The metal bending process is a fundamental manufacturing technique that involves shaping metal sheets and bars into a desired form. This process is used in a wide range of industries, including construction, aerospace, automotive, and electronics. In this article, we will discuss the basics of the metal bending process, including the techniques, tools, and materials involved.

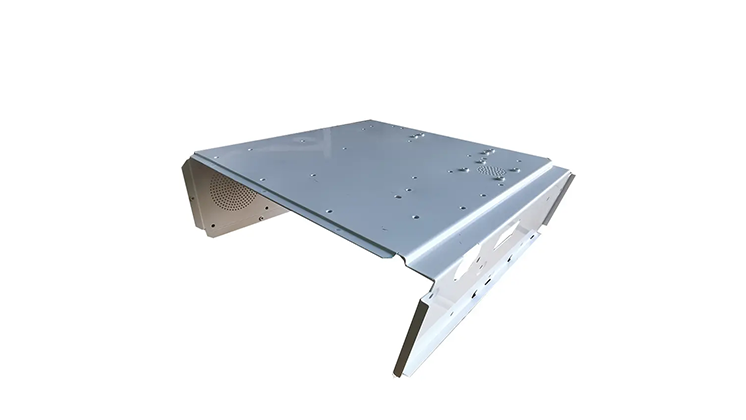

CNC sheet metal bending service delivers precise and customizable metal fabrication by utilizing advanced bending techniques such as roll bending, press bending, and hot bending to achieve complex shapes with high accuracy. This service supports a variety of materials including steel, aluminum, and copper, ensuring durability, corrosion resistance, and functional performance tailored to diverse industry needs. The core structural feature of CNC sheet metal bending lies in its use of automated bending machines and specialized dies, which enable consistent quality and efficient production for prototyping, small batch, or mass manufacturing.

Our company specializes in CNC sheet metal bending services, delivering precise and custom metal fabrication tailored to your exact specifications. With advanced technology and a skilled engineering team, we ensure high-quality, consistent results for diverse industries. Committed to innovation and reliability, we prioritize customer satisfaction through timely delivery and excellent support. Our comprehensive capabilities, strict quality control, and flexible production processes make us a trusted partner for your metal fabrication needs. By combining expertise with cutting-edge equipment, we help clients achieve superior structural integrity and design accuracy in every project.

Our company specializes in CNC sheet metal bending, delivering precise and custom metal fabrication solutions tailored to your unique specifications. With advanced technology and skilled craftsmanship, we ensure exceptional accuracy, durability, and consistency in every project. Committed to innovation and customer satisfaction, we provide reliable services that support diverse industries, from automotive to electronics. Our streamlined processes, quality control, and timely delivery reflect our dedication to excellence and long-term partnerships. Choose us for expert metal forming services that combine cutting-edge machinery with deep industry experience, helping you achieve superior results with efficiency and confidence.

A Guide to Understanding the Basics

The metal bending process is a fundamental manufacturing technique that involves shaping metal sheets and bars into a desired form. This process is used in a wide range of industries, including construction, aerospace, automotive, and electronics. In this article, we will discuss the basics of the metal bending process, including the techniques, tools, and materials involved.

There are several techniques used in metal bending, including:

Roll bending: This technique involves passing a metal sheet or bars through a series of rollers, which apply pressure and gradually bend the metal into the desired shape.

Press bending: In this technique, a metal sheet or bar is placed between two dies and a press applies force to bend the metal to the desired angle.

Hot bending: This technique involves heating the metal to a high temperature and then bending it while it is still hot. This technique is used for metals that are difficult to bend at room temperature.

Tools

The tools used in metal bending include:

Bending machines: These machines are used to apply force and pressure to the metal during the bending process. They come in various sizes and configurations, depending on the size and thickness of the metal being bent.

Dies: These are specialized tools that are used to shape the metal into a specific form. They come in various shapes and sizes, depending on the desired outcome.

Heating equipment: Hot bending requires specialized heating equipment, such as a furnace or torch, to heat the metal to the required temperature.

Materials

The most commonly used materials in metal bending include:

Steel: This is the most commonly used metal in the metal bending process due to its strength and durability.

Aluminum: This metal is lightweight and has good corrosion resistance, making it a popular choice in the aerospace and automotive industries.

Copper: This metal is highly conductive and is often used in electronics and electrical applications.

Conclusion

The metal bending process is a critical manufacturing technique used in various industries worldwide. Understanding the basics of the metal bending process, including the techniques, tools, and materials involved, can help you make informed decisions when choosing a metal bending service provider or when considering the purchase of a bending machine. Whether you need to bend metal sheets or bars for construction, automotive, aerospace, or electronics applications, the metal bending process can help you achieve your desired results.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.