Since established, Bergek CNC aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product cnc turning machining parts factory or our company, just contact us.

Change and speed of force. Increasing hard drive capacity in a smaller format and at a lower cost allows automakers to afford to install memory in the factory in vehicle media and entertainment systems. Almost all North American cars and trucks have been built-Event data recorder (EDR)Since mid-1990, like a flight data recorder (FDR)

\"Just in case I knew earlier.Yes, we have all been there.Fortunately, there may be two or three symptoms....Before the last turning point in its past.When you try to start the vehicle, the steering of the engine takes longer than the traditional start-up time.When your battery control is weak, check that the engine light will appear from time to time.Vehicle batteries usually have some translucent bundles so that you can observe fluid measurements to a large extent.If the fluid is measured under the lead plate: (dangerous conductor:) it is an incredible opportunity to try the battery and the charging system.

Accurate and eye-catching)As a template for your metal structure. The actual manufacturing parts are like building a cardboard model, but replace the cardboard and masking tape with a metal and MIG welder. When you have the power of metal, you can do anything and do anything. The sky is the limit; literally. (Some of the most impressive metal structures come from aerospace technology).

Prior to surface treatment and processing, the bonded material will be subjected to appropriate aging treatment. This is to prevent the recessed glue seam and stabilize the size before processing. Workmanship --All size parts should be manufactured well and in accordance with the various grades defined below. Thickness --The maximum finished thickness available depends on the width of the workpiece.

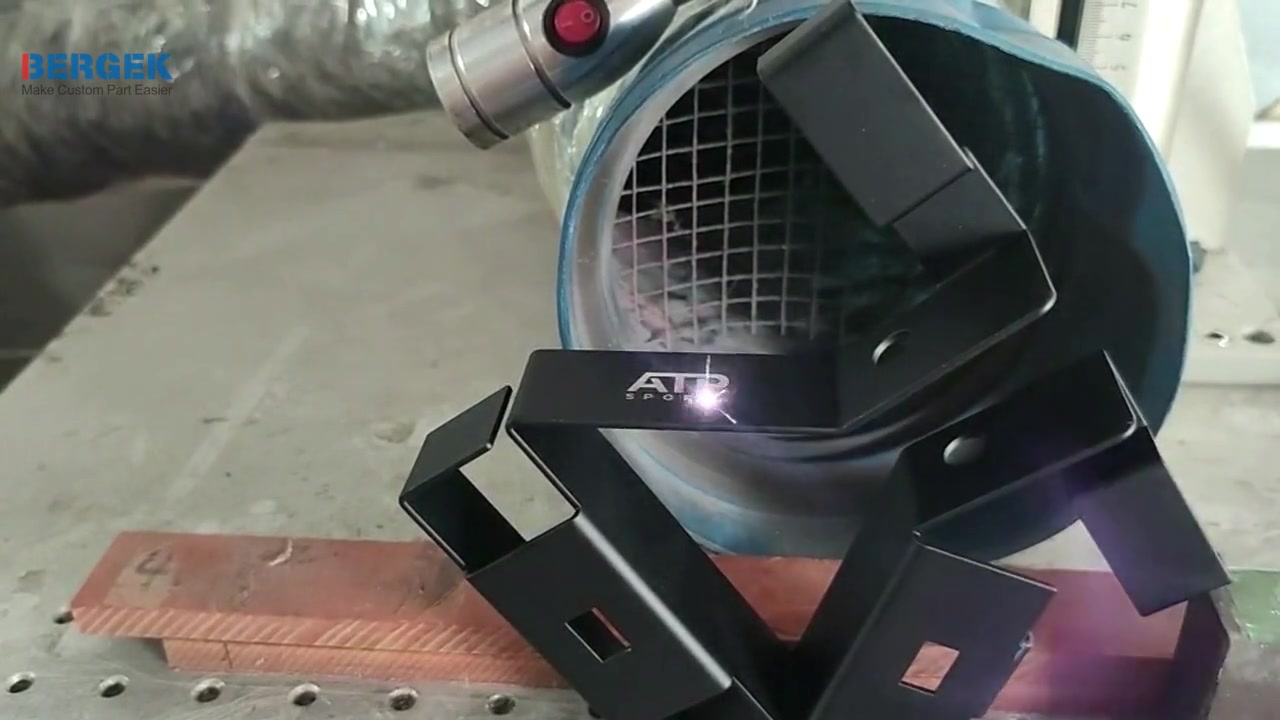

starts its journey in . We are specialized in production of best in class Sheet metal fabrication, CNC machining, CNC milling, CNC turning, Sheet metal bending, stamping, welding, Custom metal parts, we are based in and our roots are in every Corner of China. We are the fastest growing company in . We are the leading Wholesale Trader of Sheet metal fabrication, CNC machining, CNC milling, CNC turning, Sheet metal bending, stamping, welding, Custom metal parts, etc. Our offered products are of superior quality.

Tags: cnc fabrication service, cnc titanium parts, titanium cnc service, custom brass machining, cnc steel cutting machine

CNC processing also has other names, such as CNC machine tool processing, computer gongs, and called CNC processing center, the main work is to compile processing procedures, the original manual work into computer programming. It is a kind of automatic machine tool controlled by the program. This control system can logically process the program with control code or other symbol instructions, through the computer to decode it, so that the machine tool to perform the prescribed action, through the cutting tool will be blank processing into semi-finished products or finished parts.

CNC machine tool is the abbreviation of digital control machine tool, is a kind of automatic machine tool equipped with the program control system. The control system can logically process the program with control code or other symbolic instructions, and decode it, represent it with coded numbers, and input it into a numerical control device through an information carrier. After processing by the numerical control device issued a variety of control signals, control the movement of machine tools, according to the shape and size requirements of the drawings, automatically processing parts out.

Injection molding is an industrial product production modeling method. Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding and die casting methods. An injection molding machine (referred to as an injection machine or injection molding machine) is the thermoplastic or thermosetting material using plastic molding mold into plastic products of various shapes of the main molding equipment, injection molding is achieved by injection molding machine and mold.

A mechanical keyboard is for the consumer group, the keyboard feel has a higher pursuit of people, these are many modern young people's pursuit of products, there is a more and more popular trend, if you are ready to enter the market, and have their own design, welcome to discuss with us, we will realize your ideas, Compared with competitors, szBERGEK is more reliable in product quality and performance.

Sandblasting process is dry sandblasting abrasives can be steel sand, alumina, quartz sand, silicon carbide, but the most used is quartz sand, according to parts material, surface state, and processing requirements can choose different substances of abrasives.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.