The content of laser cutting processing technology can be roughly combed as follows: laser removal, such as laser drilling, etc.; Laser connection; Such as metal laser welding machine; Laser surface modification materials, such as laser quenching and tempering treatment (laser hardening primer, laser remelting, laser cladding); Laser production and manufacturing of new materials, such as laser calcination, laser preparation of polymer materials;

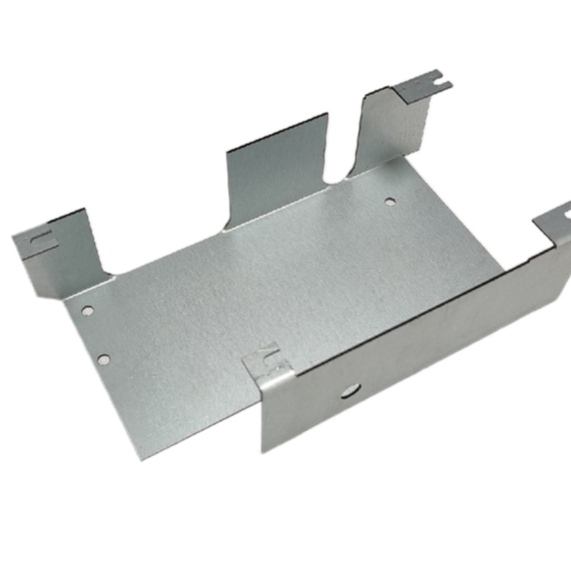

Our laser cutting parts utilize advanced technology to ensure precision cutting for a wide range of materials. With high cutting speeds and accuracy, our products provide superior quality results for various manufacturing applications. The durability and efficiency of our laser cutting parts make them a reliable choice for businesses looking to streamline their production processes.

At our company, we specialize in providing advanced technology for precision cutting with our laser cutting parts. With years of experience and expertise in the industry, we are committed to delivering high-quality products that meet the highest standards of precision and accuracy. Our team of professionals is dedicated to ensuring that our customers receive the best possible products and service. We take pride in our ability to innovate and stay ahead of the curve when it comes to technology and advancements in the field. Trust us to provide you with the cutting-edge solutions you need for all your cutting needs.

With decades of experience in precision cutting technology, our company is renowned for our expertise in laser cutting parts. Our advanced technology allows for the most precise and accurate cuts, ensuring that every part meets the highest standards of quality. Our team of skilled professionals are dedicated to delivering exceptional results, no matter the complexity of the project. We take pride in our commitment to customer satisfaction and are always striving to exceed expectations. Trust us to provide you with the best laser cutting parts on the market and experience the difference that advanced technology can make in your projects.

Laser-cutting molding technology

The content of laser cutting processing technology can be roughly combed as follows: laser removal, such as laser drilling, etc.; Laser connection; Such as metal laser welding machine; Laser surface modification materials, such as laser quenching and tempering treatment (laser hardening primer, laser remelting, laser cladding); Laser production and manufacturing of new materials, such as laser calcination, laser preparation of polymer materials; Laser parts processing, such as laser parts rapid prototyping technology production and processing.

Main equipment and introduction: Rapid prototyping and laser cutting training room have 3D printing machine tools and laser cutting machine tools. The laser cutting machine uses laser principle technology to process parts, and 3D printing uses rapid prototyping methods to complete product design and sample processing, which greatly improves the speed of trial production of new products and product replacement efficiency.

Among them, are laser cutting processing connection, laser surface modification materials, laser manufacturing new materials, and laser parts internal organizational structure transformation. It should be emphasized that some processing methods are not only surface-modified materials but also towards the rapid production of metal parts by laser. That's what laser cladding means, for example.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.