The content of laser cutting processing technology can be roughly combed as follows: laser removal, such as laser drilling, etc.; Laser connection; Such as metal laser welding machine; Laser surface modification materials, such as laser quenching and tempering treatment (laser hardening primer, laser remelting, laser cladding); Laser production and manufacturing of new materials, such as laser calcination, laser preparation of polymer materials;

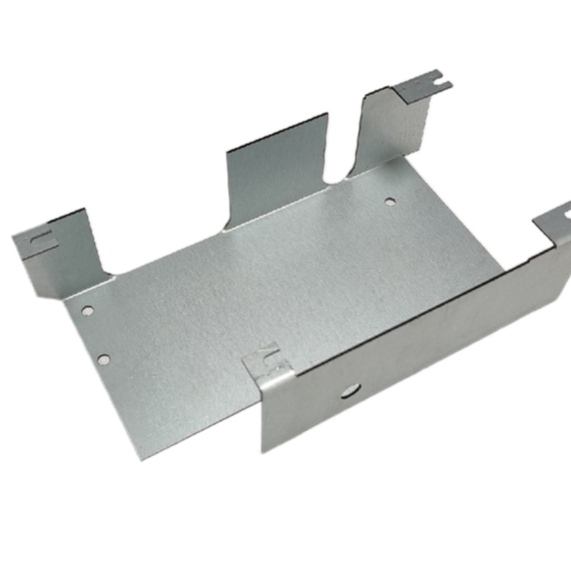

As experienced laser cutting parts suppliers, this product leverages advanced laser cutting and rapid prototyping technologies to deliver precise, high-quality metal components with enhanced surface modification and internal structural transformation. Its core attributes include laser removal, welding, and cladding processes that enable efficient production and improved material performance, while rapid prototyping accelerates design iteration and trial manufacturing. The product’s unique integration of laser-based techniques ensures superior precision, durability, and customization, meeting diverse industrial applications with exceptional speed and reliability.

We serve businesses and innovators seeking precise, high-quality laser cutting and rapid prototyping for metal parts. Our expertise ensures accurate, efficient fabrication tailored to your unique specifications, supporting product development from concept to production. With advanced technology and skilled craftsmanship, we deliver durable, intricate components that meet strict industry standards. Whether you require small-batch prototypes or large-scale manufacturing, we prioritize speed, reliability, and cost-effectiveness to accelerate your project timeline. Partner with us for exceptional service, technical support, and solutions that empower your engineering and manufacturing needs, turning ideas into tangible, high-performance metal parts.

We serve businesses and innovators seeking precision and efficiency in metal fabrication. Specializing in laser cutting and rapid prototyping, we deliver high-quality, customizable metal parts with exceptional accuracy and fast turnaround times. Our expert team utilizes advanced technology to support various industries, from automotive to aerospace, ensuring each prototype meets exact specifications. Committed to reliability and innovation, we provide flexible solutions tailored to your unique project needs. Partner with us for seamless production, reduced lead times, and superior craftsmanship — empowering your product development with precision metal parts designed to accelerate your success.

Laser-cutting molding technology

The content of laser cutting processing technology can be roughly combed as follows: laser removal, such as laser drilling, etc.; Laser connection; Such as metal laser welding machine; Laser surface modification materials, such as laser quenching and tempering treatment (laser hardening primer, laser remelting, laser cladding); Laser production and manufacturing of new materials, such as laser calcination, laser preparation of polymer materials; Laser parts processing, such as laser parts rapid prototyping technology production and processing.

Main equipment and introduction: Rapid prototyping and laser cutting training room have 3D printing machine tools and laser cutting machine tools. The laser cutting machine uses laser principle technology to process parts, and 3D printing uses rapid prototyping methods to complete product design and sample processing, which greatly improves the speed of trial production of new products and product replacement efficiency.

Among them, are laser cutting processing connection, laser surface modification materials, laser manufacturing new materials, and laser parts internal organizational structure transformation. It should be emphasized that some processing methods are not only surface-modified materials but also towards the rapid production of metal parts by laser. That's what laser cladding means, for example.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.