Mild steel Vs. Stainless Steel. Which one is right for you? Let's find that out in this article, as we explore the key differences between the two.

Fed up with steel components rusting prematurely or bending under stress?

When it comes to metal fabrication, choosing the right type of steel can save you headaches, time, and money. There are some parts that rust out within months and some remain slick and shiny over decades.

The difference? The decision between stainless steel and mild steel.

This is high time we understand the differences between them, why both of them are important for your projects, and how to choose the correct material, particularly when dealing with stainless steel CNC milling parts. By the end of this article, you will understand precisely what kind of steel is needed for every project and why the right or wrong selection can make or break your project, respectively.

What Is Mild Steel?

Mild steel (also known as low-carbon steel) is the workhorse of the metal industry. It is soft, ductile, and simple to shape because it has a small percentage of carbon (usually, 0.05 to 0.25%).

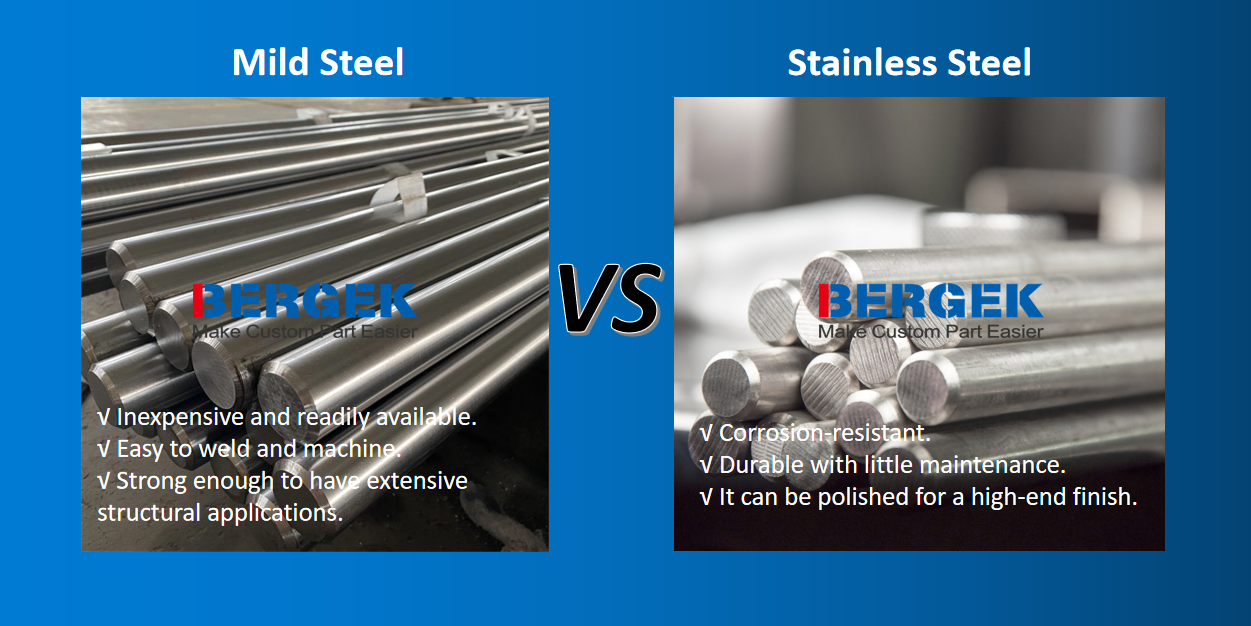

Pros of Mild Steel:

● Inexpensive and readily available.

● Easy to weld and machine.

● Strong enough to have extensive structural applications.

Cons of Mild Steel:

● Without coating, it is prone to rust and corrosion.

● Lower strength than stainless steel in certain applications.

Mild steel is well used in projects where the price matters a lot, and the corrosion resistance is not that important eg, structural frames, car chassis or general machinery.

What Is Stainless Steel?

Stainless steel is an anti-corrosive alloy. It also has chromium (at least 10.5%) that produces a protective oxide coating that makes it shiny and rust-free. When you order stainless steel CNC milling parts, you are generally ordering a material that is strong, durable and attractive.

Pros of Stainless Steel:

● Corrosion-resistant.

● Durable with little maintenance.

● It can be polished for a high-end finish.

Cons of Stainless Steel:

● Costly as compared to mild steel.

● Harder to machine (needs special tools).

The stainless steel is ideal in medical equipment, food processing equipment and automotive parts that require resistance to wear and tear without rusting.

Key Differences Between Mild Steel and Stainless Steel

Let's unpack the main distinctions between mild steel and stainless steel so that you can select the most suitable material to use in your projects, even including high-quality stainless steel CNC milling parts. To simplify the picture, here is a handy comparison table:

| Feature | Mild Steel | Stainless Steel |

| Carbon Content | 0.05–0.25% | Fluctuates (0.03-1%) but contains chromium |

| Corrosion Resistance | Low | High |

| Cost | Low | High |

| Strength | Moderate | High (varies by grade) |

| Machinability | Easy | Harder, might need special equipment |

| Common Applications | Structural frames, automobile components. | Kitchenware, medical equipment, CNC milling components. |

| Maintenance | Needs painting/coating | Minimal, stays shiny naturally |

Both mild and stainless steel offer a set of distinct features, and the decision actually lies in your project requirements: whether you need durability and corrosion resistance, or you want to look at cost efficiency.

Why Material Choice Matters in CNC Milling

When using stainless steel CNC milling parts, the steel type does not simply depend on the price. Mild steel and stainless steel are very different when subjected to cutting tools, which influences their performance in accuracy, tool life, and the end result.

● Tool Wear: Stainless steel is more abrasive and harder and therefore, it can wear down cutting tools at a higher rate. The wrong steel can make it more expensive and time-consuming.

● Precision: Mild steel is easier to machine but can deform with heavy cuts, compromising dimensional accuracy.

● Surface Finish: Stainless steel has a natural glossy finish but a mild steel might require additional finishing.

● Durability: Stainless steel parts are resistant to corrosion, chemicals and high stress levels, so they are suitable for high-stress applications.

Choosing the right material ensures long-lasting, precise, and high-quality CNC milled parts, whether you’re making industrial components or custom stainless steel CNC milling parts.

Common Applications for Mild Steel vs Stainless Steel

It is important to know where each type shines, which can save not only time, but also money and headaches. The most common uses of mild steel and stainless steel are listed below:

Mild Steel:

● Structural frames and supports.

● Chassis and bracket automotive parts.

● Machinery parts where corrosion is not a problem.

● Fencing, gates and general construction.

Stainless Steel:

● Stainless steel CNC milling parts for industrial machinery.

● Cookware and kitchen appliances.

● Medical and laboratory supplies.

● Complex parts and accessories, automotive exhaust systems and trim.

● Chemical processing equipment.

In most business processes, the decision is between performance and cost. For example, automotive manufacturers can use mild steel in their internal structures but use stainless steel in parts that are exposed to heat, moisture, or chemicals. Being aware of this stuff allows you to choose the correct steel for your application, sparing you additional costs and expensive replacements.

How to Identify Which Steel You Need

Choosing the right steel should not overwhelm you. To pick the right steel type for your project, ask yourself a couple of simple questions:

1. Environment: Will the steel be subjected to moisture, chemicals, or outdoor conditions? If yes, then stainless steel is most likely to be the safe choice.

2. Budget: Do you want to save on initial expenses, or want the long run stability? Mild steel is less expensive; however, stainless steel may cost less in terms of maintenance.

3. Machining Needs: Will you be CNC milling, cutting or forging? Mild steel is simpler to machine whereas the stainless steel needs sharper tools and more care.

4. Finish & Appearance: Does your product require any polished and corrosion-free appearance? Stainless steel has a natural shine and does not fade with time.

5. Strength & Load: How much stress or weight will the part endure? Check the mechanical requirements: sometimes stainless steel's higher strength is essential.

When you answer these questions honestly, you can select a steel that most appropriately fits your project, particularly when you are ordering custom CNC milling parts.

Tips for Working with Stainless Steel CNC Milling Parts

Stainless steel has a long lifespan and it is resistant to corrosion, although it is sometimes tricky when it comes to machining. To achieve optimum performance with the stainless steel CNC milling parts, follow the following tips:

1. Use the Right Tools: Stainless steel needs sharp, coated tools to prevent galling.

2. Control Heat: Overheat may harden stainless steel and make it hard to machine.

3. Coolant Is Key: Add enough coolant to minimize friction and increase the life of the tool.

4. Plan Your Cuts: Use lighter passes to be precise and stress-free.

These tips will cost less time and money and will leave your parts with a smooth professional finish.

Cost Considerations: Mild Steel vs Stainless Steel

While the initial cost of stainless steel CNC milling parts may be higher, it will save money in the long-term because it will minimize maintenance and replacement expenses.

● Mild steel is less expensive; however, it might require protective coating or frequent replacements.

● The increased durability of stainless steel can usually compensate the upfront costs.

Conclusion: Making the Right Choice

Ultimately, the decision between mild steel and stainless steel comes down to application, environment, and budget. If corrosion resistance, long-term durability, and aesthetics matter, stainless steel CNC milling parts are the clear winner. If cost is the priority and the part won’t face harsh conditions, mild steel can do the job. Understanding the differences ensures your project runs smoothly, saves money, and results in parts that perform exactly as needed. For high-quality, custom stainless steel CNC milling parts, check out our offerings here.

Get In Touch With Us!

Copyright © 2026 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.