Since established, Bergek CNC aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product cnc turning milling parts or our company, just contact us.

There are a variety of themes, such as bricks, owls, flowers, Lions, etc. , which can be customized according to our choice and the living space that is proposed to be decorated. For example, the lion face brick in the hall can partially reflect the traditional practice of decorating the walls with the body parts of the lion or tiger, which is hunted.

Up, key chains and socks that attract aspiring customers and become ideal gifts are turning the big business around. On last July, Paula Nicklaus, general manager of John Lewis, reported on the return of the \"lipstick effect\" because department stores reported that growth in high-priced goods slowed, but \"spontaneous\" buying activities such as beauty

I printed all the parts with PLA with a resolution of 0, MM, fill amount of 20%, no stand (Considering that you place it in the right direction, one of the stl files). You can find all the files in the following locations: pictures of each part and executed tipe required to print them.

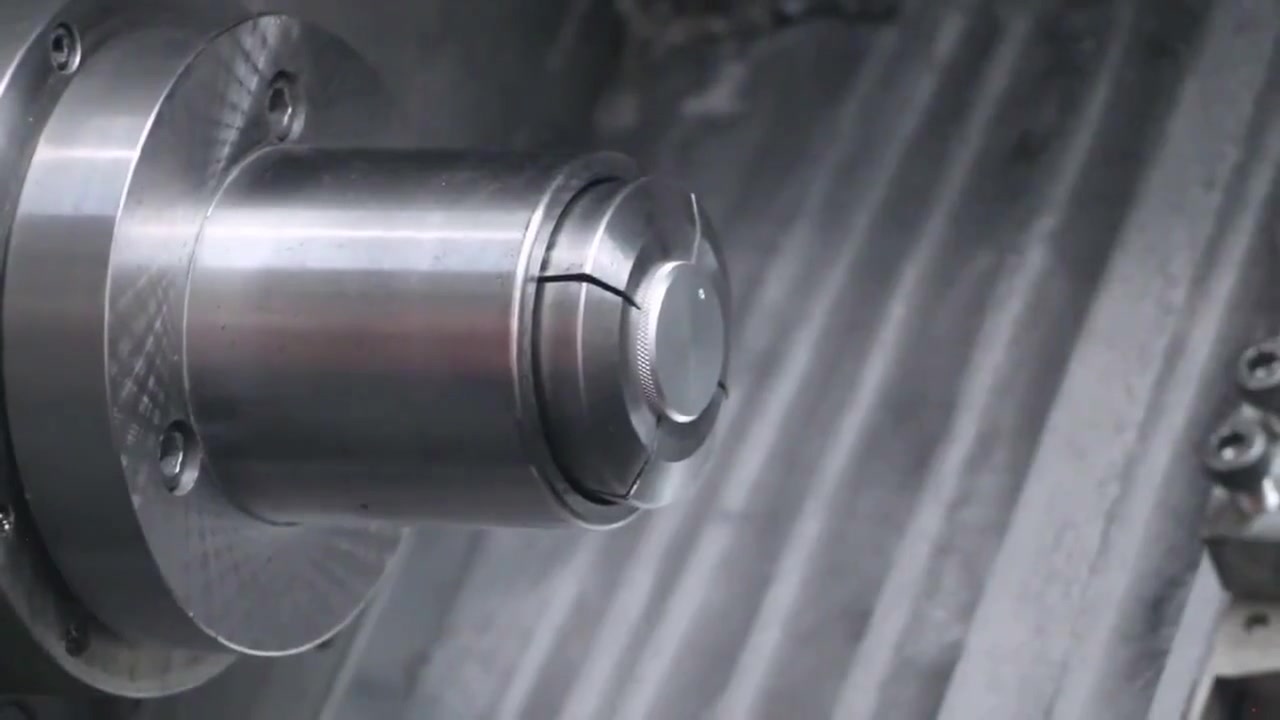

Besides gangs-The style or turret tooling can accommodate a variety of professional processes such as spindle drill bits and tap heads, high-frequency drill bits and mill spindles, grinding spindles and even laser welding and induction hardening equipment. The G300 reclined bed CNC turn-milling center is also shown with bar capacity of up to 3.

was established in the year in . is engaged in offering unmatchable quality products to customers. We are prominent supplier, trader and importer of . Keeping in mind the requirements of the customers, we offer good quality and highly durable products to customers. For distributing the products, we are backed by technical expertise of the market. They know how to meet the requirements of the patron and satisfy their demands. Our Parent company is known for their timely delivery, quality tested array and most reasonable prices. Moreover, our professionals also strive hard and are capable to meet the increasing demands of the market. By providing good quality products, we have maintained a trust worthy position in the market.

Tags: cnc fabrication service, cnc titanium parts, titanium cnc service, custom brass machining, cnc steel cutting machine

CNC processing also has other names, such as CNC machine tool processing, computer gongs, and called CNC processing center, the main work is to compile processing procedures, the original manual work into computer programming. It is a kind of automatic machine tool controlled by the program. This control system can logically process the program with control code or other symbol instructions, through the computer to decode it, so that the machine tool to perform the prescribed action, through the cutting tool will be blank processing into semi-finished products or finished parts.

CNC machine tool is the abbreviation of digital control machine tool, is a kind of automatic machine tool equipped with the program control system. The control system can logically process the program with control code or other symbolic instructions, and decode it, represent it with coded numbers, and input it into a numerical control device through an information carrier. After processing by the numerical control device issued a variety of control signals, control the movement of machine tools, according to the shape and size requirements of the drawings, automatically processing parts out.

Injection molding is an industrial product production modeling method. Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding and die casting methods. An injection molding machine (referred to as an injection machine or injection molding machine) is the thermoplastic or thermosetting material using plastic molding mold into plastic products of various shapes of the main molding equipment, injection molding is achieved by injection molding machine and mold.

A mechanical keyboard is for the consumer group, the keyboard feel has a higher pursuit of people, these are many modern young people's pursuit of products, there is a more and more popular trend, if you are ready to enter the market, and have their own design, welcome to discuss with us, we will realize your ideas, Compared with competitors, szBERGEK is more reliable in product quality and performance.

Sandblasting process is dry sandblasting abrasives can be steel sand, alumina, quartz sand, silicon carbide, but the most used is quartz sand, according to parts material, surface state, and processing requirements can choose different substances of abrasives.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.