Since established, Bergek CNC aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product cnc turned components or our company, just contact us.

The cooling design uses a unique technology that does not require complex gas circulation and cooling systems to maintain proper operating temperatures. The diffusion-The cooling design eliminates the ease of wear and movement of components that require daily maintenance. The diffusion-A cooling laser, also known as a wave duct laser, is a \"no flow\" laser with a cavity design for correcting optics and wave duct structures to produce beams close to Gaussian.

Computer-assisted settingsA system developed by Michael wegginginc. Combine a fully computerized mold system with mechanical digital tool setup to provide quick CNC setup and improved organizational benefits. The computer directly linked to the toolroom stores all the information needed to complete the profile settings, including: Tool list, measured tool size, tool layout details, and required profile size.

Fog lights are only allowed at low-Visibility conditions. Image: Tracey Nearmy/AAPSource: AAPBut if these lights are turned on under normal driving conditions, they may cause the approaching vehicle to be temporarily blinded by the lights, thus to the otherThey can also lead to rearThe accident ended as the driver mistaken the bright red rear fog light for the brake light.

The monthly plate shape grass1 ceiling lightIt is the largest cut-in router in China. It does take some practice to do this teaching, but it is not difficult. All the components in this structure are crafted with the plunge router. This involves the use of homemade molds (templates). In addition, it mainly exists in many partial circles.

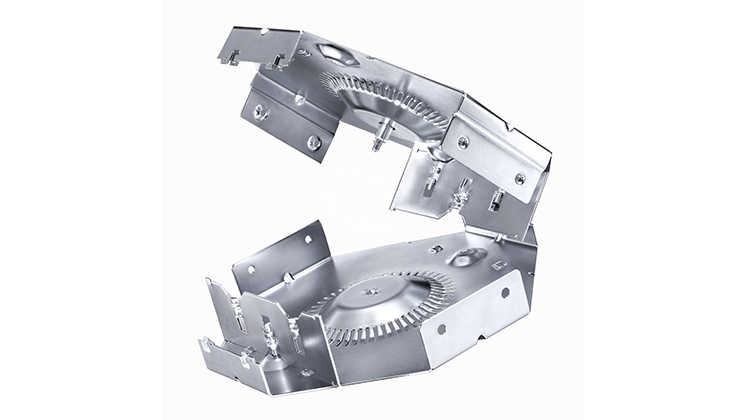

starts its journey in . We are specialized in production of best in class Sheet metal fabrication, CNC machining, CNC milling, CNC turning, Sheet metal bending, stamping, welding, Custom metal parts, we are based in and our roots are in every Corner of China. We are the fastest growing company in . We are the leading Wholesale Trader of Sheet metal fabrication, CNC machining, CNC milling, CNC turning, Sheet metal bending, stamping, welding, Custom metal parts, etc. Our offered products are of superior quality.

Tags: cnc fabrication service, cnc titanium parts, titanium cnc service, custom brass machining, cnc steel cutting machine

CNC processing also has other names, such as CNC machine tool processing, computer gongs, and called CNC processing center, the main work is to compile processing procedures, the original manual work into computer programming. It is a kind of automatic machine tool controlled by the program. This control system can logically process the program with control code or other symbol instructions, through the computer to decode it, so that the machine tool to perform the prescribed action, through the cutting tool will be blank processing into semi-finished products or finished parts.

CNC machine tool is the abbreviation of digital control machine tool, is a kind of automatic machine tool equipped with the program control system. The control system can logically process the program with control code or other symbolic instructions, and decode it, represent it with coded numbers, and input it into a numerical control device through an information carrier. After processing by the numerical control device issued a variety of control signals, control the movement of machine tools, according to the shape and size requirements of the drawings, automatically processing parts out.

Injection molding is an industrial product production modeling method. Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding and die casting methods. An injection molding machine (referred to as an injection machine or injection molding machine) is the thermoplastic or thermosetting material using plastic molding mold into plastic products of various shapes of the main molding equipment, injection molding is achieved by injection molding machine and mold.

A mechanical keyboard is for the consumer group, the keyboard feel has a higher pursuit of people, these are many modern young people's pursuit of products, there is a more and more popular trend, if you are ready to enter the market, and have their own design, welcome to discuss with us, we will realize your ideas, Compared with competitors, szBERGEK is more reliable in product quality and performance.

Sandblasting process is dry sandblasting abrasives can be steel sand, alumina, quartz sand, silicon carbide, but the most used is quartz sand, according to parts material, surface state, and processing requirements can choose different substances of abrasives.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.