Five-axis machining center is a kind of high technology content, high precision specialized for processing complex surface machine tool, this machine tool system for a country's aviation, aerospace, military, scientific research, precision equipment, high precision medical equipment, and other industries, has a decisive influence.

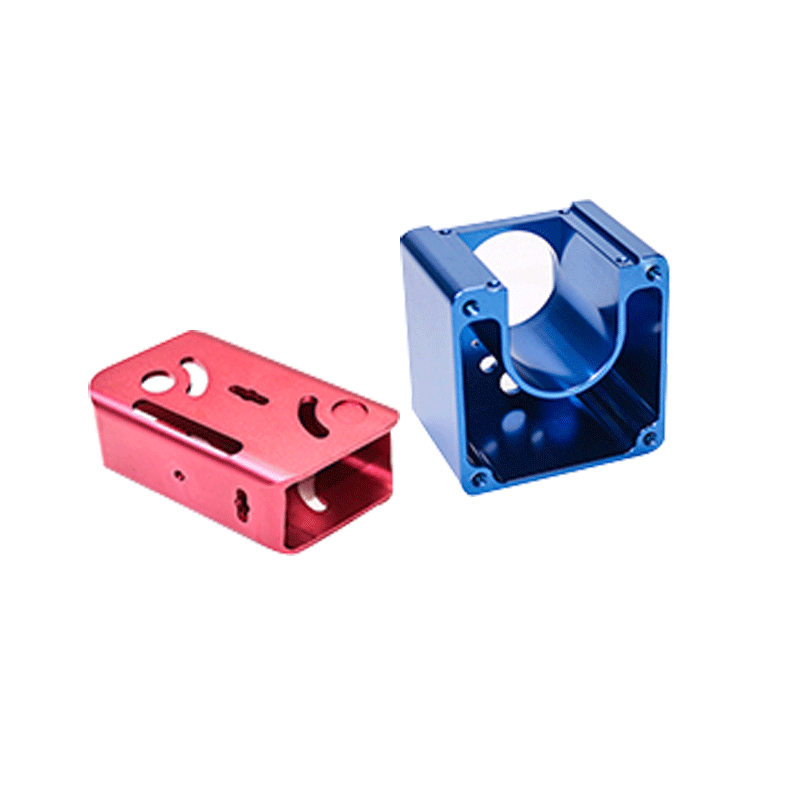

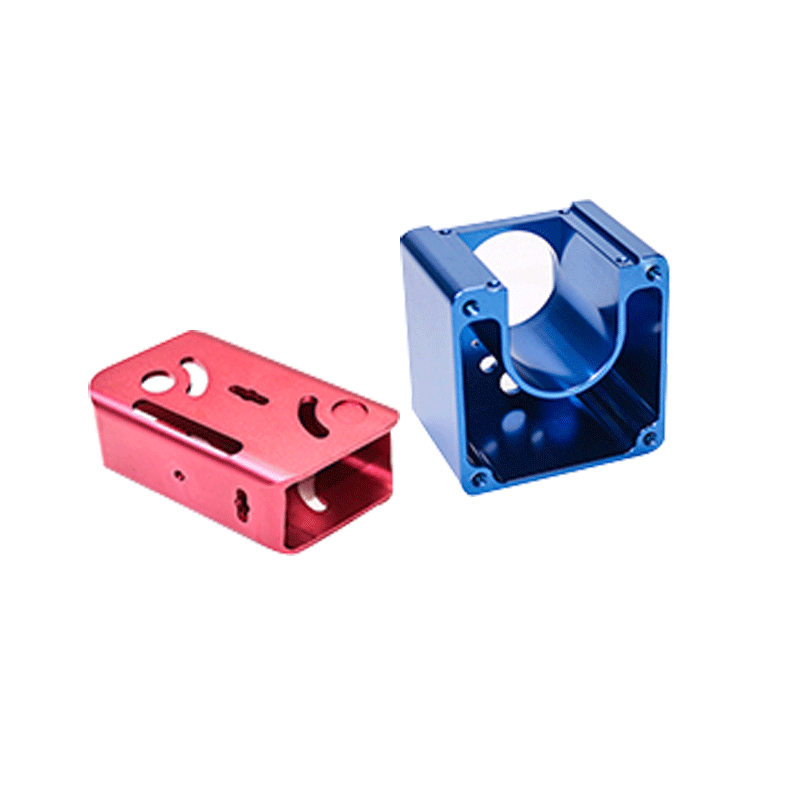

Set up years ago, Bergek CNC is a professional manufacturer and also a supplier with strong capabilities in production, design, and R&D. cnc machined parts Having devoted a lot to product development and service quality improvement, we have established a high reputation in the markets. We promise to provide every customer throughout the world with prompt and professional service covering the pre-sales, sales, and after-sales services. No matter where you are or what business you are engaged in, we'd love to help you deal with any issue. If you want to know more details about our new product cnc machined parts or our company, feel free to contact us. Simultaneously, the use of concept can make cnc machined parts more .

Five-axis machining center is a kind of high technology content, high precision specialized for processing complex surface machine tool, this machine tool system for a country's aviation, aerospace, military, scientific research, precision equipment, high precision medical equipment, and other industries, has a decisive influence.

The five-axis machining center is particularly suitable for processing molds with complex geometric shapes. It has the following advantages:

1, in the processing of deep, steep cavity, artifacts or additional rotary spindle head and swing to create the best process conditions for the machining of the vertical milling cutter, and avoid cutting tools and tool holder and the cavity wall collision, reduce the cutter when processing the jitter and the risk of tool breakage, thus to improve the quality of the surface of the mold, the processing efficiency and cutting tool durability.

2, five-axis linkage machining center technology to remove the workpiece in the complex Angle positioning required for multiple debugging cards. This not only saves time, but also greatly reduces the error, and saves the expensive cost of the fixture required to install the workpiece in place.

3. Enables machine tools to process complex parts impossible otherwise, including the drilling, cavity recess, and taper machining commonly required on complex surfaces.

4, through the use of a shorter tool, can be completed once the processing of the whole parts, do not need to install the card again or use the same 3 axis processing required in the longer tool, and can be delivered in a shorter time, the surface quality of the parts is also ideal.

As the driving force of national economic growth and technological upgrading, the machinery, and equipment manufacturing industry marked by a five-axis linkage will progress together with the development of new and high technologies and emerging industries.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.