Since established, Bergek CNC aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product cnc metal bending or our company, just contact us.

Cold copper mold. The middle tank and the melted metal move down about an inch, and then the middle tank bounces back to its original position. When the middle tank is repeatedly moving, this movement allows the flow of partially solidified steel to move down. The contact of the molten steel with the middle tank of reciprocating cooling will produce a solidified shell on the quality of the molten steel and allow the steel to move and guide without giving the chance of hot metal welding a continuous casting machine.

I removed all the spade connectors and replaced them. Now I have only one clue. Toyota has decided to use LEDs installed with a pin, so they need to install LEDs that are different from those installed with only wires. They use steel plates as buses between LEDs. Each LED is pressed onto a metal plate.

Prices as of June 1, 2016)Both drawers slide on metal tracks and are built in-Railings are hung on all sides. The unit has two drawers that can support letters or legal documents. Most importantly, this is real solid wood, so it will stay still for a long time. Classy 2-What makes the standard filing cabinet look so uncomfortable is the plain and monotonous look or business style

Texture and stained glass are another way to reflect your own style, says Anderson. What he sees is the glass used to surround the top of the stove, the tailgate and the front of the cabinet. Mix your metal gold, brass and other yellowTone metal finishes have been popular for several years, and now White metal finishes like Chrome, white wax and stainless steel are also popular, Yip said.

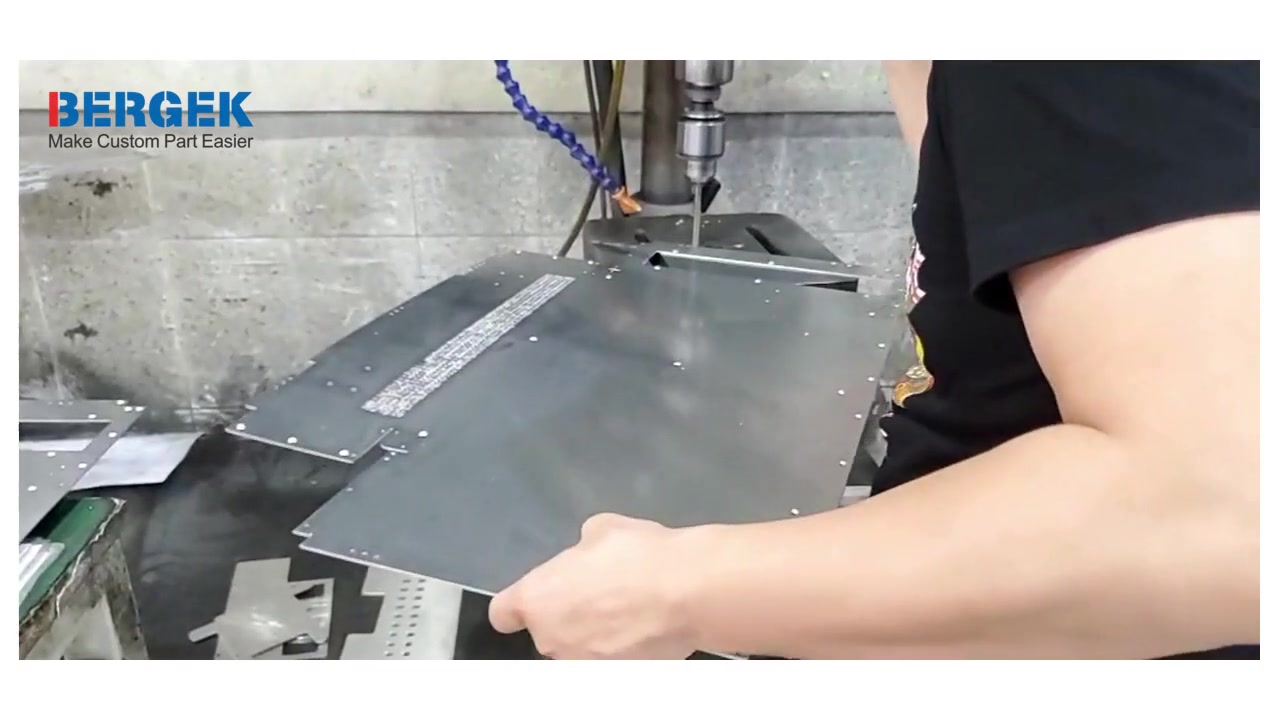

established in , is a professional manufacturer engaged in the research, development, production, sale and service of Sheet metal fabrication, CNC machining, CNC milling, CNC turning, Sheet metal bending, stamping, welding, Custom metal parts. We are located in with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment and we have passed ISO9001 certification, and obtained High-tech Enterprise certificate. Selling well in many cities and provinces around China, our products are also exported to clients in such countries and regions as . Except our own products, we provide OEM services and accept customized order as well. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We sincerely welcome friends from all over the world to visit our company and cooperate with us on the basis of long-term mutual benefits. We are looking forward to receiving your enquiries soon.

Tags: cnc fabrication service, cnc titanium parts, titanium cnc service, custom brass machining, cnc steel cutting machine

CNC processing also has other names, such as CNC machine tool processing, computer gongs, and called CNC processing center, the main work is to compile processing procedures, the original manual work into computer programming. It is a kind of automatic machine tool controlled by the program. This control system can logically process the program with control code or other symbol instructions, through the computer to decode it, so that the machine tool to perform the prescribed action, through the cutting tool will be blank processing into semi-finished products or finished parts.

CNC machine tool is the abbreviation of digital control machine tool, is a kind of automatic machine tool equipped with the program control system. The control system can logically process the program with control code or other symbolic instructions, and decode it, represent it with coded numbers, and input it into a numerical control device through an information carrier. After processing by the numerical control device issued a variety of control signals, control the movement of machine tools, according to the shape and size requirements of the drawings, automatically processing parts out.

Injection molding is an industrial product production modeling method. Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding and die casting methods. An injection molding machine (referred to as an injection machine or injection molding machine) is the thermoplastic or thermosetting material using plastic molding mold into plastic products of various shapes of the main molding equipment, injection molding is achieved by injection molding machine and mold.

A mechanical keyboard is for the consumer group, the keyboard feel has a higher pursuit of people, these are many modern young people's pursuit of products, there is a more and more popular trend, if you are ready to enter the market, and have their own design, welcome to discuss with us, we will realize your ideas, Compared with competitors, szBERGEK is more reliable in product quality and performance.

Sandblasting process is dry sandblasting abrasives can be steel sand, alumina, quartz sand, silicon carbide, but the most used is quartz sand, according to parts material, surface state, and processing requirements can choose different substances of abrasives.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.