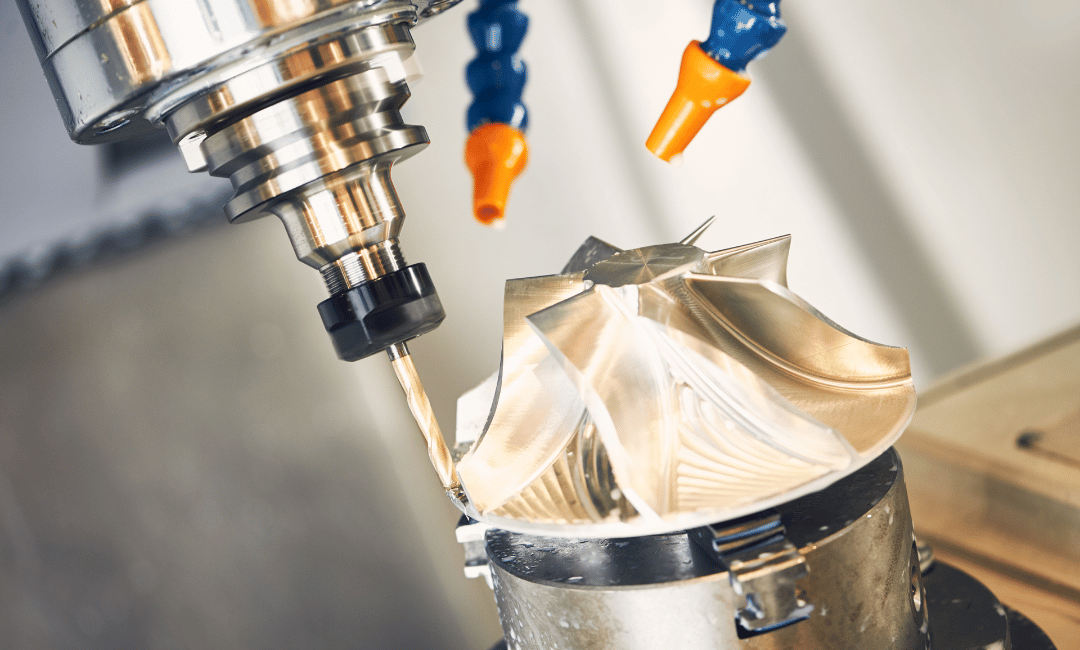

The CNC machining process offers many advantages because it is automated and uses computer-controlled machine tools to fabricate parts from raw materials.

Dive into the world of precision and efficiency where CNC machining stands tall. Have you ever wondered how some projects scream perfection while others barely make the cut? The secret's out: CNC machining. CNC machining serivce is not only efficient, but it can also minimize material wastage thanks to its precision and accuracy.

In this article, we unveil the gems of CNC machining:

●Precision: Achieve exact cuts, every single time.

●Speed and Efficiency: Say goodbye to delays.

●Flexibility for Creativity: Your imagination is the only limit.

●Cost-Effective Production: Quality meets affordability.

●Minimal Waste: A step towards greener production.

So let's get started.

What is CNC Machining?

CNC machining service is a digital manufacturing technology: it produces high-accuracy parts with excellent physical properties directly from a CAD file. Due to the high level of automation, CNC machining service is price-competitive for both one-off custom parts and medium-volume productions. Almost every material can be CNC machined. The most common examples include metals (aluminum and steel alloys, brass etc) and plastics (ABS, Delrin, Nylon etc). Foam, composites and wood can also be machined.

Beneifts Of Choosing CNC Machining

CNC machining service is more accurate and has no defects. In a world where every detail counts, custom CNC machining service takes the spotlight, championing a level of precision that traditional methods can't hold a candle to. It's about making the right cuts, down to fractions of a millimeter. One of the major CNC fabrication benefits is accuracy. Because CNC machines receive precise instructions from a computer — and the movements are similarly carried out under computer control — their results will be identical each time and will match the computer model closely. Complex geometries? Intricate details? All within reach. Whether it's aerospace components that demand astronautical accuracy or bespoke jewelry that captures the imagination, Best CNC machining makes it possible.

Time is of the essence, especially in manufacturing. CNC machining offers more rapid and effective production. Let's break it down. Traditional machining requires manual adjustments, tool changes, and constant supervision. However, another industry-cornering CNC machining service benefit is the inherent speed and efficiency of production. Custom CNC machining service is capable of producing products much more quickly and efficiently than traditional methods.

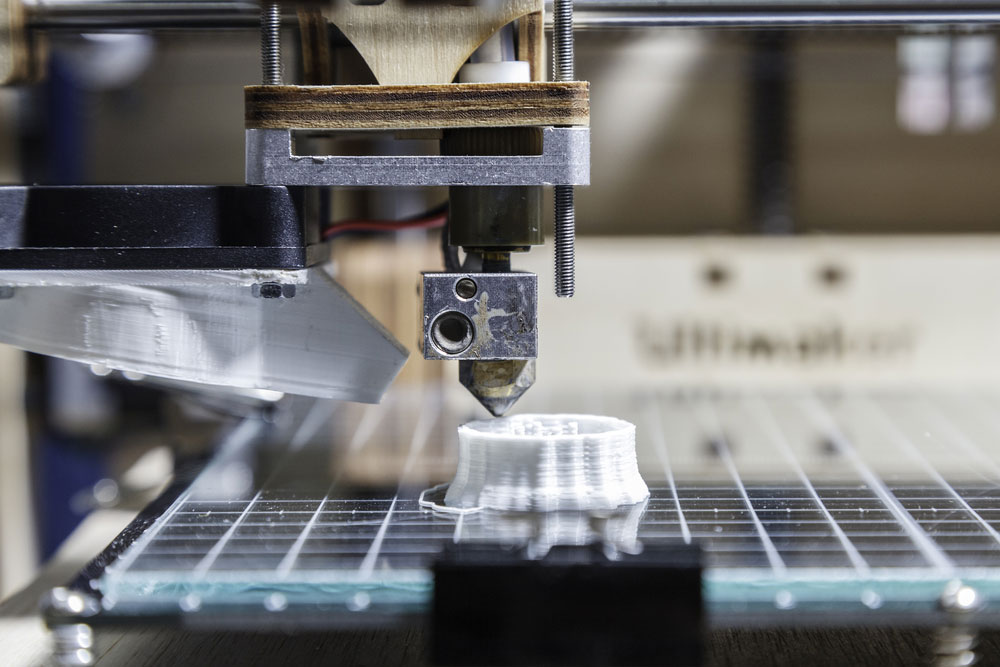

Rapid prototyping becomes a breeze, turning ideas into tangible products at breakneck speeds. Small batch production? No problem. Need to scale up? Custom CNC machining service is ready to meet the demand without breaking a sweat. In an industry where time-to-market can make or break success, CNC machining is not just a tool; it's your competitive edge. CNC machining service leads to significant cost savings and increased productivity.

Bergek CNC Service Types

Can be manufactured in small batches of sheet metal, helping you develop markets before full-scale production, of fully finished precision sheet metal parts such as brackets, plates, frames, arms, busbars, fixtures, etc.

Bergek CNC provides the best CNC machining services in the industry, supporting you to gain a good reputation in the market. Various processes based on DFM audits are combined with CNC machining

Included Prototyping and on-demand High-volume manufacturing service for complex plastic injection molded parts Better yet, your prototyping tool is free once you shift to an on-demand manufacturing tool.

Good surface treatment increase the value to the customer's brand. In order to provide lower costs many parts combine extrusion, low pressure casting and CNC machining. It saves cost and time also fast delivery.

CNC machining service is a game-changer for designers and engineers, enabling the creation of components that would be impossible or prohibitively expensive with traditional methods.

This flexibility stems from CNC machining's ability to work with a vast array of materials, from soft plastics to hard metals and everything in between. Whether you're crafting a delicate piece of jewelry that demands the precision of a surgeon or an engine part that needs to withstand extreme pressures, CNC machining service adapts to your needs. Iteration becomes rapid and cost-effective, pushing the boundaries of innovation. CNC fabrication service ensures that your projects aren't just completed; they're perfected.

CNC machining service stands out not just for its technical prowess but for its cost-effectiveness. It's a common misconception that high precision and speed come with a hefty price tag. CNC machining flips this narrative, demonstrating that quality and affordability can coexist. The secret? Minimizing waste and human error. Traditional machining methods are prone to mistakes, each costing time and materials. Custom CNC machining service's precision virtually eliminates these errors, ensuring that materials are used optimally. Less waste means lower costs, a benefit that ultimately finds its way to the bottom line.

CNC machining generates minimal to no waste. In an era where sustainability is not just valued but essential, custom CNC machining presents a compelling advantage: minimal waste. CNC machining service is not only efficient, but it can also minimize material wastage thanks to its precision and accuracy. As long as the part is designed properly in the computer, the machine itself will almost never make faulty cuts, so there will be fewer damaged parts to discard. The machine can handle precise cuts and angles without generating much waste.

Moreover, the digital nature of CNC machining allows for optimal layout and material usage, further minimizing waste. This efficiency is a testament to how modern technology can be harnessed to achieve more with less, paving the way for manufacturing processes that are as kind to the environment as they are to the bottom line.

We've journeyed through the realms of CNC machining, uncovering the layers that make it not just an option but a necessity for precision, speed, and innovation. You now hold the keys to understanding why CNC machining stands as a titan in the world of manufacturing.

Here's benifits of custom CNC machining service

●Unmatched Precision: Elevate your projects with exacting standards.

●Speed and Efficiency: Fast-track your production without a hitch.

●Flexibility for Creativity: Let your imagination run wild.

●Cost-Effective Production: High quality meets affordability.

●Minimal Waste: Embrace a greener approach to manufacturing.

In the landscape of machining and metal part production, Bergek CNC shines as a leading CNC machining supplier, our fleet of CNC machines and expert team ensures your parts are not just made, but crafted to perfection, delivered on time, every time.

Certified under AS9100, BERGEK CNC champions rapid prototyping and small-batch production with a keen eye on quality and efficiency. Whether it's turning or milling, your designs are in capable hands, ready to be transformed into reality. BERGEK CNC provides a wide range of manufacturing capabilities, including CNC machining and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free quote.

Get In Touch With Us!

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.