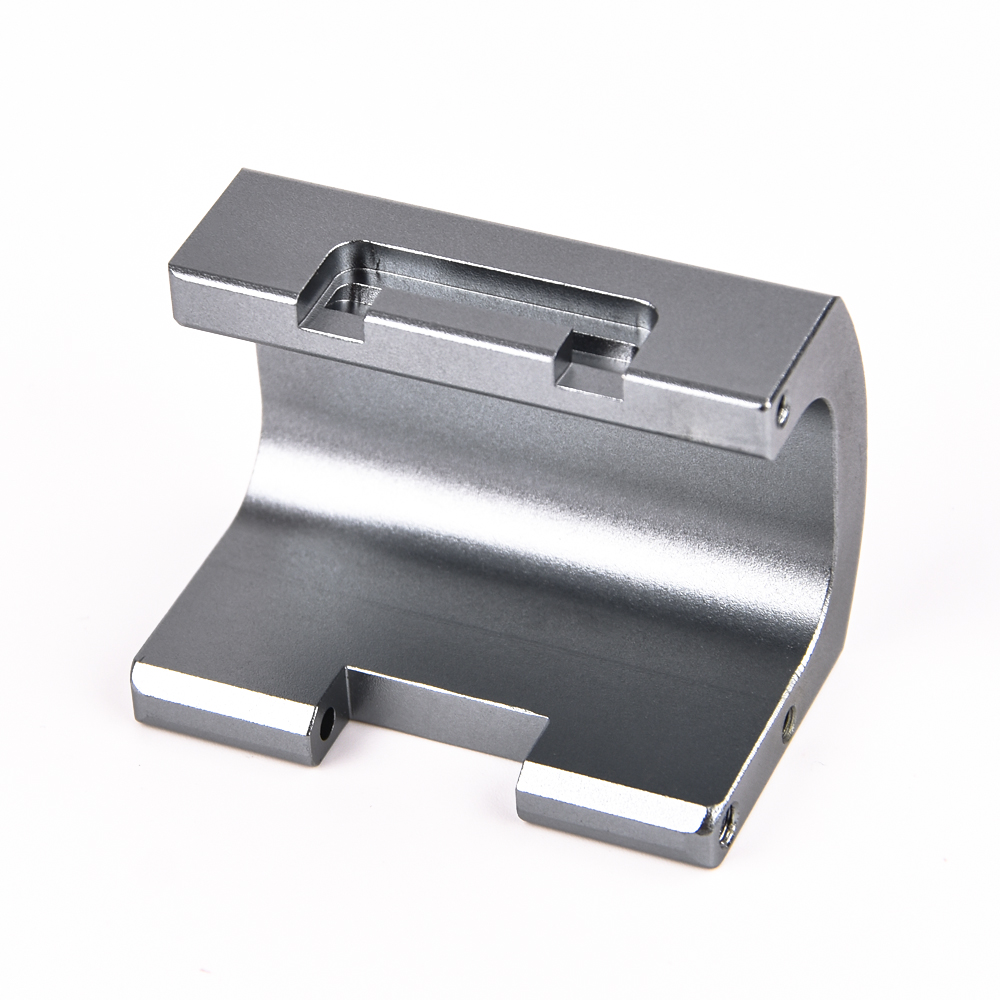

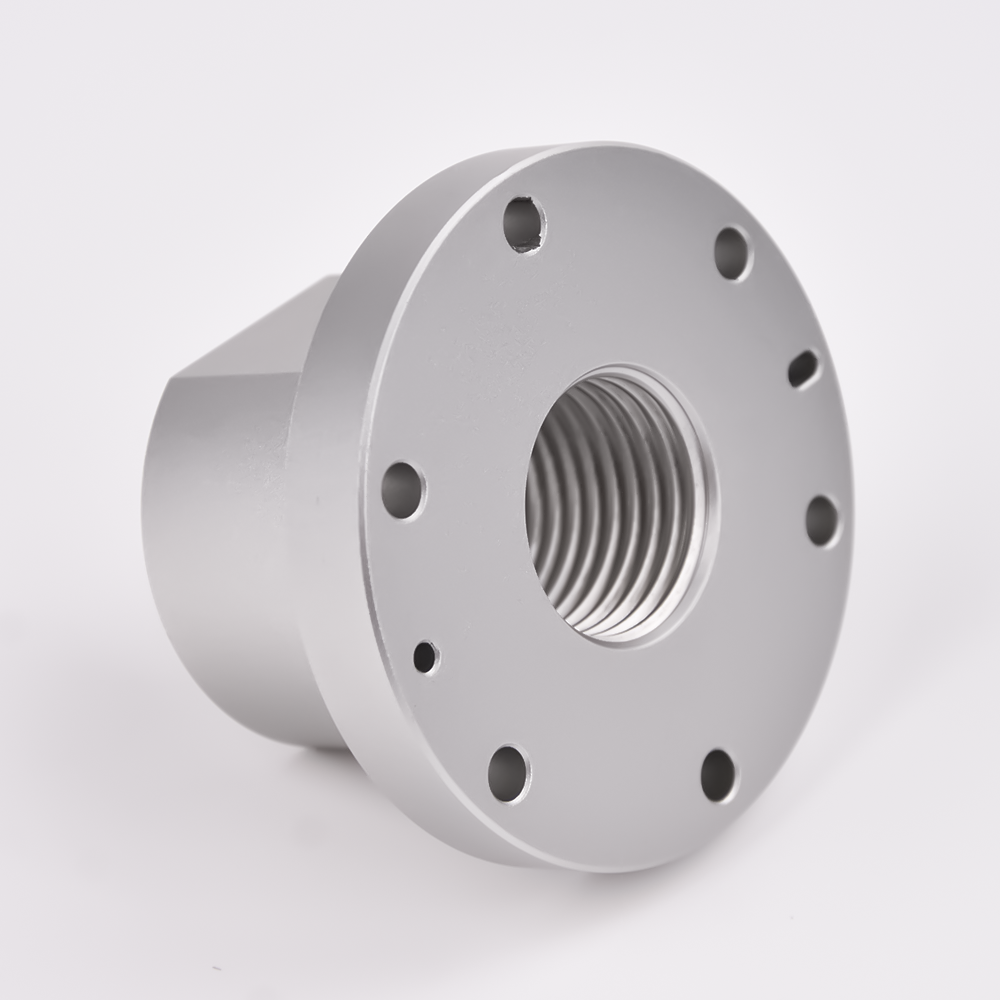

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical cutter head and a number of chip slots are usually called an end milling cutter or end milling cutter. It can move along different axes and is used to process long and narrow slots, grooves, contours, and so on. A milling machine is called a milling machine, a CNC milling machine is usually an exponential control machining center. Milling includes manual milling and CNC milling. Milling is carried out in the machining shop.

Our titanium milling service offers high precision parts processing, allowing for intricate designs and tight tolerances. With advanced technology and skilled technicians, we can ensure a superior level of accuracy and quality in the finished products. The strength and durability of titanium make it an ideal choice for demanding applications in industries such as aerospace, medical, and automotive.

At Titanium Milling, we serve by providing high precision parts processing for a wide range of industries. Our expert team utilizes cutting-edge technology and superior craftsmanship to deliver top-quality products with unparalleled precision. From concept to completion, we are committed to meeting the unique needs of our customers and exceeding their expectations. Our dedication to quality, efficiency, and innovation ensures that every project is completed with the highest level of accuracy and attention to detail. Trust Titanium Milling for all your precision parts processing needs, and experience the difference that our exceptional service can make.

At Titanium Milling, we specialize in high precision parts processing to meet your specific needs. With cutting-edge technology and a team of experienced professionals, we guarantee top-notch quality and accuracy in every project we take on. Our dedication to excellence and attention to detail ensure that your parts are manufactured to the highest standards, delivering superior performance and reliability. We serve industries such as aerospace, automotive, and medical, providing tailored solutions that meet the most demanding requirements. Trust Titanium Milling for all your precision parts processing needs and experience the difference our expertise can make.

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical cutter head and a number of chip slots are usually called an end milling cutter or end milling cutter. It can move along different axes and is used to process long and narrow slots, grooves, contours, and so on. A milling machine is called a milling machine, a CNC milling machine is usually an exponential control machining center. Milling includes manual milling and CNC milling. Milling is carried out in the machining shop.

1, parts processing adaptability, flexibility, can process the contour shape is particularly complex or difficult to control the size of the parts, such as mold parts, shell parts, and so on.

2, can process ordinary machine tools can not process or difficult to process parts, such as mathematical model described by the complex curve parts and three-dimensional space surface parts.

3, can process a clamping positioning, need to carry out multi-process processing parts.

4, high processing accuracy, stable and reliable processing quality.

5, a high degree of production automation, can reduce the operator's labor intensity. Conducive to production management automation.

6, high production efficiency.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.