Sheet metal bending is the metal plate through the pressure equipment and special mold, the flat sheet into a three-dimensional processing process called bending. Due to different materials, thickness, length, the width of the plate, and the shape of different shapes and angles, so there are different tonnage and sizes of the bending machine pressure equipment, with different heights, shapes, and V amplitude sizes of the upper and lower die with its special shape of the special mold.

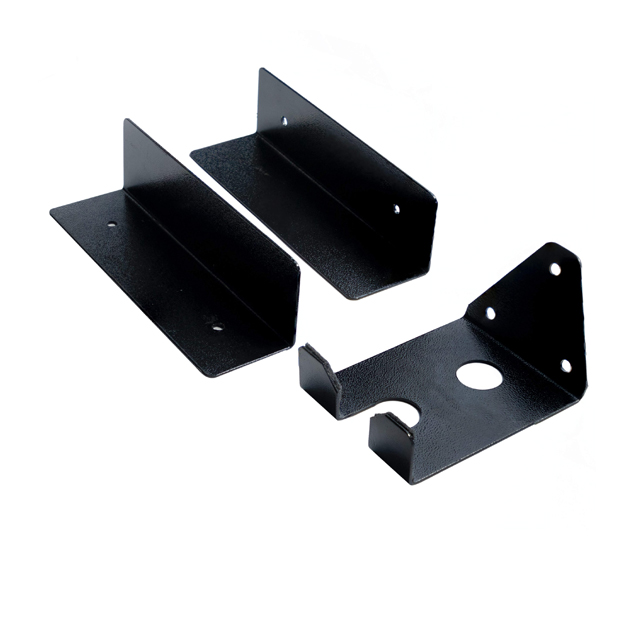

This metal bending service offers precise custom sheet metal bending and fabrication, ensuring high-quality, durable components tailored to exact specifications. Utilizing advanced machinery and skilled craftsmanship, it provides versatility for complex designs while maintaining consistent accuracy and strength. Key advantages include rapid turnaround, enhanced structural integrity, and the ability to produce both small and large-scale projects with exceptional precision.

Our Metal Bending Service is powered by a highly skilled team of expert fabricators dedicated to precision and quality. With extensive experience in custom sheet metal bending, our professionals leverage advanced technology and deep industry knowledge to deliver accurate, durable, and complex metal shapes tailored to your specifications. Our team’s commitment to innovation and meticulous craftsmanship ensures every project meets stringent quality standards, enhancing product reliability and performance. By combining technical expertise with collaborative problem-solving, we provide efficient, flexible solutions that add value and support your business success. Trust our team strength for unmatched precision fabrication and exceptional customer service.

Our Metal Bending Service is backed by a highly skilled team of experts dedicated to precision and quality. With years of combined experience in custom sheet metal bending and fabrication, our professionals harness advanced techniques and state-of-the-art equipment to ensure every project meets exact specifications. The team’s technical expertise, paired with a commitment to innovation and efficiency, guarantees reliable and consistent results. Their collaborative approach and attention to detail empower us to handle complex designs and tight deadlines, delivering exceptional value. Trust our strong, capable team to transform your metal bending needs into flawless, durable solutions.

Sheet metal bending is the metal plate through the pressure equipment and special mold, the flat sheet into a three-dimensional processing process called bending. Due to different materials, thickness, length, the width of the plate, and the shape of different shapes and angles, so there are different tonnage and sizes of the bending machine pressure equipment, with different heights, shapes, and V amplitude sizes of the upper and lower die with its special shape of the special mold.

Bending processing is divided into three categories: partial bending, dense bending, and embossing bending.

Part of the bending is 88 degrees; The following upper die, V= 12T (V represents the width of the slot, T represents the thickness of the material) of the lower die for right Angle, obtuse bending method. Close bending is 90 degrees; On the Right Angle and the obtuse bending method. Close bending selection V=6~ 12T. Embossing bending is 90 degrees; The upper die for right-angle bending. (is a standard right-angle bending) embossing bending die selection V=5~ 6T.

At present, there are many kinds of bending machines for sheet metal processing, which can be divided into mechanical (servo motor) and hydraulic types according to the way of rotation. The control system can be divided into simple manual bending machines, ordinary domestic digital positioning bending machines, and process control digital full-function bending machines. According to the action, the part can be divided into 4 axes, 8 axes, and 12 axes bending machines.

Sheet metal fabrication as the name implies is to uses sheet metal processing according to the demand to do needed items. There are a computer case cabinet, TV backplane, car shell, air conditioner shell, terminal integrated case, charging pile box, and so on.

1. Blanking:

There are a variety of blanking methods, refer to the workpiece after laser cutting or CNC punch cutting, shearing machine process. CNC blanking and laser cutting blanking can be used for thick and complex plate workpieces; the Shearing machine can be cut out of the larger shape of the workpiece length and width size; the Punch press can batch use punch press will workpiece shape and hole processing.

2, smoke hole

Hole pumping also called flanging, refers to the use of a die in the ordinary press or other stamping equipment on the workpiece to form a round hole edge up the process. Is in the pre-punch hole into a specified size the hole, so that the workpiece can tap teeth with more strength, generally used in the thickness of 1.5mm plate on the workpiece.

3, pressure riveting

Generally refers to the use of punch or hydraulic riveting machine riveting studs, riveting nuts, riveting screws, and other firmly riveting pressure on the workpiece process.

4, bending

Bending is the process of forming the workpiece by the bending machine with the bending bed and the related bending mold, which can strengthen the strength of the workpiece.

5, welding

Common welding processing types are two protection welding, argon arc welding, electric welding, robot welding, touch welding, etc., the process is mainly to two or more two parts together, to achieve the purpose of finished products or assembly accessories processing; Or the edge seam of a single part needs to be welded so that the bending edge is precise to increase the strength of the folding.

6, surface treatment

The surface treatment has phosphating skin film spraying powder, electroplating colorful zinc, chromate, paint, oxidation, and so on. After phosphating skin film, the workpiece can be electrostatic powder spraying, which is suitable for cold-rolled sheets and galvanized sheets. Electroplating colorful zinc is generally used for surface treatment of cold-rolled plates and machined parts; Chromate and oxidation are generally used for surface treatment of aluminum and aluminum profiles. Surface treatment is to make the sheet metal parts as a whole look beautiful and play a protective role in themselves, the specific surface treatment is based on customer material requirements.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.