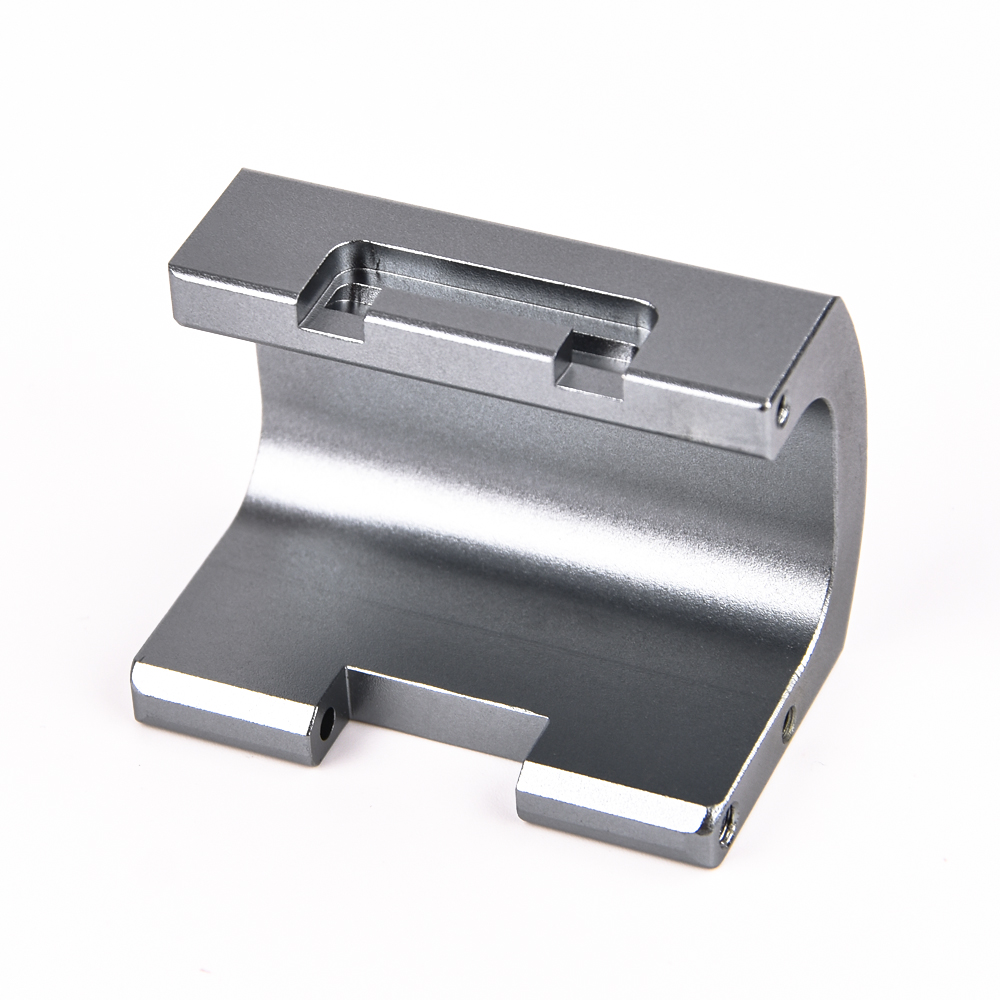

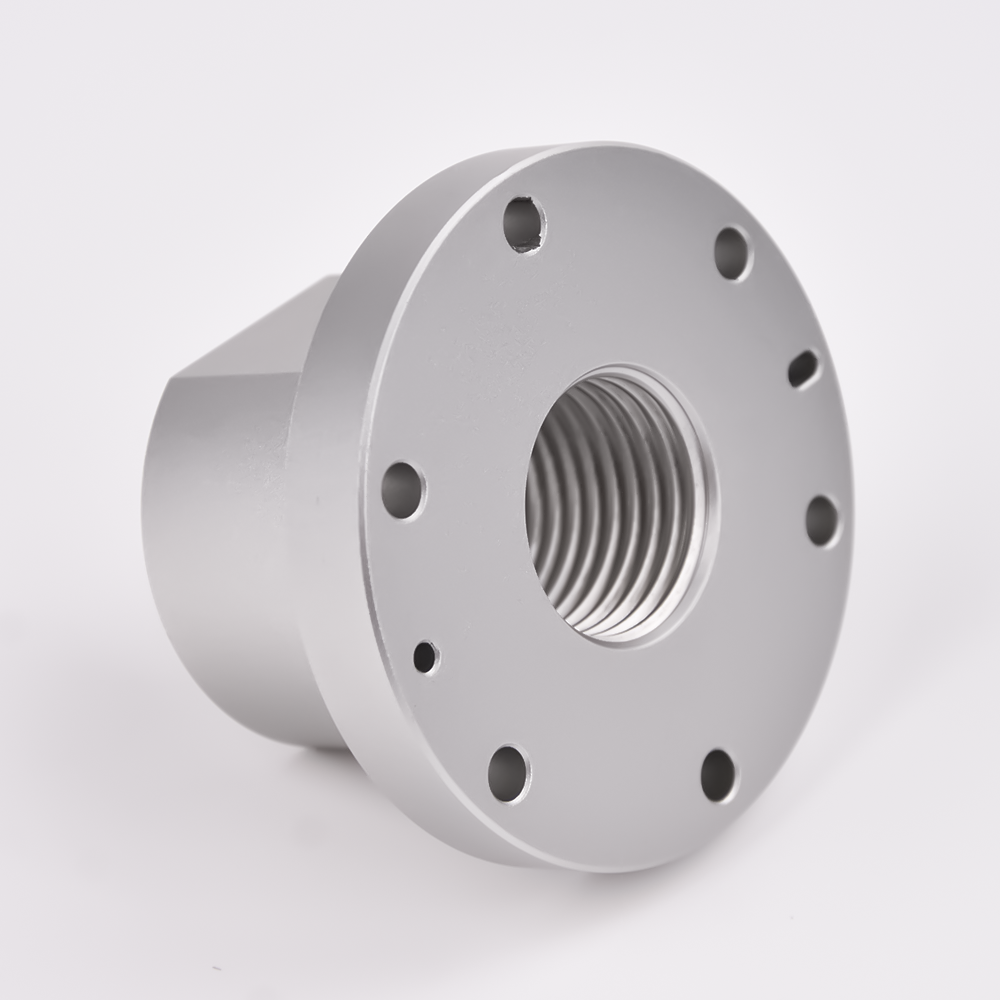

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical cutter head and a number of chip slots are usually called an end milling cutter or end milling cutter. It can move along different axes and is used to process long and narrow slots, grooves, contours, and so on. A milling machine is called a milling machine, a CNC milling machine is usually an exponential control machining center. Milling includes manual milling and CNC milling. Milling is carried out in the machining shop.

Titanium milling through CNC machining offers exceptional precision and adaptability for manufacturing complex, three-dimensional parts with intricate contours and tight tolerances. This process enhances production efficiency and automation while ensuring stable and reliable quality, even for components difficult to machine with conventional tools. The inherent strength and lightweight nature of titanium combined with advanced CNC milling capabilities enables the creation of customized, high-performance parts suitable for demanding applications.

Our Titanium CNC Milling Service is backed by a highly skilled team of engineers and technicians with extensive expertise in precision complex parts manufacturing. Leveraging advanced CNC technology and years of industry experience, our team ensures exceptional accuracy, consistency, and quality in every project. Committed to innovation and continuous improvement, we meticulously optimize every process to meet stringent specifications. Our collaborative approach and strong problem-solving abilities empower us to deliver customized solutions that drive client success. With a focus on reliability and excellence, our team is the cornerstone of providing robust, high-performance titanium components that exceed expectations.

Our Titanium CNC Milling Service is backed by a highly skilled team of precision engineers and machinists with extensive expertise in complex part manufacturing. Combining advanced CNC technology with deep material knowledge, our team ensures unparalleled accuracy, consistency, and efficiency. Their dedication to quality control and innovative problem-solving guarantees parts that meet the most demanding specifications. With a collaborative approach and continuous training, our team drives excellence from prototyping to full production, delivering reliable, high-performance titanium components that empower your projects. Trust our strong team foundation to transform your intricate designs into flawless, ready-to-use parts.

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical cutter head and a number of chip slots are usually called an end milling cutter or end milling cutter. It can move along different axes and is used to process long and narrow slots, grooves, contours, and so on. A milling machine is called a milling machine, a CNC milling machine is usually an exponential control machining center. Milling includes manual milling and CNC milling. Milling is carried out in the machining shop.

1, parts processing adaptability, flexibility, can process the contour shape is particularly complex or difficult to control the size of the parts, such as mold parts, shell parts, and so on.

2, can process ordinary machine tools can not process or difficult to process parts, such as mathematical model described by the complex curve parts and three-dimensional space surface parts.

3, can process a clamping positioning, need to carry out multi-process processing parts.

4, high processing accuracy, stable and reliable processing quality.

5, a high degree of production automation, can reduce the operator's labor intensity. Conducive to production management automation.

6, high production efficiency.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.