Now many mechanical parts, the process need to punch hole position chamfering processing, also need to it on the polishing wheel rims of coarse and fine buffing, these three procedures are usually separate processing, low efficiency, the need to design a kind of material can be chamfering processing, coarse and fine buffing integration processing equipment.

Depending on the material used, a variety of processes are often used to create a variety of beautiful appearances on the surface of the product. The product surface treatment method, according to its surface characteristics or/and beauty and other application categories, can be divided into painting, coloring, anodic oxidation, PVD, coating, drawing, polishing, sandblasting, laser marking, CNC processing, heat treatment, and other processes.

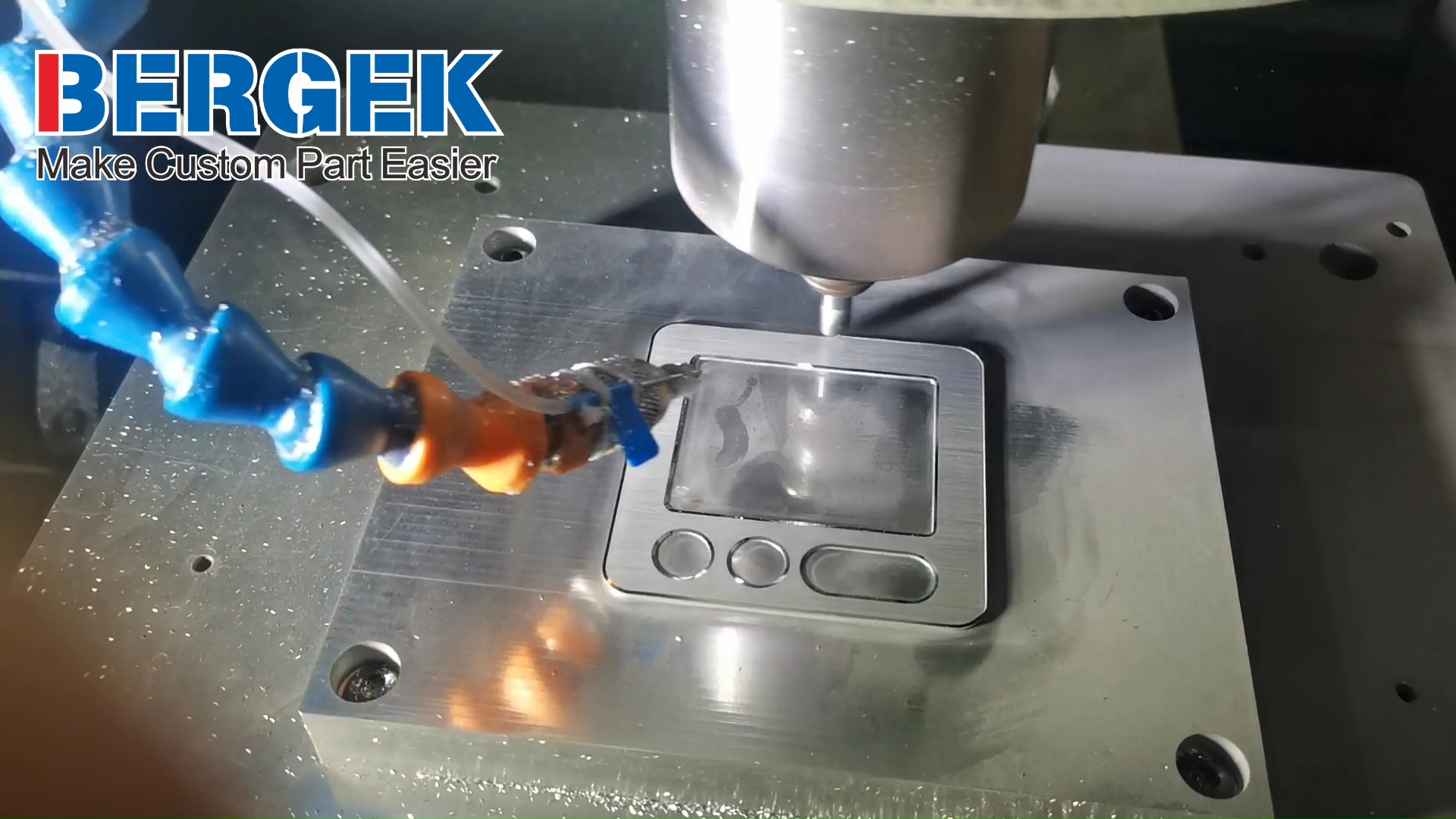

The polishing process usually refers to the step of polishing the workpiece surface after casting the grinding agent on the surface of the workpiece. In more detail, flat (metal or non-metallic) refers to the workpiece surface and the flat mill (flat, polishing cloth, etc.) between the grinding material (diamond, silica, etc.) or after grinding fluid to do relative motion artifacts and plane mill, so because of the action of grinding material, make the workpiece surface roughness to achieve consistently, it is concluded that excellent polished surface, like a mirror This process is called flat polishing.

Due to the general plane polishing of the workpiece and the surface of the

grinding plate face to face with each other to work together, so the workpiece

can only be placed on the surface of the grinding plate and from the vertical

direction of the vertical load for processing. However, it is generally

difficult to carry out high-gloss polishing at the same time for the workpiece

with a three-dimensional shape and composed of composite planes. Therefore, the

plane polishing process in the existing technology is difficult to achieve

multi-surface polishing effect, but also through the multifarious process of

repeatedly disassembling and fixing fixtures. In addition, it is difficult to

reflect the correct polishing surface through the multifarious process of

repeatedly disassembling and installing fixed fixtures. It makes it difficult to

display a beautiful appearance when polishing with a three-dimensional shape

composite plane.

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.