The content of laser cutting processing technology can be roughly combed as follows: laser removal, such as laser drilling, etc.; Laser connection; Such as metal laser welding machine; Laser surface modification materials, such as laser quenching and tempering treatment (laser hardening primer, laser remelting, laser cladding); Laser production and manufacturing of new materials, such as laser calcination, laser preparation of polymer materials;

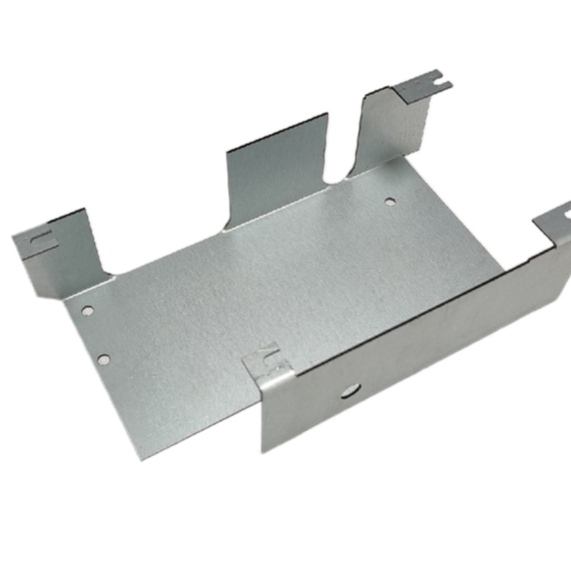

Laser cutting parts utilize advanced technology for precision processing, including laser removal, connection, surface modification, and manufacturing of new materials. The laser cutting machine tools used in the process apply laser principle technology to efficiently produce parts. Through laser processing connection and surface modification materials, the internal organizational structure of the laser parts is transformed for enhanced functionality and durability.

Team strength is at the core of our precision processing capabilities with our laser cutting parts. Our expert team of engineers and technicians are equipped with advanced technology and expertise to ensure unparalleled precision and quality in every part we produce. Our collaborative approach and dedication to continuous improvement drive us to deliver exceptional results for our customers. With a strong emphasis on teamwork, communication, and problem-solving, our team is able to tackle any challenge and exceed expectations. Trust in our team's strength to provide you with the highest quality laser cutting parts for your precision processing needs.

At our company, our team strength lies in our collective expertise in laser cutting technology. We have a dedicated team of highly skilled engineers and technicians who are experienced in delivering precision processing solutions using advanced laser cutting technology. Our team's attention to detail, problem-solving skills, and commitment to quality ensure that we consistently produce top-notch laser cutting parts that meet the highest industry standards. With a strong emphasis on collaboration and innovation, our team is always striving to push the boundaries of what is possible in laser cutting, allowing us to provide our customers with cutting-edge solutions for their unique needs.

Laser-cutting molding technology

The content of laser cutting processing technology can be roughly combed as follows: laser removal, such as laser drilling, etc.; Laser connection; Such as metal laser welding machine; Laser surface modification materials, such as laser quenching and tempering treatment (laser hardening primer, laser remelting, laser cladding); Laser production and manufacturing of new materials, such as laser calcination, laser preparation of polymer materials; Laser parts processing, such as laser parts rapid prototyping technology production and processing.

Main equipment and introduction: Rapid prototyping and laser cutting training room have 3D printing machine tools and laser cutting machine tools. The laser cutting machine uses laser principle technology to process parts, and 3D printing uses rapid prototyping methods to complete product design and sample processing, which greatly improves the speed of trial production of new products and product replacement efficiency.

Among them, are laser cutting processing connection, laser surface modification materials, laser manufacturing new materials, and laser parts internal organizational structure transformation. It should be emphasized that some processing methods are not only surface-modified materials but also towards the rapid production of metal parts by laser. That's what laser cladding means, for example.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.