Product advantages

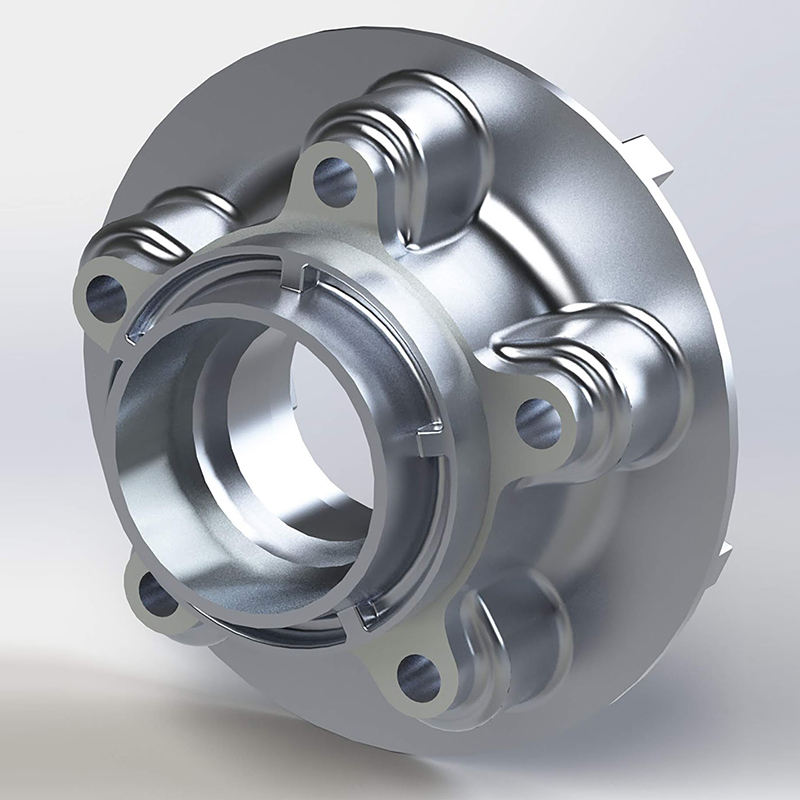

Our CNC Titanium Machining product offers unparalleled strength, lightweight design, and exceptional corrosion resistance. Crafted with precision using advanced CNC technology, our titanium products are built to last and withstand the toughest conditions. Elevate your projects with the high-performance advantages of our CNC Titanium Machining.

We serve

At our company, we specialize in providing top-quality CNC titanium machining services. Our team is dedicated to delivering products that are not only high strength, lightweight, and corrosion-resistant, but also tailored to meet the unique needs of our customers. We serve a wide range of industries, from aerospace to medical, with precision and efficiency. Our commitment to excellence and customer satisfaction sets us apart in the e-commerce market, ensuring that each product we produce is of the highest quality. Trust us to serve your machining needs with expertise and professionalism.

Enterprise core strength

At our CNC Titanium Machining shop, we are dedicated to serving our customers with high-quality products that boast unbeatable strength, lightweight design, and impressive corrosion resistance. Our team of experts is committed to delivering precision-engineered components that meet and exceed industry standards. With our state-of-the-art technology and years of experience, we can guarantee exceptional results that cater to a diverse range of needs. Whether you are in the aerospace, automotive, or medical industry, we are here to serve you with top-notch machining services that will elevate your projects to new heights. Experience the difference with our dedicated team today.

In the global market, titanium alloy materials are mainly used in the aviation industry, national defense, military, and other industries. Among them, the application demand in the aviation industry is the largest, accounting for about 50%, mainly for the manufacture of aircraft and engines.

The strength of titanium alloy products is very high in metal structural materials, its strength is comparable with steel, but its weight is only 57% of steel. In addition, titanium alloy has the characteristics of small specific gravity, high thermal strength, thermal stability, and corrosion resistance, but titanium alloy material cutting processing is difficult, and processing efficiency is low. So how to overcome the titanium alloy processing difficult, low efficiency has been a problem to be solved.

Titanium alloys refer to a variety of alloy metals made of titanium and other metals. Titanium is an important structural metal developed in the 1950s. Titanium alloy has high strength, good corrosion resistance, and high heat resistance. In the 1950s and 1960s, it mainly developed high-temperature titanium alloys for aero-engines and structural titanium alloys for airframes.

Titanium alloys refer to a variety of alloy metals made of titanium and other metals. Titanium is an important structural metal developed in the 1950s. Titanium alloy has high strength, good corrosion resistance, and high heat resistance. In the 1950s and 1960s, it mainly developed high-temperature titanium alloys for aero-engines and structural titanium alloys for airframes.

Characteristics of titanium alloys

◪ High strength, lightweight (strength to weight ratio is very high in metal structural materials)

◪ High-temperature resistance (stable performance at 400-500℃)

◪ titanium oxide, nitride, and carbide corrosion resistance is excellent

◪ Good affinity with objects

Turning titanium alloy products, easy obtaining better surface roughness, and

work hardening is not serious, but the cutting temperature is high, tool wears

fast. Lower cutting speed, moderate feed, deeper cutting depth, full cooling, the car

is round when the tip can not be higher than the workpiece center, otherwise

easy to stick, fine turning and turning thin-walled parts, the main Angle of the

tool to be large, generally 75-90 degrees.

Titanium alloy products milling is more difficult than turning, because milling is intermittent cutting, and chips easy to bond with the blade, when the chip teeth are cut into the workpiece again, the chip is knocked off and take away a small piece of tool material, forming a breaking edge, greatly reduce the durability of the tool.

Titanium alloy products tapping, because the chip is small, easy to bond with the blade and the workpiece, resulting in machining surface roughness value, and large torque. Tapping tap [V] improper selection and improper operation is very easy to cause work hardening, machining efficiency is very low and there is a tap broken phenomenon.

The focus of titanium alloy processing is heat, a large number of high-pressure cutting fluids for timely and accurate injection on the cutting edge can quickly remove the heat. The cutting process of titanium alloy material must be controlled from the aspects of tool material, cutting fluid, and processing parameters, so as to improve the comprehensive efficiency of titanium alloy material processing.