Find out how you can choose the right material for your next sheet metal fabrication parts. Expert tips included!

Choosing the right sheet metal material can make or break your project.

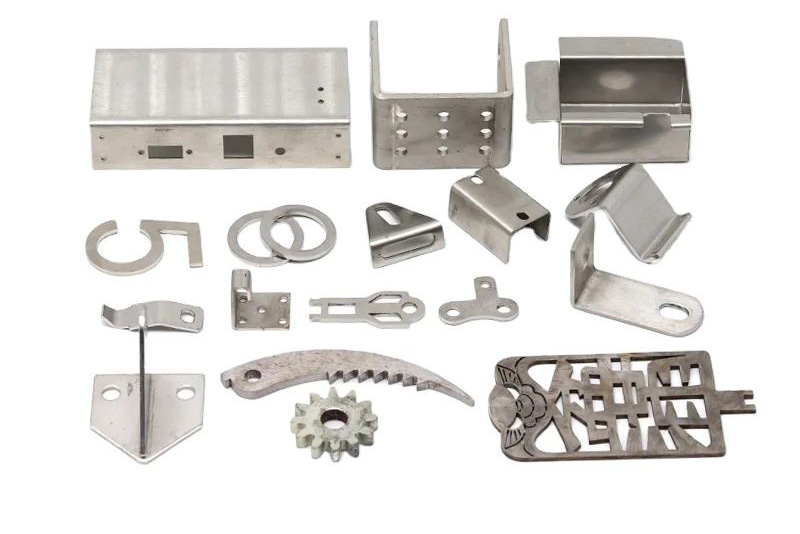

Have you ever wondered why certain sheet metal components have a lifespan of decades and others crumble in a few months? It is nearly always one thing: material selection. Whether it is enclosures, brackets, frames, or any other precision metal part, the right material choice is what makes the difference in terms of durability, manufacturability and cost.

This guide will break down the most popular sheet metal materials, their possible comparison, and what can go wrong if you choose the wrong material. This is your playbook, in case you are in the sheet metal fabrication game. The success of any sheet metal fabrication project is based on the selection of the right material. Every metal has its advantages, peculiarities, and optimal applications. So, it's important to choose the right one.

Stainless Steel: The Tough, Corrosion-Proof Workhorse

Stainless steel is your best choice in case your components need to withstand heat, humidity, impact, or other harsh chemicals.

Why it stands out:

● Extremely durable

● Excellent resistance to corrosion

● Tolerates high temperatures without warping

● Clean, premium finish

Best for: Food equipment, medical devices, outdoor enclosures and structural parts.

Galvanized Steel: Strong, Affordable, Rust-Resistant

Galvanized steel is normal steel but with a layer of zinc: it is that layer that prevents rust.

Why it’s popular:

● Corrosion protection at low cost

● Good structural strength

● Ideal for high-volume production

Best for: HVAC ducts, wall panels, automotive brackets and building frames.

Aluminum: Lightweight, Formable, Built for Speed

In metal fabrications, where weight is a factor, aluminum is the winner. It is easy to bend, quick to machine and it is inherently corrosion resistant.

Why aluminum works so well:

● Strong without being heavy

● Easy to cut, form, and weld

● Excellent thermal and electrical conductivity.

Best for: Electronics housings, aerospace components or consumer products.

Brass: Beautiful, Conductive, and Surprisingly Tough

Brass is a combination of toughness and elegance. Its appearance is like gold which is used in high-quality or decorative components.

Why people choose brass:

● Excellent machinability

● High resilience to corrosion

● Aesthetic, high-end look

● Electrical conductivity is good

Best for: Electrical connectors, luxury hardware or custom fittings.

Factors Important to Sheet Metal Material Selection

Selecting an appropriate sheet metal material is not merely a matter of selecting what is attractive on paper; it has a direct influence on performance, manufacturability, life expectancy, and even overall project cost. These are the most important elements that should be considered before you lock in a material.

Strength of Sheet Metal Parts: Can It Handle the Job?

The strength defines the ability of your part to resist bending, breaking or deforming under the load.

● For high-strength applications, stainless steel or structural-grade steel is the best choice.

● For lightweight strength, aluminum definitely wins.

● For aesthetic and low-stress parts, brass is a go-to option.

If the part holds some weight, supports a load, or is going to be used repeatedly, then strength must be the foremost consideration.

Ductile Strength: Will It Bend Without Cracking?

Ductility refers to the capacity of your metal to stretch or bend during the fabrication process without breaking.

● High ductility (best for complex bends): aluminum, brass

● Moderate ductility: stainless steel

● Lower ductility: some carbon steels

Low ductility may result in cracking during bending, stretching or deep drawing: this translates to waste of material and delay of production.

Corrosion Resistance: Will It Survive the Environment?

The capacity of a metal to endure rust, moisture, and chemical destruction defines the life expectancy of your part.

● For outdoor or marine environments, stainless steel or aluminum should be your choice.

● For cost-effective protection, galvanized steel is best.

● For decorative + corrosion protection, brass stands out here.

Failing to choose a corrosion resistant material can result in early failure, particularly on humid, chemical or other outdoor conditions.

Sheet Metal Material Types and Surface Treatment Processes

Materials act differently in the sheet metal fabrication, and the actual magic occurs when you combine the correct material and the correct surface treatment. The following is a quick reference table illustrating the best treatment of each material.

Making a mistake in the selection of sheet metal material can cause significant issues even before the product gets into the hands of the customer. Find out the most likely (and expensive) consequences of selecting the wrong sheet metal:

Working with materials that cannot withstand moisture, chemicals or other outdoor conditions causes rapid rusting, significantly reducing product life.

When the metal is not strong enough, then parts can bend, crack or deform under load, and this presents safety and reliability problems.

Metals with low-ductility or heat-sensitive properties may crack during the bending process, warp during the welding process, or damage the tools. This slows down the production rate and creates wastage.

Some sheet metals do not do well when certain coatings or finishes are applied. This often results in peeling of paint, unsmooth surfaces or corrosion.

Selecting a cheaper sheet material may sound like a cost saving in the start, but they can frequently result in rework, early failure, warranty claims and unscheduled maintenance.

Companies end up losing thousands of dollars in re-fabrication when the material was not matched to the environment or load conditions. Avoid that trap.

Effective sheet metal parts should offer performance, safety and manufacturability. Here’s what your material must support:

The metal must be able to retain tolerances after bending, punching or welding.

Components should be able to withstand stress, vibrations, weight and pressure without deforming.

Heat causes some metals to expand or warp. Use materials that retain shape within your operating temperature.

Chemicals, moisture, salt or UV exposure should be taken into account.

You don’t need stainless steel for every project. Choose a material that strikes a balance between performance and budget.

If you need to display your product directly to customers, you need materials that must accept the required finish (anodizing, painting, polishing, plating, etc.).

For companies looking for perfection, partnering with an experienced fabricator can make a world of difference.

Choosing the appropriate material to use in your sheet metal fabrication project is not necessarily a technical choice: it is a strategic investment. Knowing about material characteristics, environmental requirements and finishing, you will be able to make stronger, durable, and more cost-effective sheet metal parts.

Having the right material, your components work better, look better and last longer. And when the right manufacturing partner is involved, the process becomes even easier.

Partnering with a professional sheet metal fabrication specialist like Bergek CNC can make a big difference. Their knowledge in materials, precision fabricating and surface treatment will guarantee that their parts comply with the highest standards.

1. Which type of sheet metal is the most durable?

Stainless steel (in particular, 316) is the most durable and corrosion-resistant.

2. What is the best material for lightweight sheet metal parts?

Aluminum is the top choice because it's strong but incredibly light.

3. Can galvanized steel be used outdoors?

Yes, its zinc coating protects it from rust, making it suitable for outdoor applications.

4. Which material is easiest to form or bend?

Aluminum and brass have excellent ductility, making them ideal for complex shapes.

5. Do all sheet metal materials support powder coating?

Most metals can be powder-coated, but aluminum and steel deliver the best results.

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.