For any structural part, it has a certain processing process. First the sheet metal fabrication plant parts design and draw drawings, the structure of the expression; Then the complex structure of the parts into a shape and easy to process the hole of the workpiece. Next to the processing link, according to the differences in sheet metal parts structure, the sheet metal process is different, summarize the following points.

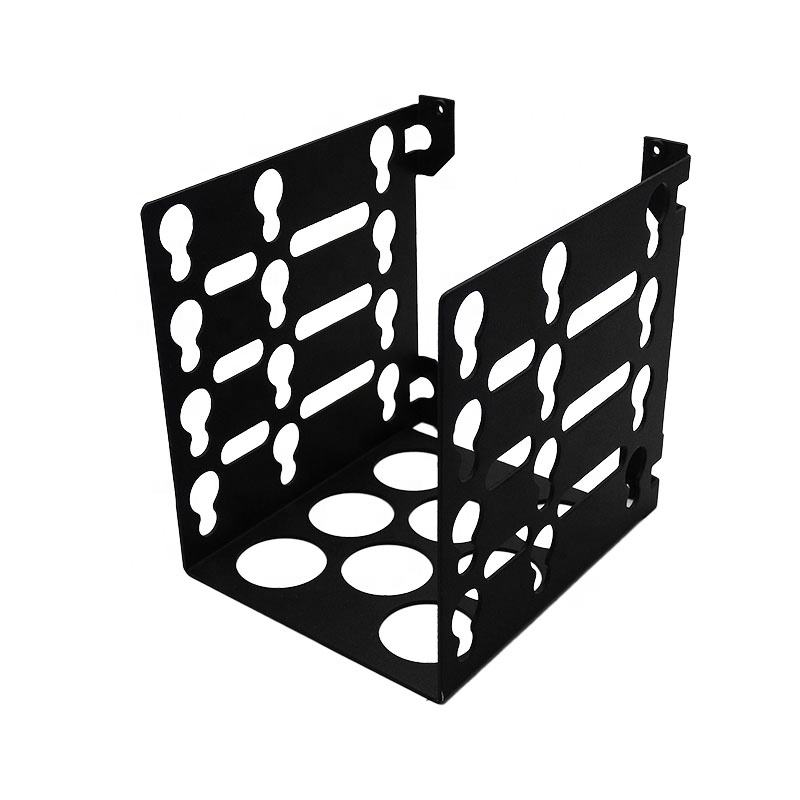

Crafted with advanced precision sheet metal fabrication and expert metal bending techniques, this product ensures exceptional durability and accurate dimensions for reliable performance. Leveraging years of industry expertise, it combines robust construction with sleek design, offering enhanced strength and seamless integration in various applications. Key features include high-quality material selection, precise bending tolerances, and corrosion resistance, making it ideal for demanding industrial and commercial use.

We serve a diverse range of industries with precision sheet metal fabrication and expert metal bending services designed to meet your exact specifications. Our core attributes include advanced technology, skilled craftsmanship, and strict quality control, ensuring durable, accurate, and customized metal components. We add value by offering fast turnaround times, competitive pricing, and seamless integration with your manufacturing processes. Whether you require prototypes or large-scale production runs, we are committed to delivering reliable solutions that enhance your product performance and operational efficiency. With a customer-focused approach, we support your business growth through consistent, high-quality metal fabrication services.

We serve a diverse range of industries requiring precision sheet metal fabrication and expert metal bending services. Our core strength lies in delivering high-quality, custom-engineered metal components with exceptional accuracy and consistency. Whether you need prototypes, small batch runs, or large-scale production, we provide solutions tailored to your specifications. Our value-driven approach emphasizes reliability, timely delivery, and cost-effective processes, ensuring your projects stay on schedule and within budget. With advanced technology and skilled craftsmanship, we empower manufacturers, fabricators, and designers to bring their complex metal designs to life efficiently and flawlessly. Your precision metal needs are our priority.

For any structural part, it has a certain processing process. First the sheet metal fabrication plant parts design and draw drawings, the structure of the expression; Then the complex structure of the parts into a shape and easy to process the hole of the workpiece. Next to the processing link, according to the differences in sheet metal parts structure, the sheet metal process is different, summarize the following points.

1. Blanking. There are many ways of blanking, mainly the following four ways: cutting bed blanking. It is the use of a cutting machine to cut out the length and width of the outline of the diagram. Only the maximum size of the workpiece can be cut out; Punch blanking. Is the use of punch to its shape and hole processing, mass production punch blanking has more advantages;

There are two kinds of CNC blanking, the workpiece made of high precision: CNC number punching blanking and laser blanking. The former is more suitable for the sheet under a 3.0mm plate, the latter is suitable for a more complex structure of the workpiece and a thicker sheet workpiece

2. Flanging. Flanging is also called turning hole, hole extraction is to draw a specified size hole on the pre-punching, the sheet metal process can make the workpiece tapping teeth more strength, suitable for the thickness of the plate below 1.5mm workpiece

3. Pressure riveting. Pressure riveting commonly uses studs, nuts, screws, etc., pressure riveting can be riveted to the sheet metal parts through the punch or pressure riveting machine.

4. Bending. Bending is to strengthen the strength of the workpiece. Its processing needs a folding bed and related bending die to complete.

5. Welding. Welding is welding 2 or more 2 parts together to achieve the purpose of processing, Or the edge seam of a single part should be welded to increase the strength of the hem. Its processing types are two-protection welding, argon arc welding, electric welding, robot welding, and collision welding, etc.

6. Surface treatment. Surface treatment has phosphating film, electroplating colorful zinc, chromate, paint, oxidation, etc. Phosphating film is suitable for cold-rolled plates and electrolytic plates; Electroplating colorful zinc is generally used for the surface treatment of cold-rolled plates and machined parts; Chromate, oxidation is generally used for the surface treatment of aluminum and aluminum profiles; The specific surface treatment is based on customer material requirements.

7. Assembly: It is to put multiple parts or components together according to the requirements of the drawing to make it into a complete part. The assembled parts may be finished or semi-finished

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.