Customers who have used laser cutting technology know that laser cutting processing technology is a kind of use of laser beam on the surface of the accessories continuous movement to achieve, and this kind of work in the laser beam has good directivity but also has a good correlation, its cutting ability density is good, is also very large.

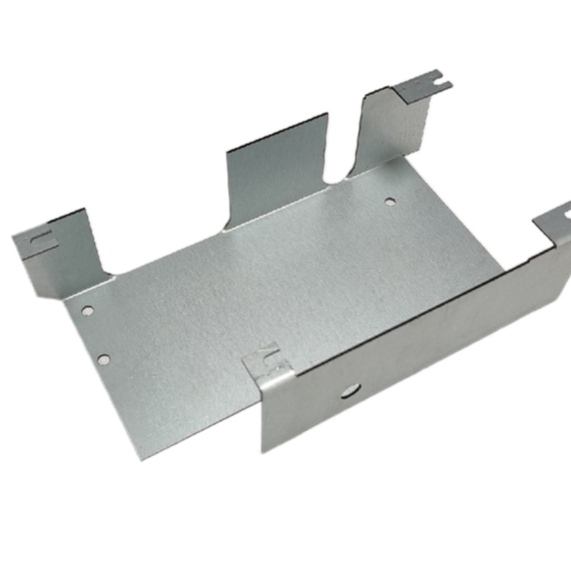

Our laser cut sheet metal parts are produced using cutting-edge laser cutting technology, ensuring high quality and precision in each piece. The laser beam can be focused on a small spot of light, allowing for fast cutting speeds without deformation. With the ability to control energy density and perform local operations, our laser cutting process provides adaptability, sensitivity, and exceptional cutting capabilities unmatched by traditional methods.

At our company, we specialize in utilizing cutting-edge laser cutting technology to produce precision metal parts for various industries. With a focus on quality and efficiency, we serve our customers with cutting-edge solutions that meet their specific needs. Our team of experts is dedicated to delivering high-quality products that exceed expectations. From prototype development to full-scale production, we are committed to providing superior service and exceptional results. With our state-of-the-art equipment and skilled technicians, we ensure that every project is completed with precision and accuracy. Trust us to serve you with the best in laser cutting technology for your metal part needs.

At our company, we specialize in providing high-quality laser cutting technology for precision metal parts. Our team of experts is dedicated to serving our customers with precision, efficiency, and attention to detail. With state-of-the-art equipment and a commitment to excellence, we ensure that each part is cut with accuracy and precision. Whether you need custom metal parts for a specific project or ongoing production needs, we are here to serve you. Trust us to deliver top-notch products that meet your exact specifications and exceed your expectations. Experience the difference with our dedication to serving you with the best in laser cutting technology.

Customers who have used laser cutting technology know that laser cutting processing technology is a kind of use of laser beam on the surface of the accessories continuous movement to achieve, and this kind of work in the laser beam has good directivity but also has a good correlation, its cutting ability density is good, is also very large.

First, laser cutting characteristics:

1, in the cutting quality, is high quality, fine.

This kind of laser equipment used to cut the laser beam can be focused on a small spot of light so that the laser cutting machine to achieve a high use of power, thus cutting speed is fast, with very high precision, but also to ensure that the workpiece will not appear deformation.

2, strong adaptability, high sensitivity.

This cutting method adopts the hot cutting technology, when cutting the affected area is small, will not have a large impact. Another advantage is that it can process some non-metal, of course, this is also what other laser-cutting equipment can not do.

3, large energy, can control the change of its density, and can also be a local operation.

This kind of laser has good control performance, can freely control the laser cutting machine running track, and any hard material can be made corresponding cutting. With these gadgets, we can also cut locally.

Two, the laser cutting process has the following kinds:

1. The fusion cutting method is to irradiate the laser incident speed of light into the plate. When the laser power reaches a certain critical value, the local area will be melted, so as to achieve the cutting effect.

2, vaporization cutting with high power density laser to heat processing materials, avoid the melting caused by heat conduction and the formation of hanging slag burr, part of the material evaporates after evaporation, the edge is beautiful.

3. Oxidation cutting refers to the hot processing caused by the oxygen blowing and the laser lighting in the nozzle, and the intense chemical reaction of oxygen occurs; For brittle materials vulnerable to heat damage, high-speed controlled cutting can be achieved by heating laser beam, which leads to the large thermal gradient in the area, serious mechanical deformation, and material cracking, also known as controlled fracture cutting.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.