The content of laser cutting processing technology can be roughly combed as follows: laser removal, such as laser drilling, etc.; Laser connection; Such as metal laser welding machine; Laser surface modification materials, such as laser quenching and tempering treatment (laser hardening primer, laser remelting, laser cladding); Laser production and manufacturing of new materials, such as laser calcination, laser preparation of polymer materials;

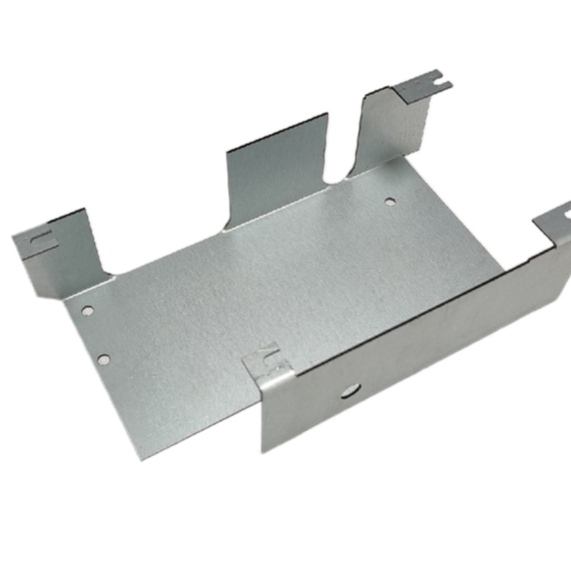

This product combines precision laser cutting technology with fast prototyping capabilities, ensuring rapid development and accurate customization to meet diverse project needs. Enhanced by advanced surface treatment, it delivers superior durability and an excellent finish that stands out in both functionality and aesthetics. Key features include high precision, quick turnaround times, customizable design options, and robust surface protection, making it ideal for a wide range of industrial and creative applications.

Our team’s exceptional strength lies in combining advanced engineering expertise with years of hands-on experience in laser cutting technology. We leverage cutting-edge prototyping capabilities to deliver precise, custom laser cut parts rapidly, ensuring your project moves from concept to reality without delay. Each member is skilled in advanced surface treatment techniques, guaranteeing superior finish quality and durability. Committed to innovation and customer satisfaction, our multidisciplinary team collaborates closely to meet complex specifications and offer tailored solutions. This cohesive expertise ensures reliability, speed, and excellence, making us your trusted partner for high-quality, custom laser cut components.

Our team combines extensive expertise in precision laser cutting with advanced prototyping techniques to deliver custom parts that meet the highest standards. With skilled engineers and state-of-the-art equipment, we ensure fast turnaround times without compromising quality. Our dedication to innovation and meticulous surface treatment processes enhances product durability and performance, providing clients with reliable solutions tailored to their specific needs. Committed to collaboration and continuous improvement, our team’s strength lies in blending technical proficiency with customer-focused service, making us your trusted partner for custom laser cut parts that accelerate development and drive success.

Laser-cutting molding technology

The content of laser cutting processing technology can be roughly combed as follows: laser removal, such as laser drilling, etc.; Laser connection; Such as metal laser welding machine; Laser surface modification materials, such as laser quenching and tempering treatment (laser hardening primer, laser remelting, laser cladding); Laser production and manufacturing of new materials, such as laser calcination, laser preparation of polymer materials; Laser parts processing, such as laser parts rapid prototyping technology production and processing.

Main equipment and introduction: Rapid prototyping and laser cutting training room have 3D printing machine tools and laser cutting machine tools. The laser cutting machine uses laser principle technology to process parts, and 3D printing uses rapid prototyping methods to complete product design and sample processing, which greatly improves the speed of trial production of new products and product replacement efficiency.

Among them, are laser cutting processing connection, laser surface modification materials, laser manufacturing new materials, and laser parts internal organizational structure transformation. It should be emphasized that some processing methods are not only surface-modified materials but also towards the rapid production of metal parts by laser. That's what laser cladding means, for example.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.