmets, and even bulletproof windows. Polycarbonate is softer than some other plastics, making it prone to scratches. Coatings can be applied to enhance scratch resistance.

3. Polyetheretherketone (PEEK)

PEEK material is a high-performance plastic with excellent chemical resistance. This material also has high dimensional stability and mechanical strength. One of its major advantages is its ability to maintain stiffness at high temperatures, which makes it ideal for use in extreme environments.

PEEK finds application in several industries, including aerospace, food and beverage processing, and oil and gas. It is widely used in producing semiconductor components, bushings, seals, bearings, pump and valve components, etc.

Tips For Choosing Material Selection for Your CNC Needs

Some crucial factors need to be taken into account before finalizing your CNC material. Consider them subsequently, and you will reach the most suitable material for your projects.

●Prioritize Product Usage: While getting the product requirements from customers, ask them where the product will be used. Inquire about the environment in which the part will operate or function. Every material has different properties and is used for dedicated applications. So, according to part application, materials with the most suited physical and chemical properties are chosen.

●Consider the Manufacturing Process: Certain materials are more compatible with specific CNC machining processes. For example, some plastics are better suited for milling, while others excel in turning.

●Think Long-Term: Don't just focus on the initial cost of the material. Factor in things like maintenance, durability, and lifespan. Sometimes, spending a bit more upfront can save you a headache (and money!) down the road.

●Don't Be Afraid to Experiment: If you're unsure which material is best, instead of worrying about choosing from the myriad of materials available, you can select common machining materials which top rated engineers identified and conclude that it works well for machining and is widely accepted for such applications. Common metals include brass, copper, stainless steel, and aluminum. Common plastics include PEEK, Acetal, Nylon, ABS, and Polycarbonate.

●Tap into Expert Knowledge: When in doubt, consult with experienced machinists or material suppliers. They can offer valuable insights and recommendations based on your specific project needs.

Common Mistakes to Avoid When Choosing CNC Machining Materials

Even with the best intentions, it's easy to stumble when choosing CNC machining materials. But don't worry, we're here to help you sidestep these common pitfalls:

●Overlooking Material Properties: It's easy to get caught up in cost or aesthetics, but don't forget the fundamentals. Make sure the material's properties align with your project's needs. Strength, durability, and temperature resistance are just a few things to consider.

●Ignoring Tolerances: CNC machining is all about precision. Failing to consider tolerances can lead to parts that don't fit or function correctly. Ouch!

●Underestimating the Importance of Machinability: Some materials are easier to machine than others. Choosing a material that's difficult to work with can increase production time and costs.

●Neglecting Surface Finish Requirements: Need a mirror-like finish? Or a more textured surface? Factor in your desired surface finish when selecting your material. Some materials take to polishing better than others.

●Not Considering the Environment: Will your part be exposed to harsh chemicals or extreme temperatures? Make sure your chosen material can withstand the elements.

Get The Right CNC Machining Material For Your Projects

The right CNC material selection is essential to making a good and desirable part. It is best to consider all the above mentioned factors carefully. If you consider carefully, then you will be able to choose a successful material for your next project. But the most effective and efficient way to make a part with the desired material properties is to contact the best at it. Yes, you can contact BERGEK CNC with confidence.

BERGEK CNC is a world-class provider of CNC Machining, rapid prototyping services. We serve a wide range of industries in different regions around the world. Bergek CNC is here to help you. We can provide 60+ engineering metals and plastics and have well-experienced machinists and engineers who help recommend materials for your project within your budget range.

Have any specific questions about material machining, please feel free to contact us!

Contact Bergek CNC To Discuss CNC Machining Materials

One-Stop CNC Machining Services Provider

FAQ About CNC Machining Material

1. What is the most cost-efficient material for CNC machining?

This depends a lot on the application in question, but overall Aluminum 6061 is the most common and lowest cost metal for CNC machining.

2. What's the best plastic for CNC machining?

POM (Delrin) is the most economical plastic for CNC machining. This is thanks in part to the excellent machinability of thermoplastics.

3. What are the advantages of CNC machining with metals?

Metals are ideal for manufacturing applications that require high strength, hardness and/or reliable resistances to extreme temperatures.

4. What are the advantages of CNC machining with plastics?

While more common in 3D printing, plastics are ideal for CNC machining when you're looking to produce lightweight parts with special material requirements. Plastics are also viable for producing prototypes (especially before you start making larger quantities with injection molding).

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.