Since established, Bergek CNC aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product precision cnc lathe parts or our company, just contact us.

To hide the game console in the candy box, I keep the front and border unchanged. I just removed the sticker from the back and put all the parts in. This candy box does not use any glue, so it is easy to separate the lid with some force: PAfter separate the lid and align the Pro Micro board USB plug to the tablet socket.

Be sure to advancedrill! In the first photo, I am installing the back of the middle part. Continue to add your work. I also strongly recommend that you sink holes, otherwise the screws may not be flush, resulting in a gap between the middle section and the cabinet. I decided to like the front of the middle section and cut the vents and USB hub mounting holes with my CNC.

\"We just want them to do it. \"Earlier this year, the environmental protection company released a study showing that some of the most popular plastic bottles sold across Canada showed\" very significant \"levels of BPA. In this study, nine different polycarbonate bottles from three different major manufacturers were heated during the testing process and for chemicals in five to eight parts per billion

Up applications connect materials and methods using welding materials or adhesives. The placement accuracy is improved; Many manufacturers claim 5 to 10 M precision, band /-1 I can enjoy the extra cost. These die clamps, combined with the latest advances in line-connecting equipment, allow very precise line length, ring height and ring shape control, allows COB with lead connections to compete with the flip chip in RF applications where the accuracy of parasitic reactions on each I/O pad of the chip is a factor in the overall design.

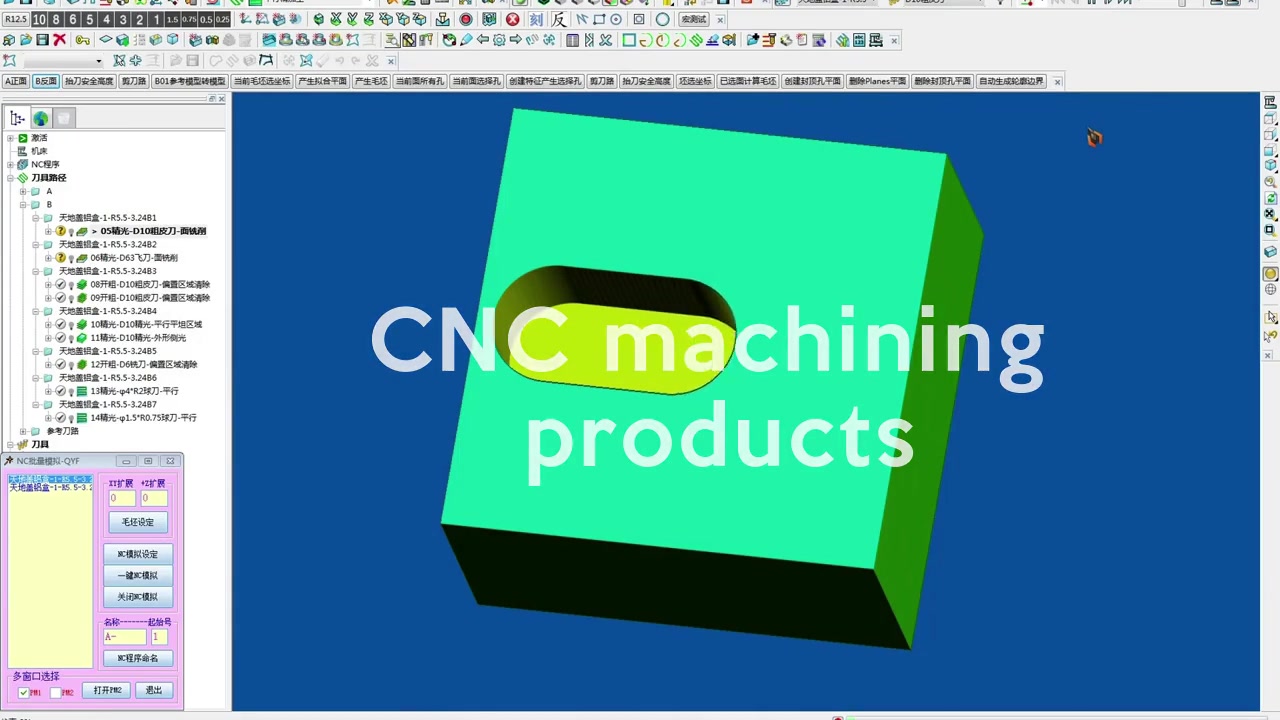

is a modern company with INNOVATION, R&D and MANUFACTURING, was found in and focus on the field. With a number of patented technologies, and own brand with 'Bergek CNC'. We have Sheet metal fabrication, CNC machining, CNC milling, CNC turning, Sheet metal bending, stamping, welding, Custom metal parts etc.

Tags: cnc fabrication service, cnc titanium parts, titanium cnc service, custom brass machining, cnc steel cutting machine

CNC processing also has other names, such as CNC machine tool processing, computer gongs, and called CNC processing center, the main work is to compile processing procedures, the original manual work into computer programming. It is a kind of automatic machine tool controlled by the program. This control system can logically process the program with control code or other symbol instructions, through the computer to decode it, so that the machine tool to perform the prescribed action, through the cutting tool will be blank processing into semi-finished products or finished parts.

CNC machine tool is the abbreviation of digital control machine tool, is a kind of automatic machine tool equipped with the program control system. The control system can logically process the program with control code or other symbolic instructions, and decode it, represent it with coded numbers, and input it into a numerical control device through an information carrier. After processing by the numerical control device issued a variety of control signals, control the movement of machine tools, according to the shape and size requirements of the drawings, automatically processing parts out.

Injection molding is an industrial product production modeling method. Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding and die casting methods. An injection molding machine (referred to as an injection machine or injection molding machine) is the thermoplastic or thermosetting material using plastic molding mold into plastic products of various shapes of the main molding equipment, injection molding is achieved by injection molding machine and mold.

A mechanical keyboard is for the consumer group, the keyboard feel has a higher pursuit of people, these are many modern young people's pursuit of products, there is a more and more popular trend, if you are ready to enter the market, and have their own design, welcome to discuss with us, we will realize your ideas, Compared with competitors, szBERGEK is more reliable in product quality and performance.

Sandblasting process is dry sandblasting abrasives can be steel sand, alumina, quartz sand, silicon carbide, but the most used is quartz sand, according to parts material, surface state, and processing requirements can choose different substances of abrasives.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.