The main movement of the CNC stainless steel turned parts supplier is the rotating movement of the spindle, and the processing type is mainly the rotary parts. Rotary parts are divided into three types: bushing, wheel, and complex shape. The distinction between bushing and wheel parts lies in the length-diameter ratio. Generally, the parts with a length-diameter ratio greater than 1 are called bushing parts; Parts with an aspect ratio less than 1 are called wheel parts

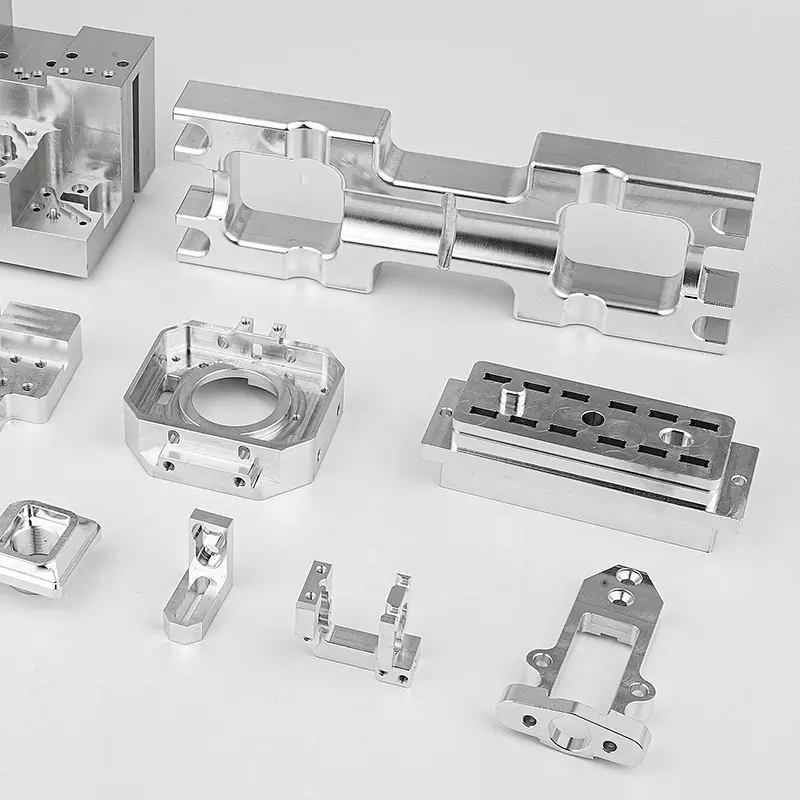

Our Stainless Steel CNC Turned Parts are crafted with precision and accuracy to ensure top-quality components for machinery. As a trusted supplier, we guarantee durability and longevity in our products, giving customers peace of mind in their equipment's performance. With superior materials and expert craftsmanship, our CNC turned parts deliver exceptional strength and reliability in demanding industrial applications.

Our team at Stainless Steel CNC Turned Parts Supplier is our greatest strength. With years of experience and expertise in the industry, our highly skilled professionals work together seamlessly to deliver top-quality products and exceptional customer service. From our engineers who design precision parts to our machinists who flawlessly execute the manufacturing process, every member of our team plays a crucial role in ensuring the success of our products. With a strong emphasis on collaboration, innovation, and dedication, we take pride in our team's ability to consistently meet and exceed customer expectations. Trust in our team to provide you with the best stainless steel CNC turned parts on the market.

At our Stainless Steel CNC Turned Parts Supplier, our team strength lies in our highly skilled and experienced staff who are dedicated to delivering top-quality products to our customers. Our team of expert machinists, engineers, and quality control specialists work together seamlessly to ensure precision, accuracy, and consistency in every part we produce. With a strong emphasis on communication, collaboration, and continuous improvement, our team is committed to meeting and exceeding customer expectations. Trust in our team's expertise and dedication to provide you with the best stainless steel CNC turned parts for your needs.

The type of partly processed by CNC turning

The main movement of the CNC turning is the rotating movement of the spindle, and the processing type is mainly the rotary parts. Rotary parts are divided into three types: bushing, wheel, and complex shape. The distinction between bushing and wheel parts lies in the length-diameter ratio. Generally, the parts with a length-diameter ratio greater than 1 are called bushing parts; Parts with an aspect ratio less than 1 are called wheel parts

1, the main object of CNC lathe processing

CNC lathes have high machining accuracy and can be used for linear and circular interpolation, some advanced CNC devices have some non-circular curve interpolation functions and can automatically change speed in the process of machining, according to the characteristics of CNC lathes, the following parts are the most suitable for CNC turning

2. Rotary parts with high precision requirements

CNC lathes can process parts that require high precision of bus straightness, roundness, cylindricity, and other shapes. For arcs and other curvy profiles, the shape produced is very close to the geometry required on the drawing. In some cases, you can use a car instead of a mill

3. Rotary parts with particularly complex contour shapes

Because the CNC lathe has the function of linear and circular interpolation, some advanced CNC devices have some non-circular curve interpolation function, so you can turn the shape of complex rotary parts composed of any straight line and plane curve, and difficult to control the size of the parts such as the shell parts with the closed inner forming surface, etc. This is the traditional lathe can not compare with the advantages

4. Rotary parts with high surface roughness requirements

Some CNC lathes have the function of constant speed cutting, which can process the parts with small but uniform surface roughness. When turning the cone and end face on the ordinary lathe, the surface roughness after turning is not consistent because of the constant speed. By using the constant speed-cutting function of the CNC lathe, the optimal linear speed can be selected to cut the cone and end face, so that the machining surface roughness is small and consistent. Numerical control car

Cutting is also suitable for turning parts with different surface roughness requirements. The roughness value requires the large part to choose the large feed, and the small part to choose the small feed.

5. Rotary parts with special threads

CNC lathe can not only turn any equal lead straight, conical, and end screw threads, and can increase the lead, reduce the lead and the requirements of smooth transition between the lead and the variable lead threads, and also can car high precision modular spiral parts (such as cylindrical, circular worm) and end (disc) spiral parts. CNC lathes can be equipped with precision thread cutting function, using carbide forming tool and higher revolution, so the turning out of the thread precision is high, and the surface roughness is small

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.