Set up years ago, Bergek CNC is a professional manufacturer and also a supplier with strong capabilities in production, design, and R&D. stainless steel milling parts We have professional employees who have years of experience in the industry. It is them that provides high-quality services for customers all over the world. If you have any questions about our new product stainless steel milling parts or want to know more about our company, feel free to contact us. Our professionals would love to help you at any time.SHENZHEN BERGEK TECHNOLOGY CO., LTD. has established all-round after-sales service.

Product Description:

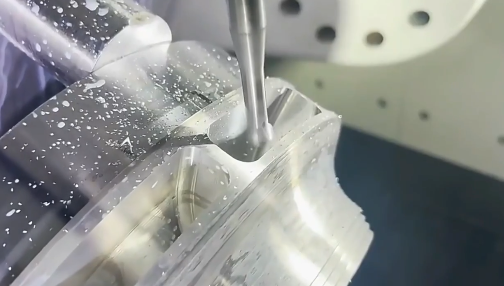

Stainless Steel CNC Milling Parts

Stainless steel provides excellent machinability, outstanding uniformity, and is corrosion and oxidation resistant, leading to longer product life and lower total cost of machined parts.

Key Benefits:

√ Corrosion resistance

√ Designed for improved machinability

√ Strong

√ Low cost

√ Quick part turn around

Stainless Steel CNC Milling Process: Step by Step

The stainless steel cnc milling process consists of various processes that are used to shape and size an unprocessed steel workpiece. Here's all the details of the steel milling process:

1. Workpiece Preparation: The procedure begins with the steel workpiece being prepared for milling. Surface cleaning, contaminants removal, and the proper clamping for holding the piece of metal during machining are all part of this process.

2. Tool selection: The appropriate steel milling tools are essential for successful steel milling. Tool selection is influenced by factors such as steel type, required cutting parameters, and the complexity of the machining operation.

3. Machine Setup: Once the workpiece and tools have been ready, set up milling machine. This includes altering machine settings such as spindle speed, feed rate, and depth of cut dependent on the needs of the milling operation.

4. Milling: After everything is in place, the milling process begins. Cutting tools remove excess material from the workpiece in an orderly fashion while following the specified tool path and cutting parameters. This process is repeated until the required shape and dimension are obtained.

5. Finishing: After cnc milling, the cnc milling steel component is finished by polishing, or coating to improve its surface finish and appearance. Quality control tests are performed to verify dimensional accuracy and standardization.

Bergek CNC Milling Service

CNC milling is a CNC machining service process that utilizes computer numerical control (CNC) machines to remove material from a workpiece. CNC milling is a reduction manufacturing process that uses 3-axis milling and 5-axis indexing to cut solid plastic and metal blocks into final parts. Our company specializes in providing high-quality CNC milling services for stainless steel components. We have a team of experienced professionals who use advanced technology to deliver precise and accurate results.

Advantages:

√ Advanced technology and equipment

√ Experienced professionals

√ A diverse range of sizes and shapes

√ The rigorous quality control process

√ Excellent customer service

Introduction:

Our company specializes in providing high-quality CNC milling

services for stainless steel components. We have a team of experienced

professionals who use advanced technology to deliver precise and accurate

results.

Company Overview:

We are a leading manufacturer of precision parts and

components, serving various industries such as aerospace, automotive, medical,

and defense. Our company has been providing CNC machining services for over a

decade and has a proven track record of delivering high-quality products.

Manufacturing Capability:

Our state-of-the-art facility is equipped with the

latest CNC milling machines that are capable of handling even the most complex

designs. We have the ability to manufacture parts and components in a wide range

of sizes and shapes, ensuring that we can meet the diverse needs of our

customers.

Quality Assurance:

At our company, we are committed to delivering products

that meet the highest standards of quality. We have a rigorous quality control

process that ensures that all components are thoroughly inspected before being

shipped to our customers. We also use only the highest-quality materials and

employ the latest manufacturing techniques to ensure that our products meet or

exceed our customers' expectations.

Service Experience:

We pride ourselves on providing excellent customer

service to our clients. Our team is always available to answer any questions or

concerns that our customers may have, and we work closely with them throughout

the manufacturing process to ensure that their needs are met.

Cooperation Model: We offer a range of cooperation models to suit the needs

of our customers. Whether our clients need a one-off order or ongoing

manufacturing support, we have the capability to provide customized solutions

that meet their needs.

Customized solutions to meet customer needs

In summary, our company is dedicated to providing high-quality CNC milling

services for stainless steel components. We have the experience, technology, and

expertise to deliver precise and accurate results that meet or exceed our

customers' expectations. We pride ourselves on providing excellent customer

service and customized solutions to meet the diverse needs of our clients.