Since established, Bergek CNC aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product cnc turning brass parts or our company, just contact us.

New Delhi: Friday heralds a double blow to insufficient power supply and strong demand in the summer: starting from Thursday-At midnight on Friday, State Hydro stopped supplying Reliance\'s BSES Rajdhani and BSES Yamuna discoms, allegedly at the highest level in the capital because of arrears in paymentUsed to power 5,330 MW. All parts of south Delhi and Central and West Germany were cut off.

After reflux, through-The hole assembly is welded on the board and the final result is as follows: the light shield 7 Digikey material list can be downloaded here. This document can be uploaded to Digikey in order to easily get all the components needed to assemble your own light shield 7. This bill of materials does not include parts ordered directly from microchips-

The last one is the actual laser center point. You need to check this every time you want to laser carve something. If the dust gathers on it, you may lose power or even focus at all. Lense is an artifact that helps you finally focus on the laser. The more dust this is, the more machines your machine has broken parts.

Stepping Motor Drives 3mm GT2 belt through 15-Aluminum tooth pulley. At the end of each axis is a ball-raced 15-The tooth returns to the pulley. The belts are clamped on movable parts, so they move with the rotation of the stepping motor. The laser diode module has a black housing with an integrated thermal-16mm anodizedsink, a screw-in clamp-

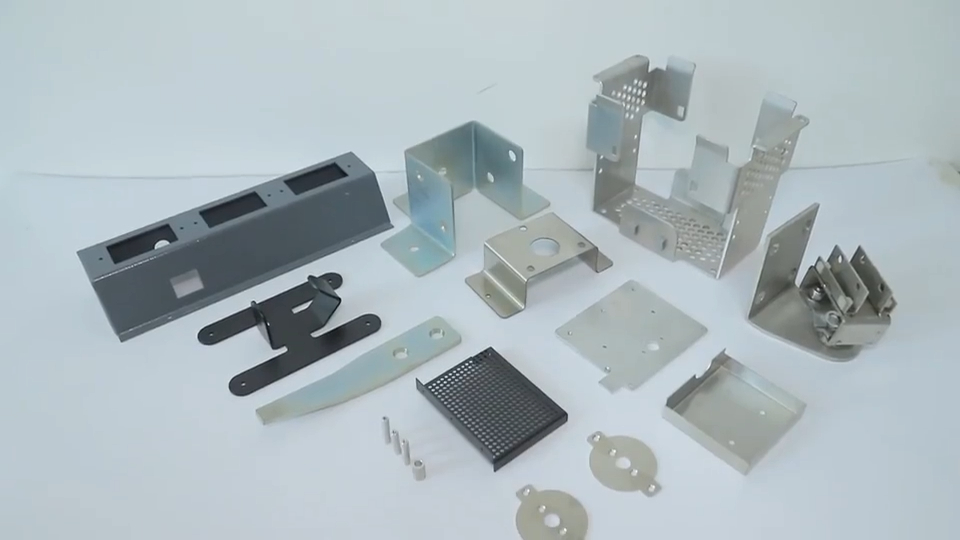

is a professional supplier founded in for products, engaged in Sheet metal fabrication, CNC machining, CNC milling, CNC turning, Sheet metal bending, stamping, welding, Custom metal parts. Our office is located in ,supports the teams of product design , graphic design, sourcing, domestic sales, international sales and finance. After years accumulation, we have won a good reputation among clients from every part of the world because of our thoughtful customer service, strict quality control, nice designed functional products and competitive prices. In addition, our R&D department have achieved a large amount of patents. We keep our products always up to date. Nowadays, our products have been exported and well accepted by consumers across and so on.

Tags: cnc fabrication service, cnc titanium parts, titanium cnc service, custom brass machining, cnc steel cutting machine

CNC processing also has other names, such as CNC machine tool processing, computer gongs, and called CNC processing center, the main work is to compile processing procedures, the original manual work into computer programming. It is a kind of automatic machine tool controlled by the program. This control system can logically process the program with control code or other symbol instructions, through the computer to decode it, so that the machine tool to perform the prescribed action, through the cutting tool will be blank processing into semi-finished products or finished parts.

CNC machine tool is the abbreviation of digital control machine tool, is a kind of automatic machine tool equipped with the program control system. The control system can logically process the program with control code or other symbolic instructions, and decode it, represent it with coded numbers, and input it into a numerical control device through an information carrier. After processing by the numerical control device issued a variety of control signals, control the movement of machine tools, according to the shape and size requirements of the drawings, automatically processing parts out.

Injection molding is an industrial product production modeling method. Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding and die casting methods. An injection molding machine (referred to as an injection machine or injection molding machine) is the thermoplastic or thermosetting material using plastic molding mold into plastic products of various shapes of the main molding equipment, injection molding is achieved by injection molding machine and mold.

A mechanical keyboard is for the consumer group, the keyboard feel has a higher pursuit of people, these are many modern young people's pursuit of products, there is a more and more popular trend, if you are ready to enter the market, and have their own design, welcome to discuss with us, we will realize your ideas, Compared with competitors, szBERGEK is more reliable in product quality and performance.

Sandblasting process is dry sandblasting abrasives can be steel sand, alumina, quartz sand, silicon carbide, but the most used is quartz sand, according to parts material, surface state, and processing requirements can choose different substances of abrasives.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.