Customers who have used laser cutting technology know that laser cutting processing technology is a kind of use of laser beam on the surface of the accessories continuous movement to achieve, and this kind of work in the laser beam has good directivity but also has a good correlation, its cutting ability density is good, is also very large.

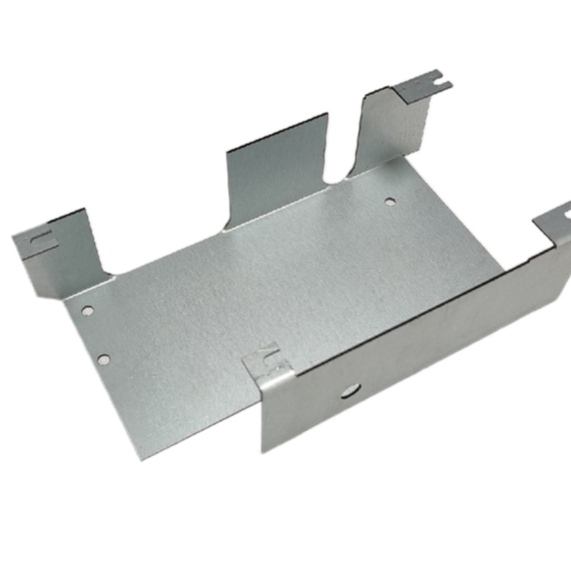

Sheet metal laser parts are crafted with high-precision laser cutting technology that ensures fast processing speeds and clean, deformation-free edges due to the focused laser beam's intense energy concentration. This method offers strong adaptability by minimizing heat-affected zones, enabling the processing of various materials with excellent sensitivity and controlled cutting tracks. The resulting sheet metal laser parts feature finely detailed cuts, smooth edges, and enhanced structural integrity, delivering both functional performance and aesthetic quality in demanding applications.

Our company specializes in delivering high-precision sheet metal laser cutting parts, renowned for fast turnaround times and exceptionally clean edges. Combining advanced laser technology with expert craftsmanship, we ensure accurate, reliable components tailored to diverse industrial needs. Committed to quality and innovation, we prioritize customer satisfaction by offering customized solutions, strict quality control, and responsive service. Our state-of-the-art facilities and experienced team enable efficient production without compromising precision. Partnering with us means accessing cutting-edge manufacturing capabilities that enhance your product performance, reduce waste, and accelerate project timelines, making us a trusted leader in the sheet metal laser cutting industry.

Our company specializes in high-precision sheet metal laser cutting, delivering parts with fast, clean edges that meet the most demanding industry standards. With advanced technology and expert craftsmanship, we ensure exceptional accuracy and consistent quality in every order. Committed to innovation and customer satisfaction, we blend cutting-edge laser systems with efficient processes to provide rapid turnaround times and cost-effective solutions. Our dedication to reliability and precision supports diverse sectors, enabling clients to enhance product performance and assembly efficiency. Partner with us for superior sheet metal components that drive your projects forward with unmatched precision and service excellence.

Customers who have used laser cutting technology know that laser cutting processing technology is a kind of use of laser beam on the surface of the accessories continuous movement to achieve, and this kind of work in the laser beam has good directivity but also has a good correlation, its cutting ability density is good, is also very large.

First, laser cutting characteristics:

1, in the cutting quality, is high quality, fine.

This kind of laser equipment used to cut the laser beam can be focused on a small spot of light so that the laser cutting machine to achieve a high use of power, thus cutting speed is fast, with very high precision, but also to ensure that the workpiece will not appear deformation.

2, strong adaptability, high sensitivity.

This cutting method adopts the hot cutting technology, when cutting the affected area is small, will not have a large impact. Another advantage is that it can process some non-metal, of course, this is also what other laser-cutting equipment can not do.

3, large energy, can control the change of its density, and can also be a local operation.

This kind of laser has good control performance, can freely control the laser cutting machine running track, and any hard material can be made corresponding cutting. With these gadgets, we can also cut locally.

Two, the laser cutting process has the following kinds:

1. The fusion cutting method is to irradiate the laser incident speed of light into the plate. When the laser power reaches a certain critical value, the local area will be melted, so as to achieve the cutting effect.

2, vaporization cutting with high power density laser to heat processing materials, avoid the melting caused by heat conduction and the formation of hanging slag burr, part of the material evaporates after evaporation, the edge is beautiful.

3. Oxidation cutting refers to the hot processing caused by the oxygen blowing and the laser lighting in the nozzle, and the intense chemical reaction of oxygen occurs; For brittle materials vulnerable to heat damage, high-speed controlled cutting can be achieved by heating laser beam, which leads to the large thermal gradient in the area, serious mechanical deformation, and material cracking, also known as controlled fracture cutting.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.