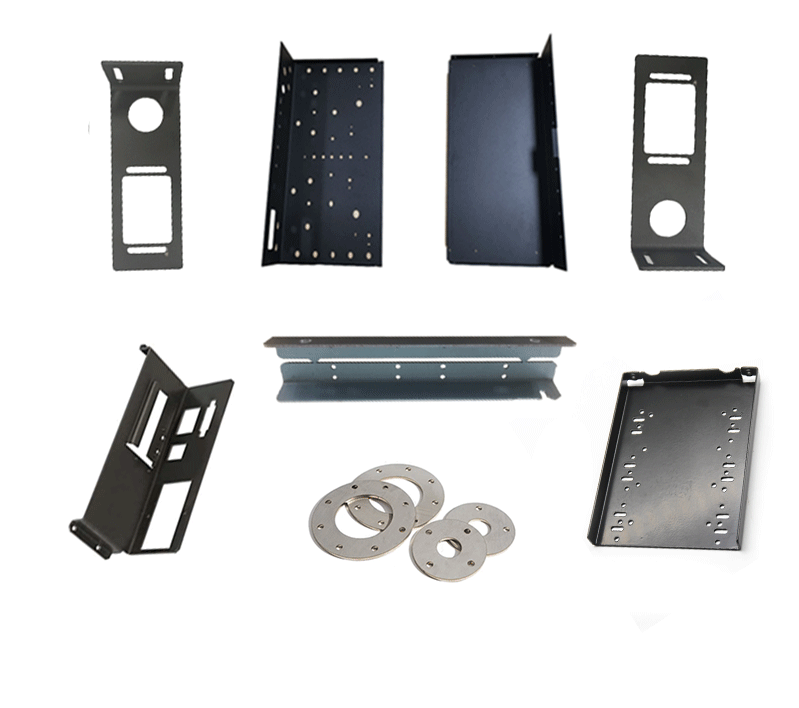

Sheet metal case refers to the case made of special sheet metal materials, which is widely used in the automotive industry, communications, medical devices, electronics, and other fields. But in the process of sheet metal chassis processing, sometimes there will be deformation, what is the cause of this?

Sheet metal case refers to the case made of special sheet metal materials, which is widely used in the automotive industry, communications, medical devices, electronics, and other fields. But in the process of sheet metal chassis processing, sometimes there will be deformation, what is the cause of this?

Causes of sheet metal case deformation:

The main material of sheet metal workpiece is steel. Steel under the rolling line, to the scene of the sheet metal work material, machining, assembly to connect into sheet metal workpiece in the process of the products will be affected by external force and heat deformation processing, etc, and can produce stress and deformation, the deformation of plenty of product technical requirements, have plenty of beyond the technical requirements, the above technical requirements of stress and deformation is called deformation defects.

The deformation of raw materials mainly comes from the rolling process, transportation process, and improper stacking of steel. When steel rolling, if there is plate heat uneven, roll bending, roll gap inconsistency, and other problems, it will make the plate in the width direction of the compression is not uniform. The part with more extension is restrained by the part with less extension and produces compressive stress, while the part with less extension produces tensile stress. Therefore, the part with more extension may be unstable under compressive stress and lead to a sleek shape.

Steel plates, especially thin plates, are easy to produce local concave and convex deformation, crease deformation, or relatively gentle large wave deformation; Large Gongning steel is easy to produce lateral wave shape bending, sometimes distortion. Large channel steel is easy to produce bending deformation; The smaller Angle steel field produces distortion and deformation. After hot rolled steel the process of cooling in the presence of moisture or water will also produce deformation.

Above about deformation of sheet metal chassis processing is what reason is to share here, also because of its unique metal molding process led to the unfavorable has a complicated shape, so in the sheet metal chassis shell design should break through the traditional box model, and to facilitate the manufacturing process, not do more fruitful surface change, suit to do more processing of surface process, reduce the difficulty of production manufacturing Ensure the feasibility of the design scheme at the same time, make the shape of the equipment simple and beautiful, in line with people's aesthetic.

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.