The metal bending process is a fundamental manufacturing technique that involves shaping metal sheets and bars into a desired form. This process is used in a wide range of industries, including construction, aerospace, automotive, and electronics. In this article, we will discuss the basics of the metal bending process, including the techniques, tools, and materials involved.

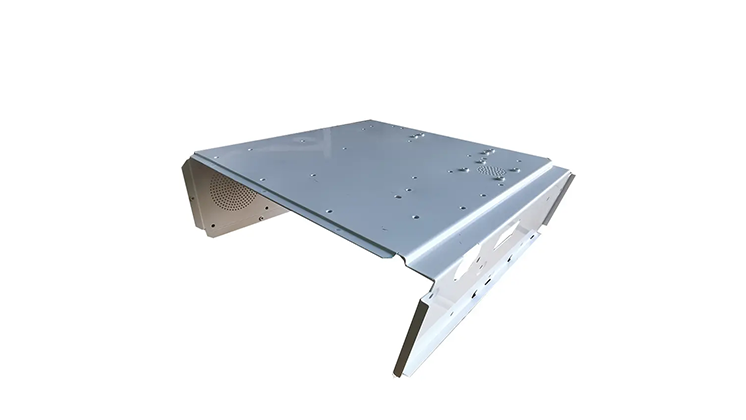

The stainless steel sheet metal bending process is a fundamental manufacturing technique used in various industries such as construction, aerospace, automotive, and electronics. This process involves utilizing techniques like roll bending, press bending, and hot bending, along with tools like bending machines, dies, and heating equipment to shape the metal sheets into the desired form. With the use of strong and durable materials like steel, aluminum, and copper, the metal bending process offers a critical manufacturing solution for achieving precise results in different applications.

Stainless Steel Bending: The Basics is a must-have tool for any team looking to excel in metal fabrication. Our product boasts exceptional durability and precision, making it essential for creating flawless bends in stainless steel. With a strong focus on teamwork and collaboration, this tool enables teams to work efficiently and effectively together, showcasing their collective strength and expertise. The core attributes of our product lie in its high-quality materials and innovative design, while the value attributes include increased productivity and impeccable results. Equip your team with Stainless Steel Bending: The Basics and watch your projects soar to new heights.

In Stainless Steel Bending: The Basics, team strength is a pivotal aspect that sets us apart. Our expert team of highly skilled professionals works together seamlessly to ensure precise and flawless bending of stainless steel. With years of experience and a commitment to excellence, our team collaborates effectively to provide top-notch quality and exceptional customer service. Trust in our team's collective expertise, dedication, and passion for metalworking to deliver superior bending results that exceed expectations. When you choose us, you're not just getting a product, you're getting the support and reliability of a strong, cohesive team behind it.

A Guide to Understanding the Basics

The metal bending process is a fundamental manufacturing technique that involves shaping metal sheets and bars into a desired form. This process is used in a wide range of industries, including construction, aerospace, automotive, and electronics. In this article, we will discuss the basics of the metal bending process, including the techniques, tools, and materials involved.

There are several techniques used in metal bending, including:

Roll bending: This technique involves passing a metal sheet or bars through a series of rollers, which apply pressure and gradually bend the metal into the desired shape.

Press bending: In this technique, a metal sheet or bar is placed between two dies and a press applies force to bend the metal to the desired angle.

Hot bending: This technique involves heating the metal to a high temperature and then bending it while it is still hot. This technique is used for metals that are difficult to bend at room temperature.

Tools

The tools used in metal bending include:

Bending machines: These machines are used to apply force and pressure to the metal during the bending process. They come in various sizes and configurations, depending on the size and thickness of the metal being bent.

Dies: These are specialized tools that are used to shape the metal into a specific form. They come in various shapes and sizes, depending on the desired outcome.

Heating equipment: Hot bending requires specialized heating equipment, such as a furnace or torch, to heat the metal to the required temperature.

Materials

The most commonly used materials in metal bending include:

Steel: This is the most commonly used metal in the metal bending process due to its strength and durability.

Aluminum: This metal is lightweight and has good corrosion resistance, making it a popular choice in the aerospace and automotive industries.

Copper: This metal is highly conductive and is often used in electronics and electrical applications.

Conclusion

The metal bending process is a critical manufacturing technique used in various industries worldwide. Understanding the basics of the metal bending process, including the techniques, tools, and materials involved, can help you make informed decisions when choosing a metal bending service provider or when considering the purchase of a bending machine. Whether you need to bend metal sheets or bars for construction, automotive, aerospace, or electronics applications, the metal bending process can help you achieve your desired results.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.