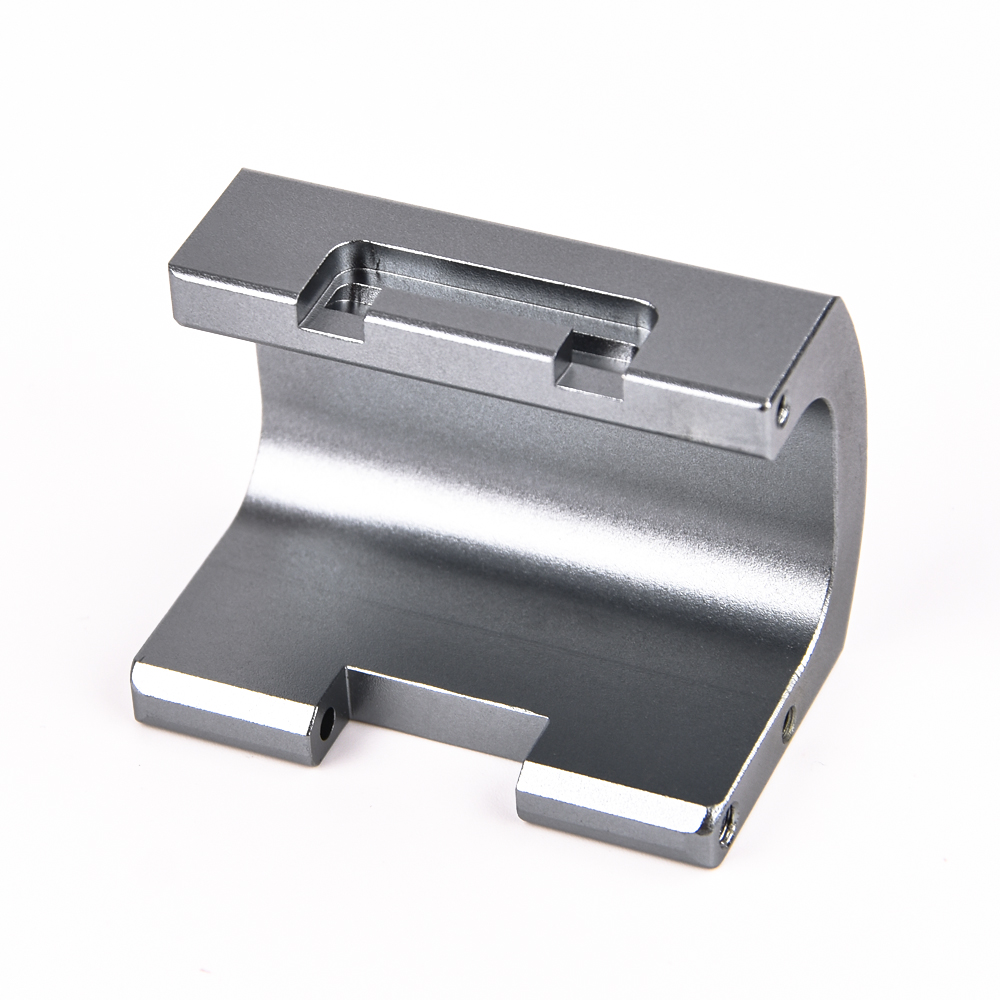

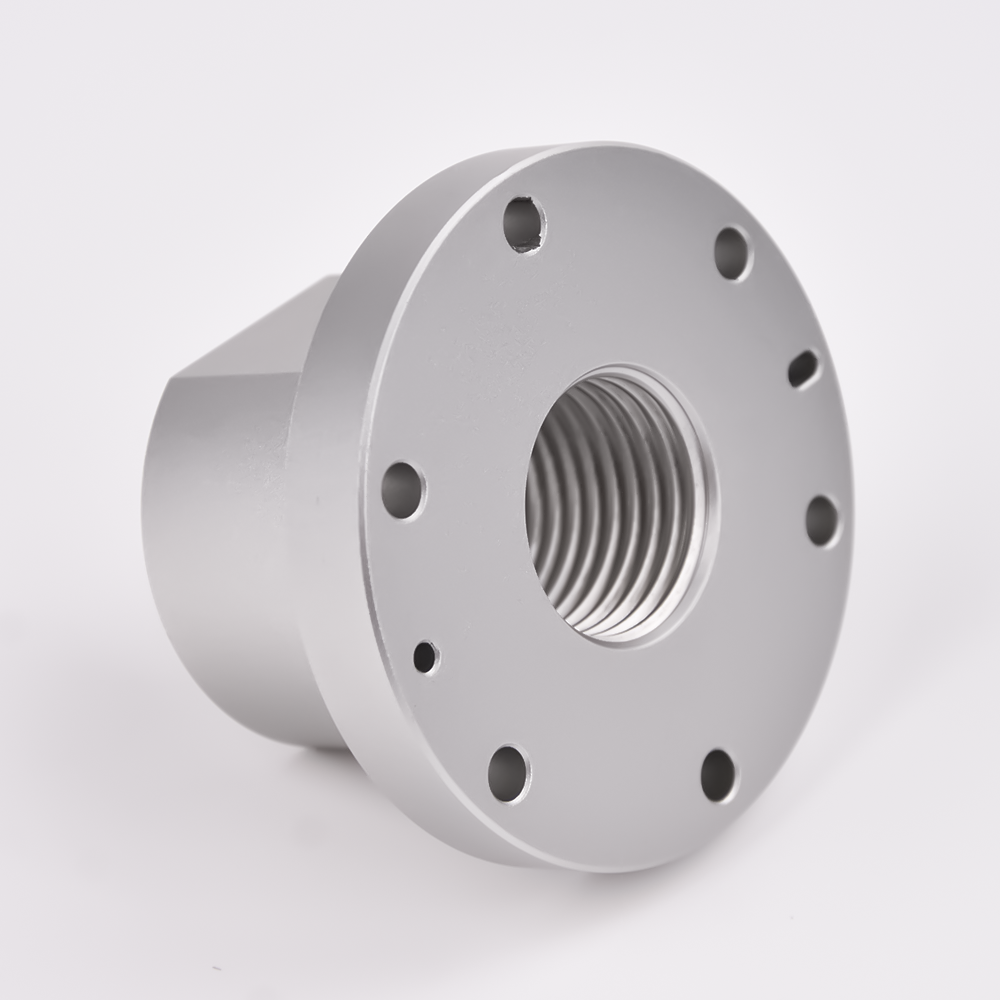

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical cutter head and a number of chip slots are usually called an end milling cutter or end milling cutter. It can move along different axes and is used to process long and narrow slots, grooves, contours, and so on. A milling machine is called a milling machine, a CNC milling machine is usually an exponential control machining center. Milling includes manual milling and CNC milling. Milling is carried out in the machining shop.

Our titanium milling service offers high precision CNC machining for parts processing adaptability, flexibility in handling complex contour shapes, and difficult-to-control sizes. We can process parts that ordinary machine tools struggle with, such as parts with complex curves or three-dimensional space surfaces. With high processing accuracy and reliable quality, our CNC milling service provides high production efficiency and automation to reduce labor intensity, making it the ideal choice for your machining needs.

At Titanium Milling, we specialize in high precision CNC machining to bring our customers top-quality products with unmatched accuracy and quality. Our experienced team of experts is dedicated to serving your needs, whether it's creating custom parts or handling large-scale production runs. We prioritize efficiency and reliability in every project we undertake, ensuring that you receive the best results every time. Trust us to deliver superior craftsmanship and attention to detail, using the latest technology and techniques to meet your specifications. Let us serve you with our commitment to excellence and precision in CNC machining.

At Titanium Milling, we specialize in high precision CNC machining services that deliver top-quality components for a wide range of industries. Our team of skilled engineers and technicians are committed to providing exceptional customer service and ensuring that every project is completed with precision and efficiency. With state-of-the-art technology and a dedication to excellence, we guarantee superior results every time. From complex design challenges to tight deadlines, we serve our clients with professionalism and expertise. Trust Titanium Milling for all your machining needs and experience the difference our commitment to quality makes.

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical cutter head and a number of chip slots are usually called an end milling cutter or end milling cutter. It can move along different axes and is used to process long and narrow slots, grooves, contours, and so on. A milling machine is called a milling machine, a CNC milling machine is usually an exponential control machining center. Milling includes manual milling and CNC milling. Milling is carried out in the machining shop.

1, parts processing adaptability, flexibility, can process the contour shape is particularly complex or difficult to control the size of the parts, such as mold parts, shell parts, and so on.

2, can process ordinary machine tools can not process or difficult to process parts, such as mathematical model described by the complex curve parts and three-dimensional space surface parts.

3, can process a clamping positioning, need to carry out multi-process processing parts.

4, high processing accuracy, stable and reliable processing quality.

5, a high degree of production automation, can reduce the operator's labor intensity. Conducive to production management automation.

6, high production efficiency.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.