The content of laser cutting processing technology can be roughly combed as follows: laser removal, such as laser drilling, etc.; Laser connection; Such as metal laser welding machine; Laser surface modification materials, such as laser quenching and tempering treatment (laser hardening primer, laser remelting, laser cladding); Laser production and manufacturing of new materials, such as laser calcination, laser preparation of polymer materials;

This cutting-edge laser cutting technology allows for rapid prototyping of products with incredible precision and speed. With the ability to create intricate designs and complex shapes, this technology opens up endless possibilities for product development. The high-quality results produced by this system give brands a competitive edge in the market.

At Laser Cutting Technology, we serve as your go-to solution for rapid prototyping needs. Our cutting-edge technology offers precision and efficiency, allowing for quick turnaround times on projects. With a wide range of materials that can be cut, we cater to various industries and applications. Our experienced team ensures top-notch quality and attention to detail in every project we undertake. We prioritize customer satisfaction and strive to exceed expectations with our seamless operations. Trust us to bring your designs to life with speed and accuracy. Choose Laser Cutting Technology for all your prototyping needs.

At Laser Cutting Technology, we serve as leaders in rapid prototyping solutions. Our state-of-the-art technology allows us to quickly and accurately produce prototypes for a wide range of industries. With our expertise in e-commerce product operations, we are dedicated to providing top-quality service to our customers. From concept to creation, we are committed to helping you bring your ideas to life efficiently and cost-effectively. Trust us to deliver on our promise of precision, speed, and innovation. Let us serve you by making your prototyping process seamless and successful. Partner with us for all your rapid prototyping needs.

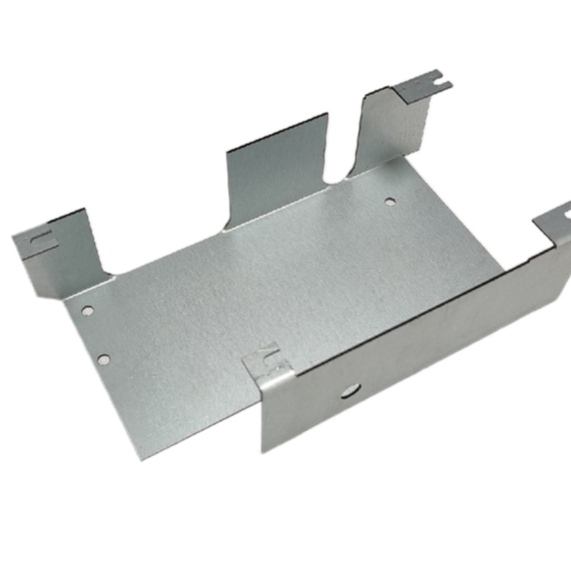

Laser-cutting molding technology

The content of laser cutting processing technology can be roughly combed as follows: laser removal, such as laser drilling, etc.; Laser connection; Such as metal laser welding machine; Laser surface modification materials, such as laser quenching and tempering treatment (laser hardening primer, laser remelting, laser cladding); Laser production and manufacturing of new materials, such as laser calcination, laser preparation of polymer materials; Laser parts processing, such as laser parts rapid prototyping technology production and processing.

Main equipment and introduction: Rapid prototyping and laser cutting training room have 3D printing machine tools and laser cutting machine tools. The laser cutting machine uses laser principle technology to process parts, and 3D printing uses rapid prototyping methods to complete product design and sample processing, which greatly improves the speed of trial production of new products and product replacement efficiency.

Among them, are laser cutting processing connection, laser surface modification materials, laser manufacturing new materials, and laser parts internal organizational structure transformation. It should be emphasized that some processing methods are not only surface-modified materials but also towards the rapid production of metal parts by laser. That's what laser cladding means, for example.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.