Unlock efficiency & precision with the top 8 benefits of Titanium CNC Machining. Explore its game-changing potential now!

Have you ever wondered why titanium CNC machining is the go-to for top-tier professionals? With its excellent strength-to-weight ratio and resistance to corrosion, titanium is one of the most useful and popular metals for industrial engineers. This post discusses the basics of titanium CNC machining, including the most suitable applications, machining advantages

You're about to dive into a realm where every detail matters. We're peeling back the layers to reveal:

● The essence of Titanium CNC Milling

● The Top 10 Advantages of Using Titanium CNC Machining

● Navigating through Different Titanium Grades for Optimal CNC Machining

When you hear "Titanium CNC Machining," think precision, strength, and innovation. This isn't just a manufacturing process; it's a game-changer in the world of production. But what exactly is it? CNC (Computer Numerical Control) machining is a method used to manage machine tools through the use of computers. Titanium, known for its remarkable strength-to-weight ratio.

Why Titanium?

· Durability Meets Precision: Titanium's robustness is legendary. It withstands extreme conditions without batting an eyelash. Pair that with CNC's precision, and you've got a match made in engineering heaven.

· Lightweight Yet Strong: It's a paradox in the best way possible. Titanium offers the strength of heavier metals without the added weight. This means more efficiency and less strain on machinery.

· Corrosion Resistance: Where other metals falter, titanium stands tall. Its resistance to corrosion makes it ideal for long-lasting applications.

The CNC Edge

· Unmatched Accuracy: Titanium CNC machining provides unparalleled precision. Every cut and every angle is exact, reducing errors and enhancing quality.

· Speed and Efficiency: Time is money, and CNC machining saves plenty of it. Its rapid production capabilities mean you get more done in less time.

· Flexibility in Design: Complex designs? No problem. Titanium CNC machining handles intricate patterns and shapes with ease, opening doors to innovative designs.

This combination of titanium's inherent strengths with CNC's precision and efficiency creates a powerhouse in manufacturing. Whether it's aerospace, medical, or car industries, the impact is profound and far-reaching.

The Top 8 Advantages Of Using Titanium CNC Machining

1. Strength-To-Weight Ratio

Titanium's strength-to-weight ratio is one of the highest among engineering metals, typically about 288 kN·m/kg, compared to 156 kN·m/kg for pure aluminum. This ratio is crucial in aerospace, where reducing weight without compromising strength can significantly enhance aircraft performance. For instance, using titanium cnc machining part in aircraft structures can reduce weight by up to 40% compared to traditional steel.

In automotive engineering, this ratio translates to lighter vehicles with improved fuel efficiency. For example, replacing steel components in a car with titanium can lead to a weight reduction of about 10%, directly impacting fuel economy and emissions.

2. Corrosion Resistance

Titanium forms a passive oxide layer, protecting it from corrosion. This resistance is particularly beneficial in environments with chloride exposure, where it can outperform stainless steels. In marine applications, titanium exhibits a corrosion rate of less than 0.01 mm/year in seawater, significantly higher than many other metals.

3. High-Temperature Performance

Titanium cnc parts maintains its strength up to temperatures of 600°C, far higher than aluminum (which weakens around 200°C). This property is vital in jet engines, where temperatures can exceed 400°C. Titanium alloys used in these applications, like Ti-6Al-4V, retain more than 90% of their room-temperature tensile strength at 400°C.

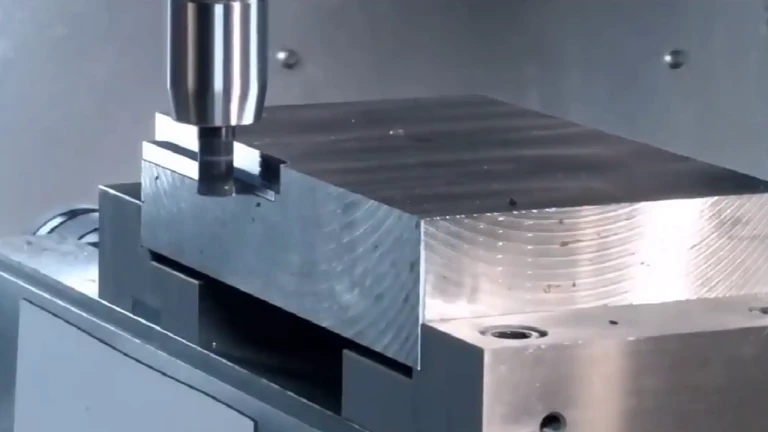

Bergek CNC titanium parts case

4. Biocompatibility

Titanium is non-toxic and fully biocompatible, making it ideal for medical implants. Its Young's modulus (around 110 GPa) is closer to that of human bone (10-30 GPa) compared to stainless steel (200 GPa), reducing bone resorption and implant loosening risks. The material's ability to osseointegrate or bond with bone tissue is crucial for long-term implant stability.

5. Lightweight

Titanium's density is about 60% that of steel, making it significantly lighter. In the aerospace industry, this translates to substantial fuel savings. In consumer electronics, the use of titanium allows for lighter and more durable devices. A titanium smartphone case, for instance, can be up to 40% lighter than a comparable steel case.

6. Non-Magnetic Properties

Titanium is non-ferromagnetic, which is crucial in applications where magnetic interference must be avoided. In medical imaging equipment like MRI machines, CNC titanium machining ensures no magnetic interference, which is critical for accurate diagnostics. In electronic devices and aerospace components, titanium's non-magnetic nature prevents disruption of sensitive electronic systems and navigation instruments, ensuring reliable operation in critical applications.

Bergek titanium CNC machining parts

7. Cost-Effectiveness

In industrial applications, the extended lifespan of titanium CNC machining parts can lead to a total cost of ownership that is up to 20% lower than that of less durable materials. In aerospace, the use of titanium, despite its higher upfront cost. For instance, the use of titanium in aircraft engines has been shown to reduce overall lifecycle costs by up to 30% compared to traditional materials.

8. Multifunction

Titanium cnc machining's versatility is showcased in its wide range of alloys. For example, Ti-6Al-4V, the most commonly used titanium alloy, offers a good balance of strength, weight, and corrosion resistance. In the electronics industry, titanium's non-reactive nature makes it ideal for semiconductor manufacturing equipment. Its ability to withstand corrosive chemicals used in semiconductor processing.

Introduce BERGEK Titanium CNC Machining Service

Bergek CNC titanium machining service supplier can perform various operations such as milling, turning, drilling, and grinding on titanium, providing a versatile solution for a wide range of part geometries. Bergek is good at making prototypes, small-batch, or mass production customized titanium CNC machining parts.

1. We Offer repaid CNC prototypes,small-batch machining, and high-volume production, with all orders serviced by one-to-one service.

2. Only need to submit 2D and 3D CAD drawings, we can custom titanium parts tailored to specific designs and requirements

3. Our machinists and engineers with expertise in working with titanium, ensuring the optimal machining parameters are applied for quality results.

Different Titanium Grades For CNC Machining

Titanium's versatility is further enhanced by its various grades, each tailored for specific applications. Understanding these grades is key to maximizing the benefits of titanium CNC machining. Let's explore the advantages of titanium plates in precision engineering.

Grade 5 Titanium (Ti-6Al-4V)

Often referred to as the "workhorse" of the titanium industry, Grade 5 titanium, or Ti-6Al-4V, is an alloy made with 6% aluminum and 4% vanadium. It's the most widely used titanium alloy, accounting for 50% of total titanium usage worldwide.

· High Strength: With a tensile strength of 1000 MPa and a yield strength of 880 MPa, it's significantly stronger than pure titanium.

· Heat Resistance: Titanium cnc machining parts Maintains its strength at temperatures up to 400°C, making it ideal for high-temperature applications.

· Versatility: Used in aerospace, medical implants, and automotive industries due to its balanced properties.

Grade 2 Titanium

Grade 2 titanium is commercially pure titanium. It's the most used grade of pure titanium and offers a great balance of strength, ductility, and corrosion resistance.

· Excellent Corrosion Resistance: Grade 2 Titanium cnc machining parts is Ideal for chemical and marine applications.

· Good Weldability and Formability: Makes it suitable for various manufacturing processes.

· Biocompatibility: Widely used in medical applications, including orthopedic implants.

Grade 23 Titanium (Ti-6Al-4V ELI)

Grade 23, also known as Ti-6Al-4V ELI (Extra Low Interstitial), is similar to Grade 5 but has reduced oxygen, nitrogen, and carbon content. This makes it even more biocompatible.

· High Purity: Preferred for medical implants, especially where a higher fracture resistance is required.

· Low Oxygen Content: Enhances ductility and fracture toughness.

· Used in Sensitive Applications: Ideal for surgical devices and implants.

Grade 7 Titanium

Grade 7 contains palladium, which significantly increases its corrosion resistance, especially in reducing acids.

· Superior Corrosion Resistance: Particularly effective against reducing acids and localized attack in hot halide environments.

· Chemical Processing Applications: Its enhanced properties make it suitable for chemical processing equipment.

· Similar Mechanical Properties to Grade 2: Offers a good balance of strength and formability.

Grade 12 Titanium

Grade 12 titanium is a highly durable alloy containing nickel and molybdenum, which enhances its strength and corrosion resistance.

· Increased Strength and Thermal Stability: Suitable for high-temperature applications.

· Excellent Corrosion Resistance: Particularly in oxidizing and mildly reducing environments.

· Versatile Industrial Applications: Used in chemical processing, power generation, and marine industries.

Each of these grades offers unique advantages, making them suitable for a wide range of applications. The choice of grade depends on factors like required strength, corrosion resistance, formability, and specific industry requirements. By selecting the appropriate grade for your titanium CNC machining project, you can optimize performance, durability, and cost-effectiveness.

Harnessing The Full Potential Of Titanium CNC Machining

In conclusion, the world of manufacturing and design is witnessing a transformative era with Titanium CNC Machining. From its unparalleled strength-to-weight ratio to its exceptional corrosion resistance, titanium stands as a beacon of innovation and efficiency in modern engineering. The detailed exploration of its top advantages reveals a material that is not just about enhancing performance but redefining possibilities.

In embracing Titanium CNC Machining, we're not just elevating our craft; The versatility of titanium, highlighted through its various grades, underscores its adaptability across diverse industries. Whether it's the robustness of Grade 5 for aerospace, the purity of Grade 2 for medical implants, or the enhanced corrosion resistance of Grade 7 for chemical processing, titanium offers tailored solutions for the most demanding applications. Contact us to get best titanium CNC machining serivce!

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.