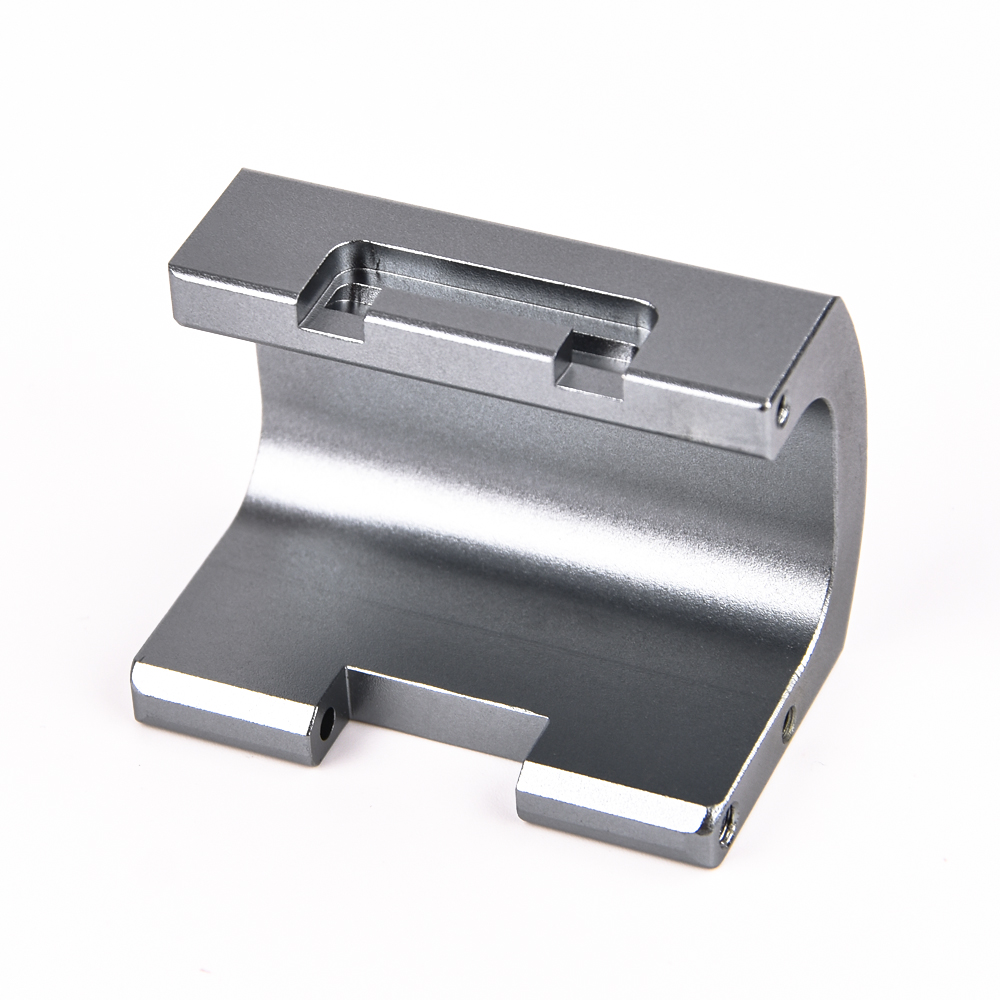

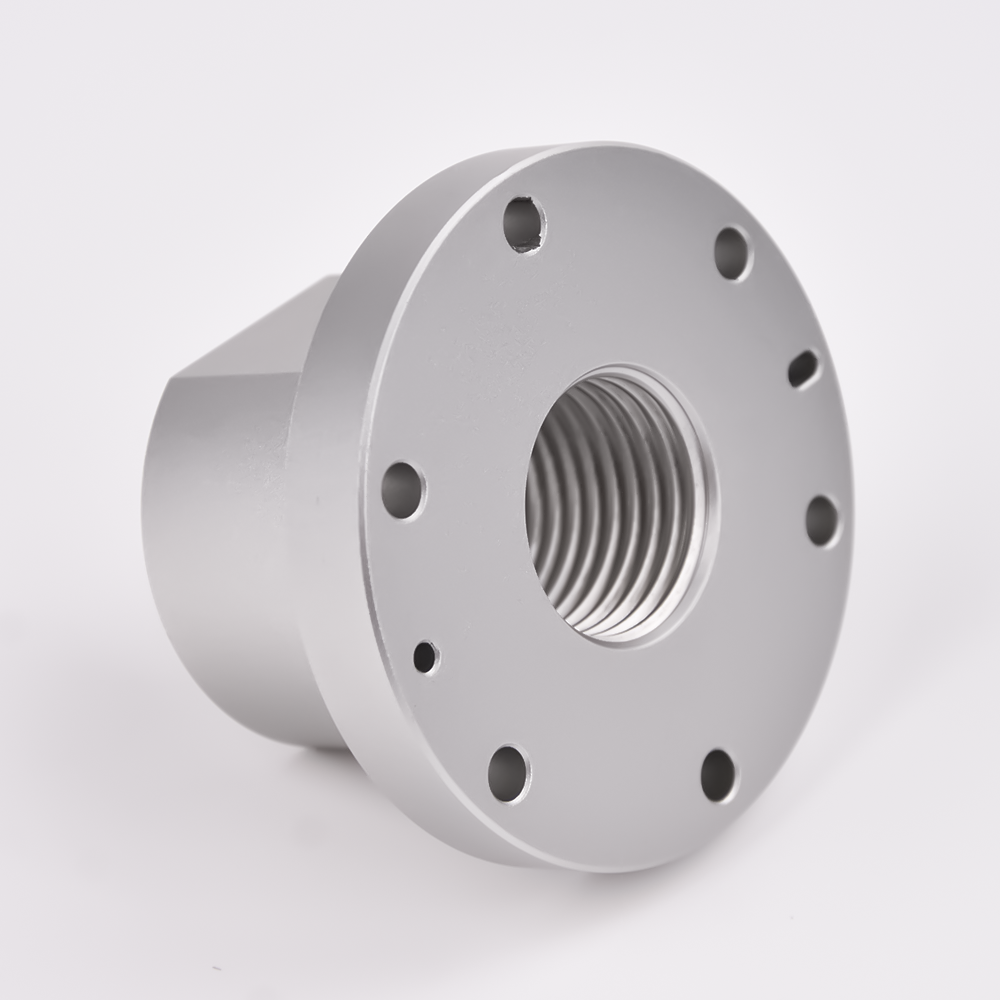

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical cutter head and a number of chip slots are usually called an end milling cutter or end milling cutter. It can move along different axes and is used to process long and narrow slots, grooves, contours, and so on. A milling machine is called a milling machine, a CNC milling machine is usually an exponential control machining center. Milling includes manual milling and CNC milling. Milling is carried out in the machining shop.

This High-Precision CNC Titanium Machining service is tailored for producing complex prismatic parts, leveraging both the core and extended attributes inherent in CNC milling technology. The process ensures meticulous adaptability and flexibility, allowing for the precise creation of intricate contour shapes and three-dimensional surfaces that are difficult to achieve with ordinary machines. With a high degree of automation, this technology not only enhances production efficiency but also maintains stable and reliable product quality, minimizing labor intensity and optimizing production management for quality control.

**Company Profile:**

At [Your Company Name], we specialize in high-precision CNC titanium machining for complex prismatic parts, standing at the forefront of the manufacturing industry. With decades of experience, our company combines cutting-edge technology and expert craftsmanship to deliver unmatched accuracy and quality. Our state-of-the-art facilities are equipped with advanced CNC machines, enabling us to handle intricate designs and maintain tight tolerances. We pride ourselves on our commitment to innovation, quality assurance, and customer satisfaction. Trusted by industries ranging from aerospace to medical devices, we are dedicated to providing bespoke solutions tailored to meet the specific needs of our clients.

[Company Name] is a leading provider of high-precision CNC titanium machining, specializing in complex prismatic parts. Our state-of-the-art facilities and cutting-edge technology ensure superior accuracy and quality in every component we produce. With a team of skilled engineers and technicians, we are dedicated to delivering innovative solutions that meet the unique needs of our clients across diverse industries. Our commitment to excellence is reflected in our rigorous quality control processes and sustainable manufacturing practices. Partnering with us means benefiting from unmatched expertise, timely delivery, and exceptional customer service. Choose [Company Name] for precision, reliability, and excellence in titanium machining.

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical cutter head and a number of chip slots are usually called an end milling cutter or end milling cutter. It can move along different axes and is used to process long and narrow slots, grooves, contours, and so on. A milling machine is called a milling machine, a CNC milling machine is usually an exponential control machining center. Milling includes manual milling and CNC milling. Milling is carried out in the machining shop.

1, parts processing adaptability, flexibility, can process the contour shape is particularly complex or difficult to control the size of the parts, such as mold parts, shell parts, and so on.

2, can process ordinary machine tools can not process or difficult to process parts, such as mathematical model described by the complex curve parts and three-dimensional space surface parts.

3, can process a clamping positioning, need to carry out multi-process processing parts.

4, high processing accuracy, stable and reliable processing quality.

5, a high degree of production automation, can reduce the operator's labor intensity. Conducive to production management automation.

6, high production efficiency.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.