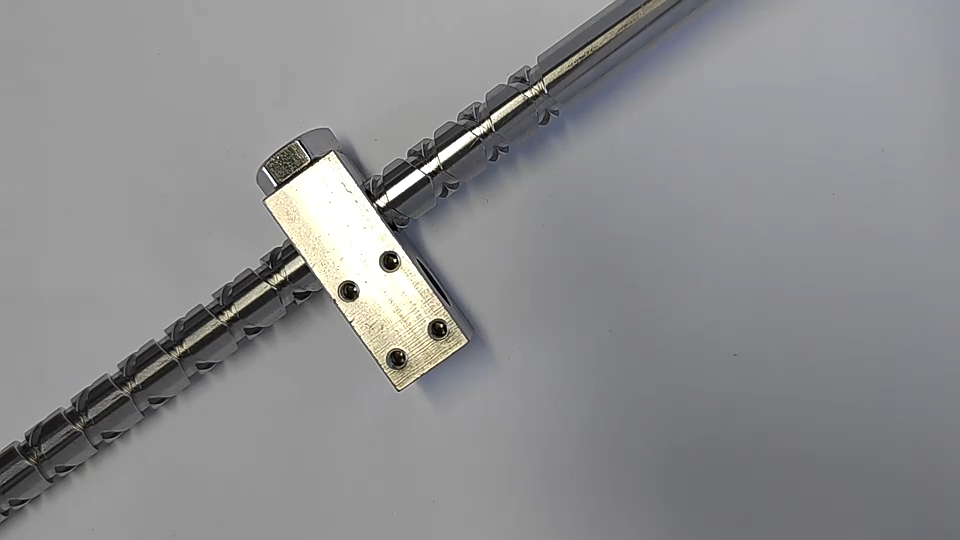

The self-reversing screw product does not require the driven screw to change its direction of rotation to enable the nut to return to its original start position. The reciprocated bi-directional movement is achieved by using a follower blade in the nut, the self-reversing screw product does not require the driven screw to change its direction of rotation to enable the nut to return to its original start position. The reciprocated bi-directional movement is achieved by using a follower blade in the nut, that is matched to the particular groove width and screw turn round on the screw.at is matched to the particular groove width and screw turn round on the screw.

The self-reversing screw product does not require the driven screw to change its direction of rotation to enable the nut to return to its original start position. The reciprocated bi-directional movement is achieved by using a follower blade in the nut, that is matched to the particular groove width and screw turn round on the screw.

Bergek is a world-class manufacturing service provider in Shenzhen. We got advanced equipment to provide all-around customized products for manufacturers around the world, focusing on CNC processing and sheet metal processing. The self reversing lead screws take about 5 - 7 weeks to be manufactured. They can be created in just about any mild steel, stainless steel.

Bergek CNC machining serivice case - self reversing screw

Each tapping screw consists of a head, a rod, and a rod end. Each tapping screw has four elements: head shape, screw type, thread type, and end form.

1. Head shape (head type)

Various head shapes. There is a round head (semicircle head), flathead, round head (with pad), flathead flange (with pad), pan head flange (with pad), countersunk head, countersunk head, cylindrical head, spherical cylindrical head, horn head, hexagonal head, hexagonal flange head, hexagonal flange head (with pad) head.

2. Pulling mode (trough type)

Wrench mode refers to the way to twist the screw head when installing and fastening screws. The basic method has two kinds: outside pull and inside pull. In general, the torque of the outer wrench is greater than that of any form of inner wrench (inner groove). Screw: hexagonal, hexagonal flange, hexagonal flange, hexagonal flower shape, etc.; Screw inside: a word groove, cross groove H, cross groove Z, cross groove F, square groove, compound groove, inner spline, inner hexagon flower shape, inner triangle, inner hexagon, inner 12 Angle, clutch groove, six-leaf groove, high torque cross groove, etc.

3. Thread type

There are many kinds of threads, including self-tapping thread (wide thread), machine thread (ordinary thread), drywall thread, fiberboard thread, and other special threads. In addition, threads can be divided into single lead (single head), double lead (double head), multiple leads (multi-head), and high and low tooth double head threads.

4. End Style (tail)

The end style mainly has a cone end and a flat end. However, grooves, grooves, notches, and orbits similar to the shape of a drill can be machined at the end of the screw-in portion, depending on the use. In some standards, cone end or flat end also have different forms, such as round head end.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.