Recently, I introduced a lot of knowledge about sheet metal bending processing. Today, I will continue to talk to you about what problems need to be paid attention to in the sheet metal bending processing and forming process. The following five aspects are summarized.

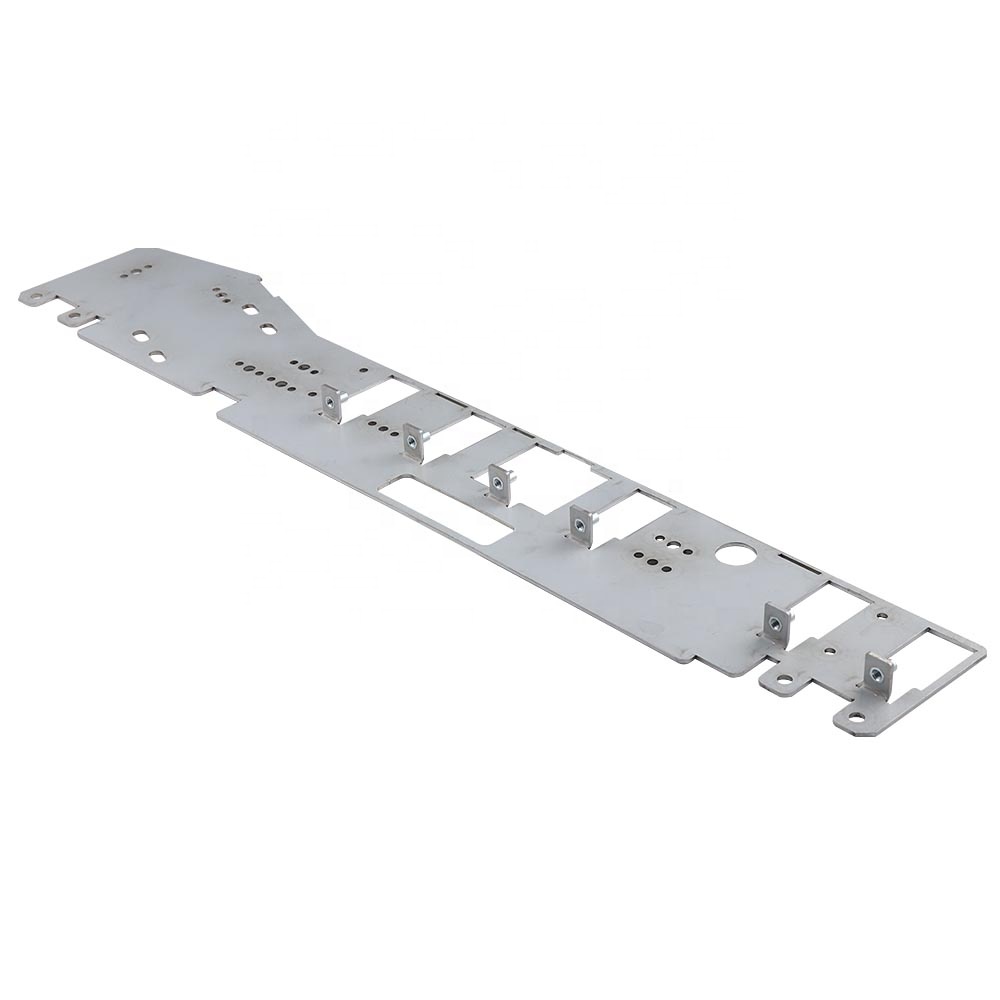

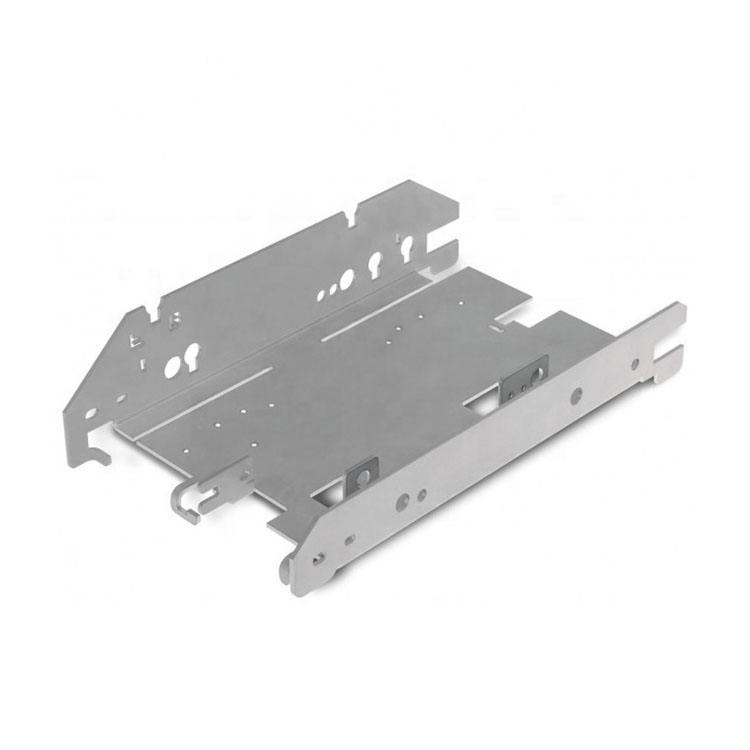

The sheet metal folding services offered by this product include key details such as creating semicircles on both sides of bending lines to prevent protrusion, making R angles before bending to avoid side length issues, and adding narrow or open side holes for smooth edges. Additionally, discounts are made to ensure accuracy, and proper deformation techniques are implemented post-bending for added strength and durability. With a focus on high precision and durability, this product ensures quality through professional control measures and offers online services for customer convenience.

Product Description:

Our team's strength lies in our combined expertise and experience in sheet metal bending. With a diverse group of skilled individuals, we are able to approach each project with innovative solutions and precision. Our team's collaborative nature ensures that we are able to seamlessly work together to achieve the best results for our customers. We value communication and trust among team members, which enables us to meet tight deadlines and exceed expectations. By choosing our team, you can trust that your sheet metal bending needs will be met with professionalism and excellence every step of the way.

Team strength is crucial when it comes to sheet metal bending. Our skilled team of professionals has years of experience and expertise in the field, allowing us to deliver high-quality results every time. With a strong emphasis on collaboration and communication, our team can effectively streamline the bending process, ensuring precision and efficiency. By leveraging each team member's unique strengths and capabilities, we are able to overcome challenges and adapt to customer needs quickly. Trust in our team's proficiency and dedication to provide you with top-notch sheet metal bending services that exceed your expectations.

What are the bending forming process details of sheet metal bending processing?

Recently, I introduced a lot of knowledge about sheet metal bending processing. Today, I will continue to talk to you about what problems need to be paid attention to in the sheet metal bending processing and forming process. The following five aspects are summarized.

Do the semicircle. Make a semicircle on both sides of the bending line first, which can prevent the sheet metal from protruding due to extrusion on both sides of the bending Angle after bending. Convex size and sheet metal thickness, the thicker the material, the more convex, therefore, the diameter of the semicircle are better than 1.5 times the thickness of the material.

Do R Angle. If you do not make R Angle, after many times of stamping, the original right Angle will gradually disappear to form R Angle, but at this time, one side or both sides of R Angle will have a little side length. Therefore, make R Angle before bending, and the Angle inside should be greater than or equal to half of the material thickness. If there is no clear requirement a right Angle, should be processed into an R Angle; In the process of drawing, R Angle should be marked to avoid damage to the mold when the line is stopped.

Make a narrow or open side hole. In order to avoid rough edges, it is necessary to make a narrow hole or edge hole at the turning point between the plane and the bending surface, and the width of the narrow hole should be greater than or equal to 1.5 times the thickness of the meat.

A discount. The discount edge is divided into unilateral and bilateral, compared with unilateral discount, the bilateral discount is more accurate, and the height of the discount edge is greater than 3mm; The parts on the side wall are required to be more than 10mm from the bottom surface; There are side wall opening can not be too close to the bottom surface, to keep above 3mm, otherwise the hole will be deformed by pressure.

It should be deformed after bending. There are two cases of deformation. First, in view of the deformation formed by the force after bending, without affecting other parts, can be added in the bending Angle of 45 degrees of reinforcing additives, increase the strength; Two, because the plate shape is long and narrow type is not easy to keep straight, bending deformation, which can be folded an L or folded two inverted "U" type edge, but sometimes will be interrupted by some factors, can not connect from head to tail, then you can play the right amount of convex ribs to increase its strength.

Bending processing molding

The above is to give you a summary of the bending molding process need to pay attention to the aspects, I hope to help you. Bergek processing plant with experience to tell you the small details of sheet metal bending process, so that you can avoid mistakes in the process of operation, but also in strict accordance with customer requirements drawings for processing.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.