Explore automotive sheet metal fabrication, its techniques, materials use and expert tips to choose the most reliable sheet metal fabrication partner.

Speed, accuracy and durability are not just an option in the modern automotive sector: they are the baseline. It could be a lightweight bracket, an impact-resistant frame part, or a made-to-fit battery case in an EV, the correct sheet metal fabrication method can be the difference between a part that functions perfectly and one that collapses prematurely.

That's why in this guide we will talk about how automotive sheet metal fabrication is done, what techniques would give the best possible results, what materials are better than others, and how to select the appropriate manufacturing partner in your next project. If you need practical, real-life information about automotive sheet metal fabrication presented skillfully, you are in the right place.

What Is Automotive Industry Sheet Metal Fabrication?

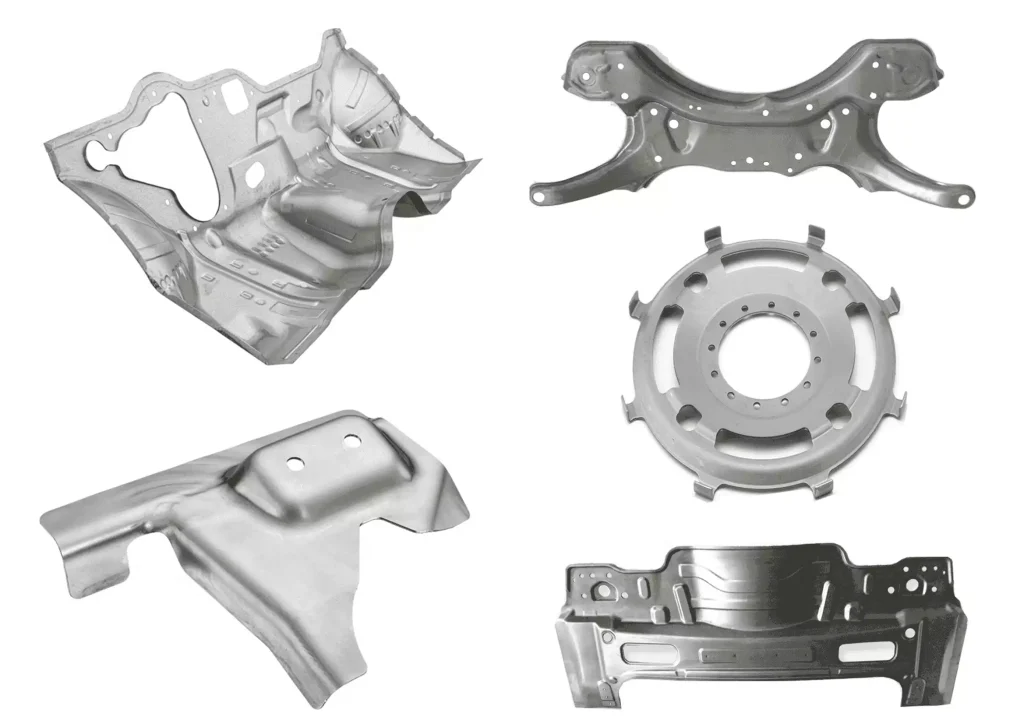

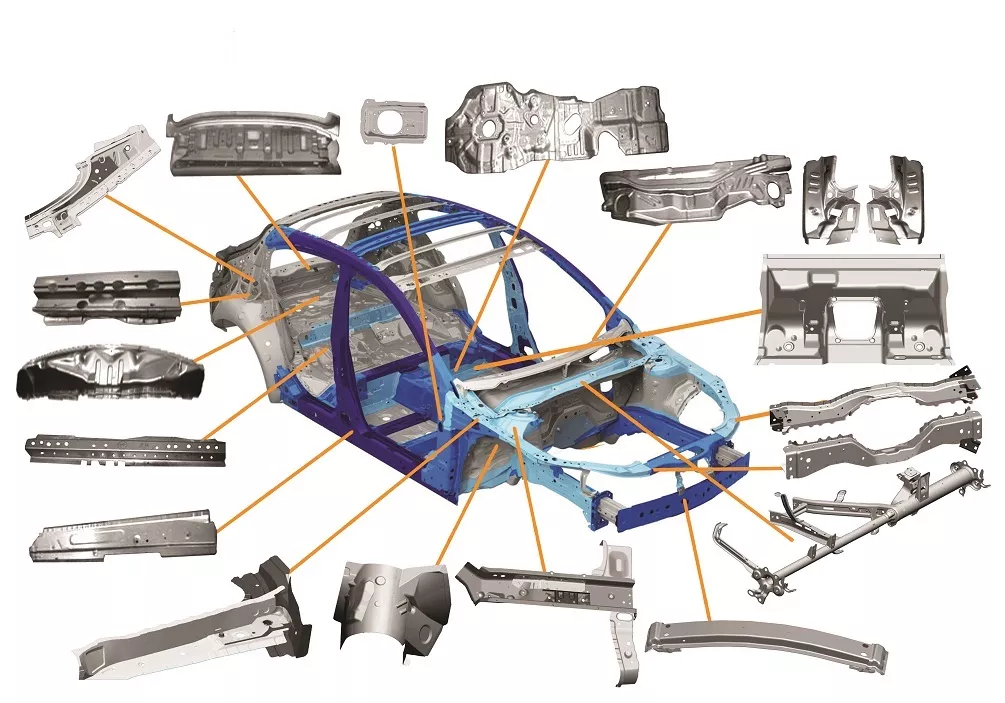

Automotive sheet metal fabrication refers to the full process of cutting, forming, shaping, and assembling metal parts that are utilized in vehicles, from body and exhaust parts to EV battery casing, brackets, and chassis.

The process of automotive sheet metal fabrication is unique since it needs to comply with particular specifications:

● High structural strength

● Excellent crash resistance

● Excellent, consistent dimensional accuracy

● Lightweight performance

● Corrosion resistance

● Compatibility with robotic assembly line

To produce high-quality sheet metal parts that satisfy safety, performance, and aesthetic requirements, modern car manufacturers rely on modern technologies such as laser cutting, CNC machining, stamping and robotic welding.

Which Sheet Metal Techniques Can Be Used for Custom Machining of Automotive Parts?

Automotive applications demand methods that provide accuracy, repeatability and clean edges- particularly in EV parts, brackets, chassis and structural assemblies. The table below talks about 4 of the most popular fabrication technologies.

| Technique | How It Works | Best For | Advantages | Limitations |

| Laser Cutting | Laser beam is used with a high level of accuracy for melting/vaporizing material. | EV battery parts, brackets, aesthetic parts, interior panels. | Very sharp, clean edges, quick cutting, low distortion. | Less efficient with very thick metals. |

| Plasma Cutting | Metal is melted by the high speed ionized plasma jet. | Chassis components, thick steel, reinforced components | It is fast, works with heavy materials, economical. | Rougher edges, more heat-affected zones |

| Waterjet Cutting | Abrasive cut/ high-pressure water, no heat. | Aluminum, composites, delicate or heat-sensitive parts | No heat-affected area, extremely smooth cuts, can adapt to complicated shapes. | Slower than laser/plasma, higher cost |

| Sheet Metal Bending | Sheets are bent to form angles/shapes using press brakes or CNC machines. | Battery trays, frames, housings, structural reinforcements | Highly repeatable, supports mass production, excellent geometric control | Must account for springback and bend radius |

How Do Bending Processes Affect the Manufacturing of Automotive Metal Parts?

One of the most significant processes in fabrication of automotive sheet metal is bending. It has a direct influence on structural integrity, fit and final functionality of a component.

And here's the reason why bending matters so much:

Bending Controls Structural Strength

The improperly performed bend may cause micro-cracks, weaken tensile strength, or cause part distortion. Quality bending is important to keep the reinforcement points structurally sound, important in crash-related components of automobiles.

Accuracy Determines Fit

Even a 1° change in angle can make a whole assembly go off-center. With frequent connections to robotic systems, automotive parts are usually pre-assembled because accurate bending is necessary to ensure a reliable fit.

Reduces Secondary Operations

An excellent and high-quality bend minimizes the rework, welding or cutting.

Critical for EV Components

Precise bends are required in battery trays, brackets and high-voltage housings to ensure safety of enclosures and avoid vibration problems.

Supports Lightweighting Efforts

Premium bending is used to ensure that the strength is retained even in thin and lightweight materials such as aluminum.

In short: Precise bending equals performance, safety, and cost-efficiency.

Which Materials Can Optimize the Performance of Automotive Sheet Metal Parts?

Automotive engineers select materials depending on weight, strength, resistance to corrosion, heat tolerance and cost. The three most popular materials of sheet metal parts are outlined below.

| Material | Performance Benefits | Applications | Why is it used in the Automotive Industry? |

| Stainless Steel | Sturdy, non-corrosive, heat-proof. | Clamps, exhaust systems, trims. | Perfect in high temperature or corrosive conditions. |

| Aluminum | Lightweight, non-corrosive and high conductivity. | EV battery cases, body panels. | Critical in fuel efficiency and lightweighting of the electric vehicles. |

| Titanium | Ultra-strong, lightweight, high-strength-to-weight ratio | Racing parts, high-performance vehicles. | Used in cases when high performance and stability are needed. |

What Quality Standards Are Followed in Automotive Sheet Metal Manufacturing?

The automotive parts should be of high international quality in order to guarantee safety, reliability and durability. Manufacturers normally adhere to:

● ISO 9001: General quality management system.

● IATF 16949: This standard is obligatory for automotive suppliers, and it involves the prevention of defects and process stability.

● ISO 2768 / DIN standards: Dimensional tolerances of mechanical parts.

● ISO 6508 / ISO 6892: Hardness and tensile testing.

● PPAP (Production Part Approval Process): Guarantees standardized production quality.

● APQP (Advanced Product Quality Planning): Intensive planning of high risk parts.

● FMEA (Failure Mode and Effects Analysis): Determines risks before manufacturing.

Adherence to these standards will facilitate the sheet metal fabrication process to manufacture components that meet OEM level expectations.

How to Choose the Right Sheet Metal Fabrication Partner for an Automotive Project

Selecting the wrong partner may result in unstable quality, delays, and time-consuming rework. Here's what to evaluate:

1. Technical Capabilities: Find a partner who works with CNC machining, press brakes, laser cutting, robotic welding, and complete finishing capabilities.

2. Experience with Automotive Projects: You need to ensure your partner is conversant with the IATF 16949 workflows, PPAP requirements and OEM tolerance.

3. Material Expertise: Particularly aluminum and stainless steel when it comes to EV-related parts.

4. Ability to Scale Production: Starting with prototypes, then small batches, then mass production without affecting quality.

5. Transparent Quality and Inspection Processes: CMM measurements, in-process inspections, tensile testing, and material traceability.

6. Engineering Support: DFM (Design for Manufacturability) input is essential in order to eliminate expensive design errors.

BERGEK CNC | Advanced Automotive Sheet Metal Components

BERGEK CNC is a leading manufacturing company that deals with custom-made automotive sheet metal components, providing full support in the process, from prototyping to mass production.

What Makes BERGEK CNC Different?

● High-tech laser cutting, CNC machining, sheet metal bending, and surface finishing.

● Close-tolerance components that are used in OEM automotive processes.

● Familiarity with stainless steel, aluminum, titanium, and special alloys.

● Quick lead times and service of urgent production in the automotive sector.

● In-house quality management in line with ISO/IATF expectations.

● Experience producing components for EVs, fuel systems, body structures, and drivetrain assemblies

You can explore BERGEK CNC's full sheet metal fabrication capabilities here.

FAQs About Automotive Sheet Metal Fabrication

Q1: What is the most commonly used sheet metal in the automotive industry?

Steel and aluminum are the top choices: steel for strength, aluminum for lightweight performance.

Q2: How long does it take to produce custom sheet metal parts?

Prototypes can take a few days, while mass production runs are scheduled weekly or monthly based on volume.

Q3: Can sheet metal fabrication support electric vehicle (EV) components?

Absolutely. EV battery trays, thermal housings, brackets, and shields rely heavily on aluminum and stainless steel fabrication.

Q4: Why is laser cutting preferred for automotive parts?

It offers tight tolerances, excellent edge quality, and minimal distortion, essential for precise fits.

Q5: What finishes are available for automotive sheet metal parts?

Powder coating, anodizing, painting, galvanizing, polishing, and brushed finishes.

Conclusion

Whether you're developing EV housings, structural brackets, or custom prototypes, choosing the right fabrication techniques and partner can dramatically enhance performance, safety, and long-term value.

If you're looking to streamline your automotive project with expert fabrication support, BERGEK CNC offers precision, speed, and engineering reliability you can trust.

Get In Touch With Us!

Copyright © 2026 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.