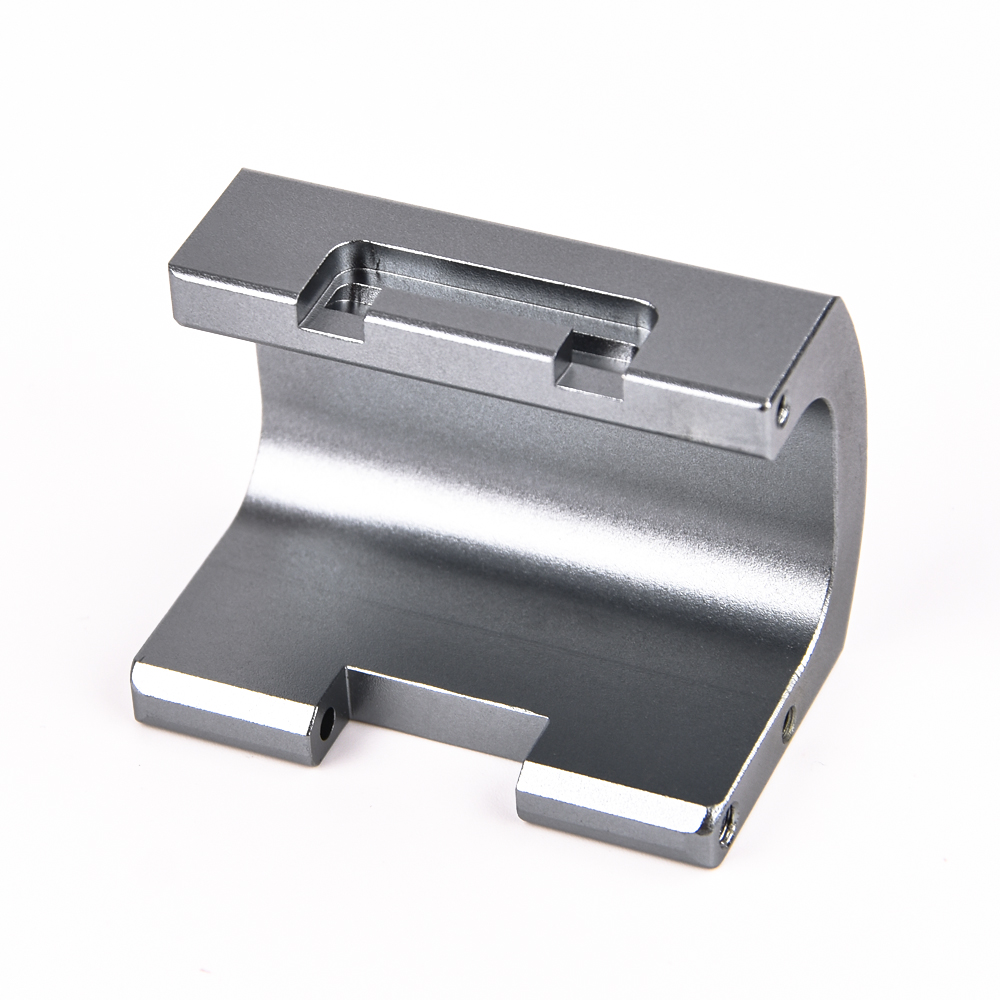

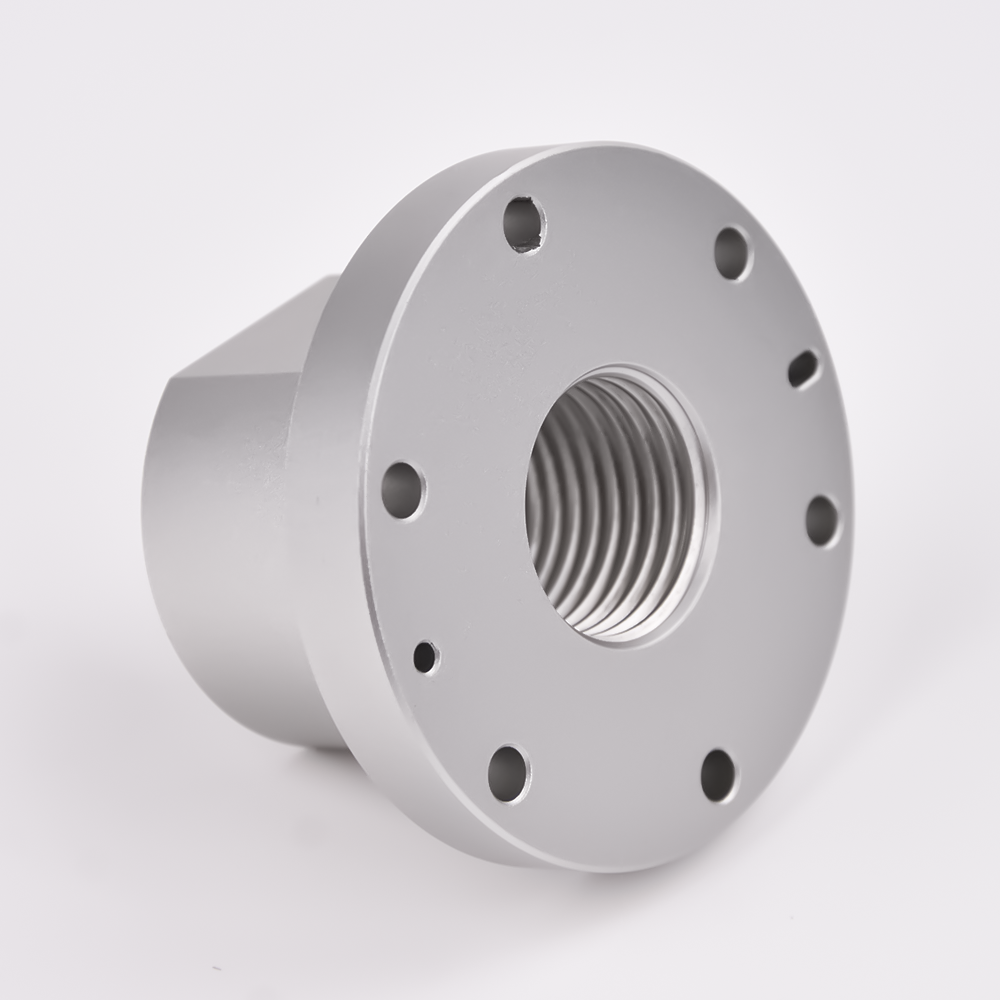

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical cutter head and a number of chip slots are usually called an end milling cutter or end milling cutter. It can move along different axes and is used to process long and narrow slots, grooves, contours, and so on. A milling machine is called a milling machine, a CNC milling machine is usually an exponential control machining center. Milling includes manual milling and CNC milling. Milling is carried out in the machining shop.

CNC titanium machining offers exceptional precision and flexibility in producing complex, contour-shaped parts that are difficult to achieve with conventional methods, including mold and shell components. This service ensures high processing accuracy and stable quality through automated multi-axis control, enabling efficient, multi-process machining with minimal operator intervention. The robust structural design of CNC milling centers allows for processing intricate three-dimensional surfaces and long, narrow slots, delivering reliable, high-efficiency titanium part fabrication.

Our CNC Titanium Milling Service is backed by a highly skilled team of engineers and machinists with extensive expertise in precision and complex part machining. Leveraging advanced technology and years of industry experience, our team ensures exceptional accuracy, surface finish, and durability in every project. Committed to continuous innovation and quality control, they collaborate closely with clients to meet unique specifications and tight tolerances. This strong team foundation guarantees reliable delivery, optimized production efficiency, and superior product performance, making us a trusted partner for titanium machining solutions that demand excellence and precision.

Our CNC Titanium Milling Service is backed by a highly skilled team of engineers and machinists with extensive experience in precision and complex part machining. Combining advanced technical expertise with a deep understanding of titanium’s unique properties, our team ensures impeccable accuracy and consistent quality in every project. Emphasizing collaboration, continuous training, and innovation, they harness cutting-edge CNC technology to meet tight tolerances and challenging specifications. Their commitment to excellence and problem-solving drives efficiency and reliability, delivering superior results that empower your product development and manufacturing processes. Trust our expert team to transform your complex titanium components into precise, high-performance solutions.

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical cutter head and a number of chip slots are usually called an end milling cutter or end milling cutter. It can move along different axes and is used to process long and narrow slots, grooves, contours, and so on. A milling machine is called a milling machine, a CNC milling machine is usually an exponential control machining center. Milling includes manual milling and CNC milling. Milling is carried out in the machining shop.

1, parts processing adaptability, flexibility, can process the contour shape is particularly complex or difficult to control the size of the parts, such as mold parts, shell parts, and so on.

2, can process ordinary machine tools can not process or difficult to process parts, such as mathematical model described by the complex curve parts and three-dimensional space surface parts.

3, can process a clamping positioning, need to carry out multi-process processing parts.

4, high processing accuracy, stable and reliable processing quality.

5, a high degree of production automation, can reduce the operator's labor intensity. Conducive to production management automation.

6, high production efficiency.

Copyright © 2026 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.