We're explaining the differences between sheet metal fabrication and CNC machining—and why we offer both manufacturing services at BergekCNC

Sheet Metal Fabrication vs CNC Machining

Sheet metal fabrication involves manufacturing parts out of metal. CNC machining involves manufacturing parts out of metal. So aren’t sheet metal fabrication and CNC machining the same thing? We hear this question quite often.

CNC Machining and Sheet Metal Fabrication are two of the most popular manufacturing methods in the industry today. Both offer unique advantages and disadvantages that make them suitable for different applications. Let’s take a closer look at the differences between CNC machining and sheet metal fabrication.

What is CNC Machining:

● CNC machining is a subtractive manufacturing process where material is removed from a solid block using a cutting tool to produce the final shape.

● CNC machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to program the machine and produce the desired part.

● CNC machining can produce very precise parts with tolerances as tight as +/- 0.001 inches.

● CNC machining is suitable for producing complex parts with intricate shapes, sharp corners, and tight tolerances.

At BergekCNC, we machined parts from a variety of materials—not only metal. You'll find us working with aluminum, titanium, steel (including stainless and alloy), plastics, and more. CNC machining allows for precise cutting, shaping, and drilling of various materials such as metal, plastic, wood, or foam.

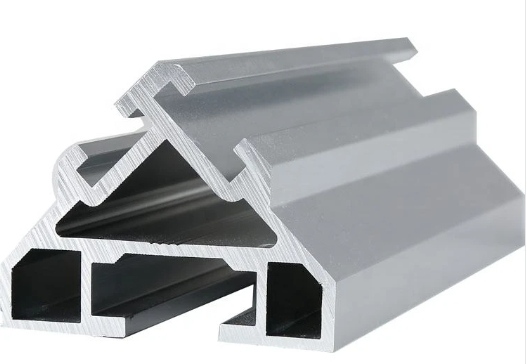

Structural Aluminum Angle、Aluminum 6063 Extrusion、PET、Polypropylene 、PVC

Aluminum Rectangular、Cold Rolled Steel 、Stainless Steel Rectangular

CNC Milling Service

CNC milling is a reduction manufacturing process that uses 3-axis milling and 5-axis indexing to cut solid plastic and metal blocks into final parts. When performing CNC milling operations, we secure a workpiece to a table that moves and rotates on different planes, giving access to the rotary cutting tool.

CNC Turning Service

CNC turning with power tools combines lathe and milling machine functions to process parts with metal bar cylindrical features. Our turning processes include straight and taper turning, spherical generation, grooving, parting, knurling, and threading.

What is Sheet Metal Fabrication:

● Sheet metal fabrication is a manufacturing process that involves forming and shaping flat sheets of metal into the desired shape.

● Sheet metal fabrication can be done using several methods such as cutting, bending, punching, and welding.

● Sheet metal fabrication can produce parts with varying degrees of complexity and precision.

● Sheet metal fabrication is often used for producing large quantities of parts quickly and cost-effectively.

● Sheet metal fabrication is suitable for producing parts with a range of thicknesses.

● We primarily work with sheet metals in gauges ranging from 0.006 to 0.25 with the thinner sheets ideal for high-malleability and the thicker sheets preferred for high-stress applications.

There are several techniques used in sheet metal fabrication, including cutting, bending, and forming.

● Laser Cutting Service: Laser cutting is the most common means of cutting sheet metal. It refers to a manufacturing service that uses high-powered laser beams to precisely cut a variety of materials.

● Sheet Metal Bending Serivce: Sheet metal bending service can achieve bend angles from 0-90 degrees with high precision and accuracy.

● Sheet Metal Stamping Serivce: Sheet metal stamping services include punching, stamping, blanking, embossing, bending, flanging, and coining.

● Sheet Metal Welding service: Sheet metal welding services can handle a wide range of materials including steel, aluminum, brass, copper, and other alloys.

Different Advantages

Advantages of CNC Machining:

● CNC machining offers high precision and accuracy, making it suitable for producing parts with tight tolerances.

● CNC machines can produce parts with complex geometries and shapes that are difficult to achieve with other manufacturing methods.

● CNC machining is ideal for producing low to medium-volume runs of parts.

● CNC machines can work with a wide range of materials, including metals, plastics, and composites.

Advantages of Sheet Metal Fabrication:

● Sheet metal fabrication is a cost-effective method for producing large quantities of parts quickly.

● Sheet metal fabrication can produce parts with varying degrees of complexity and precision.

● Sheet metal fabrication is suitable for producing parts with a range of thicknesses and materials, including steel, aluminum, and copper.

● Sheet metal fabrication can be done using several methods, making it versatile and adaptable to different manufacturing needs.

Get Sheet Metal Fabrication and CNC Machining at BergekCNC!

In business since 2010. we're proud to offer top-quality sheet metal fabrication and CNC machining services under one roof, where you'll always receive personalized attention and service!

Contact us for a custom quote!

1st Floor, Building D, No. 30 Shijing Road, Songgang Lougang Street, Bao'an District, Shenzhen City, Guangdong Province, China

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.